A kind of preparation method of low stress TIW film

A low-stress, thin-film technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of decreased interface bonding strength, poor uniformity, and cracked substrate and film, etc. Availability and generalizability, the effect of increasing film nucleation rate and reducing growth stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below with reference to the accompanying drawings and specific examples, but the embodiments of the present invention include but are not limited to the scopes indicated in the following examples.

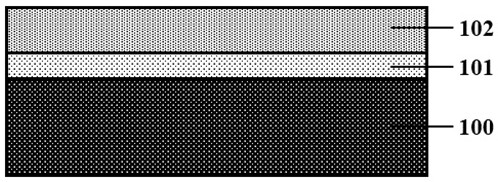

[0022] refer to figure 1 , a schematic diagram of the structure of a low-stress TiW thin film, which sequentially includes a substrate, a TiW seed thin film layer, and a TiW main thin film layer from bottom to top. In order to achieve the above purpose, the present invention provides a method for preparing a two-step PVD sputtering low-stress TiW thin film. The main sputtering parameters include DC / RF power, deposition time, argon flow rate, and chamber vacuum pressure. Using the stable growth rate of PVD sputtering method, the deposition power and time are adjusted to precisely control the two-step TiW thin film.

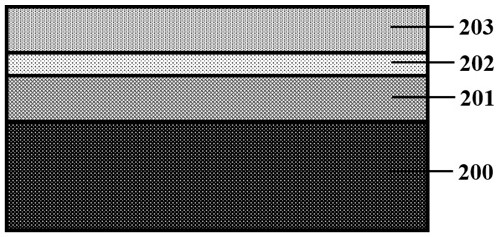

[0023] refer to figure 2 , a schematic diagram of the structure of a two-step PVD sputtering low-str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com