Method for preparing platinum-aluminum coating

A technology of aluminum coating and aluminizing, which is applied in the direction of coating, metal material coating process, solid diffusion coating, etc., can solve the problem that the aluminized coating cannot be used for a long time, and achieve the potential of prolonging the life of the engine and increasing the adhesion Sexuality, anti-diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

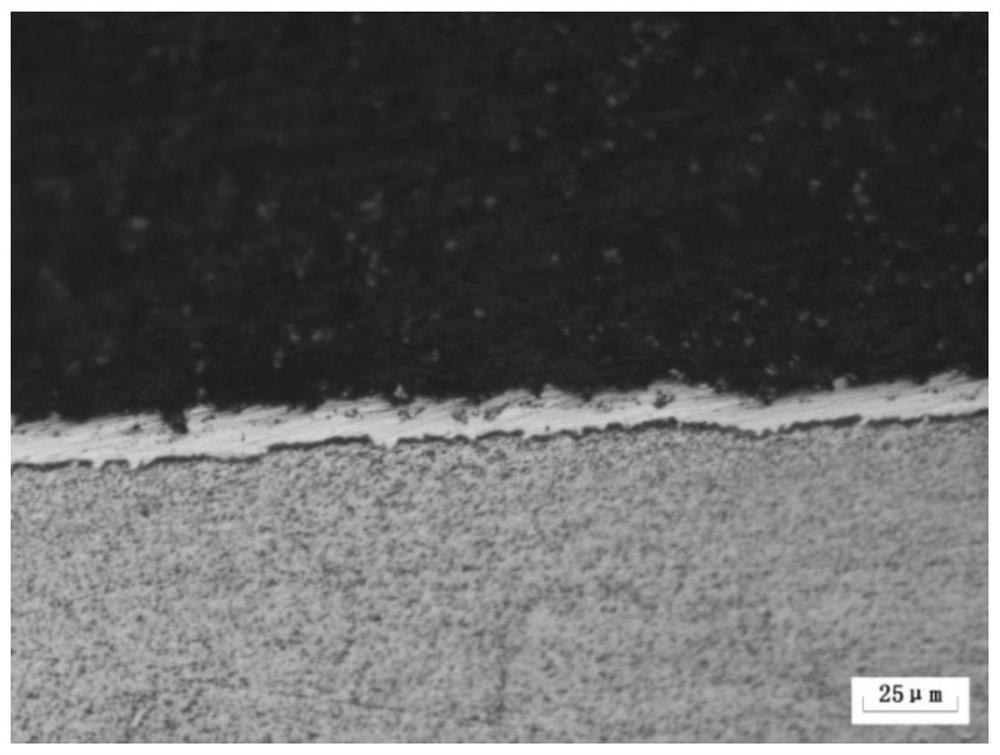

[0047] The method for preparing the platinum-aluminum coating of the present embodiment specifically comprises the following steps:

[0048] (1) Platinum electroplating: Platinum electroplating with a thickness of 6 μm is applied to parts of DD412 single crystal alloy materials that require platinum-aluminum coatings;

[0049] It is required that the electroplating platinum layer has no defects such as peeling, wrinkles and peeling;

[0050] (2) Cleaning: Clean up the oil and other dirt on the surface of the parts;

[0051] In step (2), corundum sand with a particle size of less than or equal to 200 meshes is used at a pressure of 1 × 10 5 Dry sand blowing under the condition of Pa to remove surface dirt.

[0052] (3) Pre-diffusion treatment: put the parts under vacuum pressure ≤ 1.33×10 -1 Pa, heat preservation in a vacuum furnace at a temperature of 1000°C for 2 hours;

[0053] In this step, the role of pre-diffusion is to allow the platinum-coated layer to interdiffuse ...

Embodiment 2

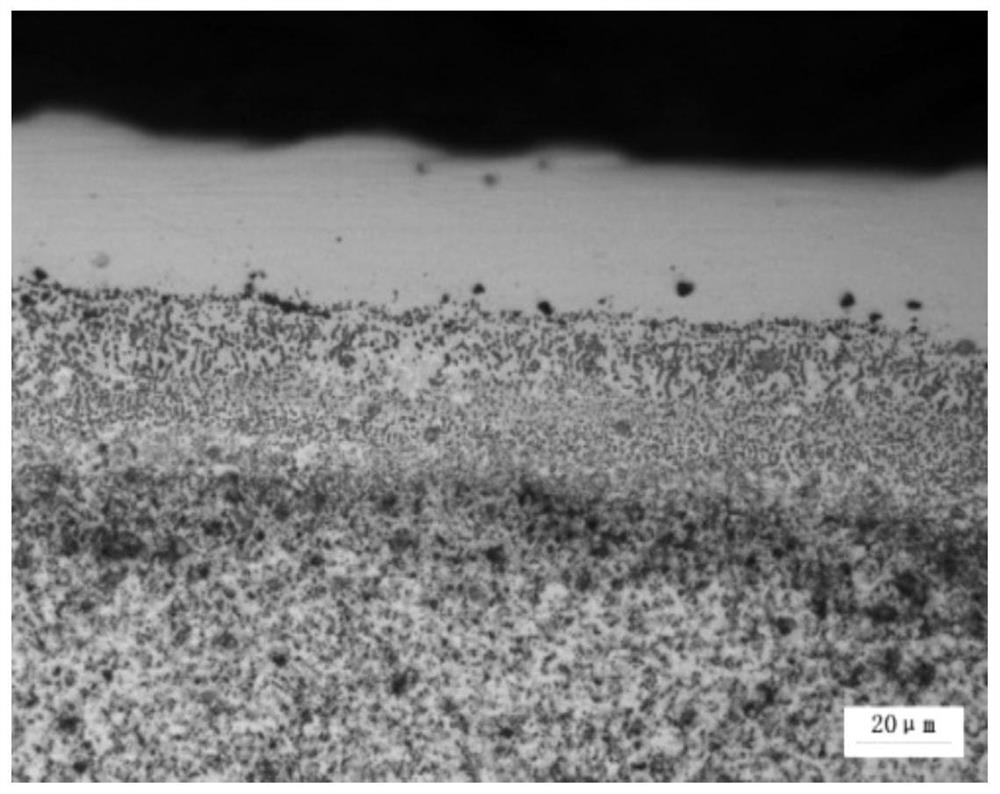

[0067] The method for preparing a platinum-aluminum coating of the present invention specifically comprises the following steps:

