Method for prolonging service life of high-temperature coating on nickel-based alloy

A coating life, nickel-based alloy technology, applied in metal material coating process, coating, solid-state diffusion coating, etc. It is easy to produce cracks and other problems, and achieve the effects of improving oxidation resistance and corrosion resistance, reducing growth stress, and uniform distribution of Pt elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for improving the service life of a high-temperature coating on a nickel-based alloy, specifically comprising the following steps:

[0028] (1) The sample was polished and cleaned, and then electroplated with Pt; the temperature of the Pt solution during electroplating was 50°C, and the current density was 0.01 A / cm 2 , the deposition time was 1 h, and the thickness of the electroplated Pt was 1 μm; the electroplated samples were cleaned with deionized water and dried.

[0029] (2) The sample after electroplating is embedded and aluminized, and the infiltration agent is composed of aluminum silicon powder and NH 4 F composition, NH in osmotic agent 4 The mass percentage of Cl is 2%; the aluminizing temperature is 1000°C, the temperature is kept for 10h, and the sample is cooled with the furnace.

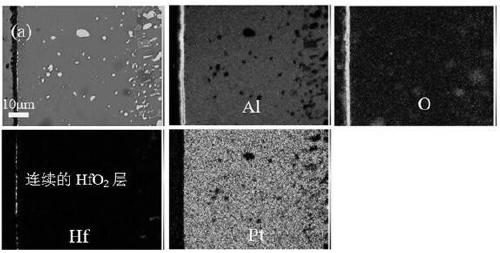

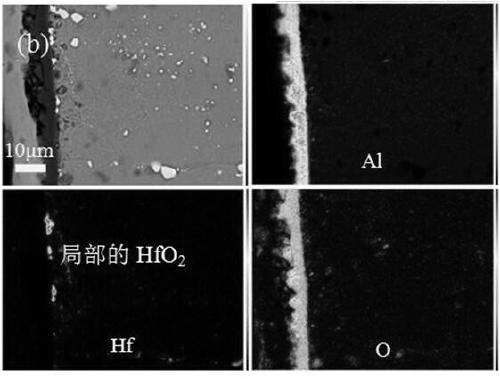

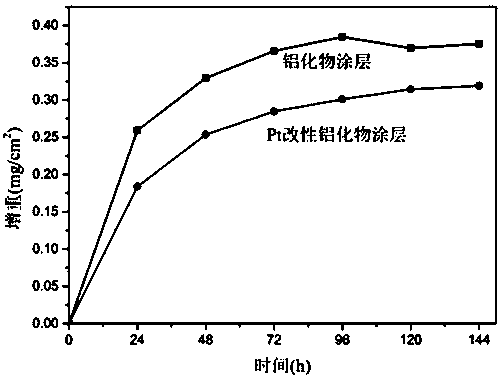

[0030] (3) Pre-oxidize the sample after aluminizing; the oxidation temperature is 1050 °C, and the oxidation time is 48 h.

[0031] (4) The sample after pre-oxidat...

Embodiment 2

[0035] A method for improving the service life of a high-temperature coating on a nickel-based alloy, specifically comprising the following steps:

[0036] (1) The sample is polished and cleaned, and then electroplated with Pt. The temperature of the Pt solution during electroplating is 45°C, and the current density is 0.05A / cm 2 , the deposition time was 1.5h, and the thickness of the electroplated Pt was 1.5 μm; the electroplated samples were cleaned and dried with deionized water.

[0037] (2) The sample after electroplating is embedded and aluminized, and the infiltration agent is composed of aluminum silicon powder and NH 4 Cl composition, NH in osmotic agent 4 The mass percentage of Cl is 2.5%; the aluminizing temperature is 800°C, the temperature is kept for 6 hours, and the sample is cooled with the furnace.

[0038] (3) Pre-oxidize the sample after aluminizing. The oxidation temperature is 900°C and the oxidation time is 50h.

[0039] (4) The pre-oxidized sample ...

Embodiment 3

[0042] A method for improving the service life of a high-temperature coating on a nickel-based alloy, specifically comprising the following steps:

[0043] (1) The sample is polished and cleaned, and then electroplated with Pt. The temperature of the Pt solution during electroplating is 40°C, and the current density is 0.03A / cm 2, the deposition time was 2 h, and the thickness of the electroplated Pt was 2 μm; the electroplated samples were cleaned with deionized water and dried.

[0044] (2) The sample after electroplating is embedded and aluminized, and the infiltration agent is composed of aluminum silicon powder and NH 4 Cl composition, NH in osmotic agent 4 The mass percentage of Cl is 3%; the aluminizing temperature is 900°C, the temperature is kept for 4 hours, and the sample is cooled with the furnace.

[0045] (3) Pre-oxidize the sample after aluminizing, the oxidation temperature is 100°C, and the oxidation time is 40h.

[0046] (4) The samples after pre-oxidatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com