[0068] (1) Platinum electroplating: Platinum electroplating with a thickness of 4 μm is applied to the parts of DD412 single crystal alloy material parts that need to be prepared with platinum-aluminum coating;

[0069] It is required that the electroplating platinum layer has no defects such as peeling, wrinkles and peeling;

[0070] (2) Cleaning: Clean up the oil and other dirt on the surface of the parts;

[0071] In step (2), corundum sand with a particle size less than or equal to 200 meshes can be used under a pressure of 1.5×10 5 Dry sand blowing under the condition of Pa to remove surface dirt.

[0072] (3) Pre-diffusion treatment: put the parts under vacuum pressure ≤ 1.33×10 -1 Pa, the temperature is 950 ° C for 2.5 hours;

[0073] In step (3), pre-diffusion treatment is performed in a vacuum furnace.

[0074] In this step, the role ...

Embodiment 3

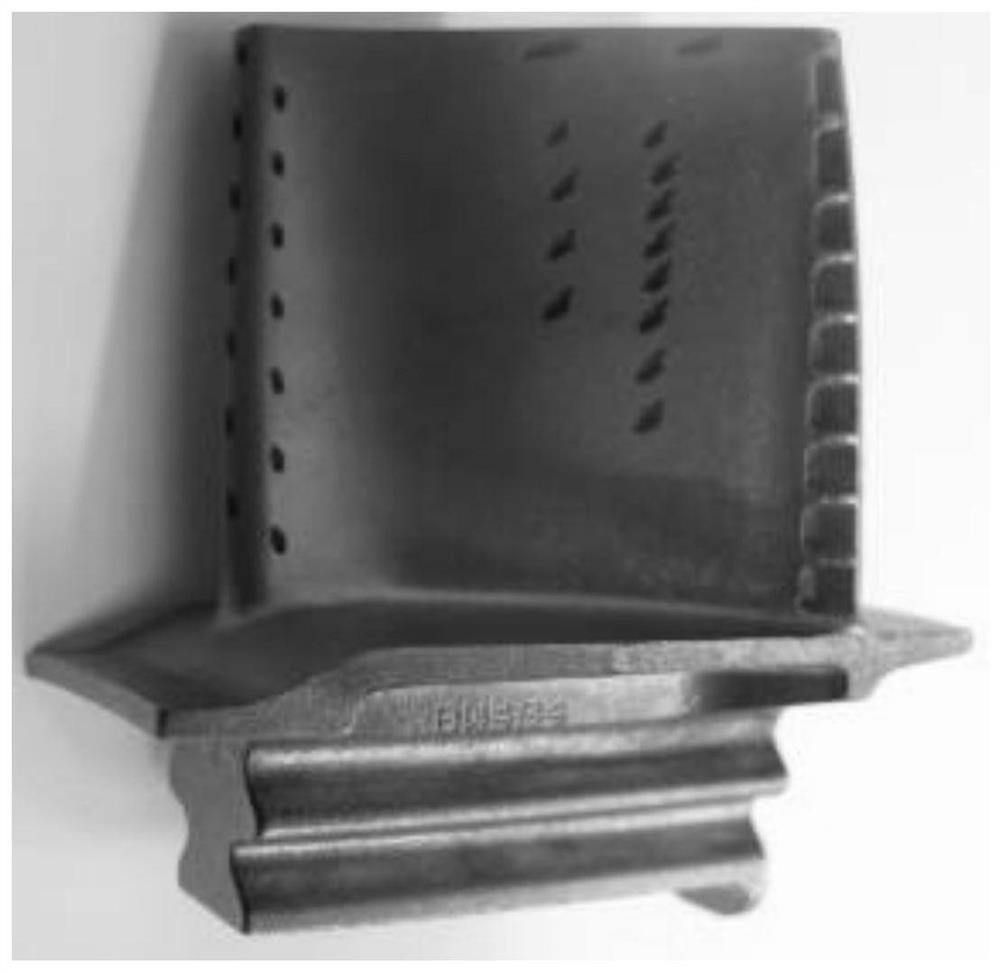

[0091] The method for preparing a platinum-aluminum coating of the present invention specifically comprises the following steps:

[0092] (1) Platinum electroplating: Platinum electroplating with a thickness of 8 μm is applied to parts of single crystal alloy materials that need to be prepared with a platinum-aluminum coating;

[0093] It is required that the electroplating platinum layer has no defects such as peeling, wrinkles and peeling;

[0094] (2) Cleaning: Clean up the oil and other dirt on the surface of the parts;

[0095] In step (2), corundum sand with particle size less than or equal to 200 meshes can be used, and the pressure is 1×10 5 Dry sand blowing under the condition of Pa to remove surface dirt.

[0096] (3) Pre-diffusion treatment: put the parts under vacuum pressure ≤ 1.33×10 -1 Pa, the temperature is 1050 ℃ and kept for 1.5h;

[0097] In step (3), pre-diffusion treatment is performed in a vacuum furnace.

[0098] In this step, the role of pre-diffus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com