Growth method for controlling grain size of polycrystalline diamond by microwave CVD method

A polycrystalline diamond, grain size technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve problems such as processing difficulties, multi-crack grains, defects, etc., to reduce lattice defects, reduce Effects of growth stress and increased growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

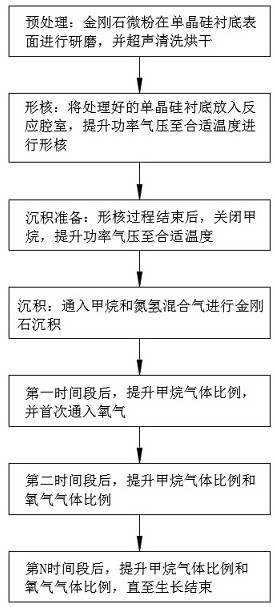

[0050] A kind of microwave CVD method controls the growth method of polycrystalline diamond grain size:

[0051] Pretreatment: Grind the surface of the single crystal silicon substrate with diamond micropowder, and grind for 20 minutes to produce uniform scratches; then place the substrate in alcohol, acetone, and alcohol for ultrasonic cleaning for 10 minutes, and finally use a dryer to dry the substrate drying.

[0052] Open the equipment chamber door, place the processed substrate on the molybdenum holder and place it on the water-cooled deposition table in the reaction chamber, close the chamber door, and vacuum the reaction chamber to a background vacuum of 1×10 -2 below torr.

[0053] Start to feed hydrogen into the reaction chamber, adjust the reaction pressure to 5-10torr, turn on the microwave power supply, adjust the microwave input power to 600-1000W, and excite the plasma.

[0054] Adjust the microwave power and reaction pressure so that the substrate temperature...

Embodiment 2

[0060] A kind of microwave CVD method controls the growth method of polycrystalline diamond grain size:

[0061] Pretreatment: Grind the surface of the molybdenum substrate with diamond micropowder, and grind for 20 minutes to produce uniform scratches; then place the substrate in alcohol, acetone, and alcohol for ultrasonic cleaning for 10 minutes, and finally use a dryer to dry the substrate drying.

[0062] Open the equipment chamber door, place the processed substrate on the molybdenum holder and place it on the water-cooled deposition table in the reaction chamber, close the chamber door, and vacuum the reaction chamber to a background vacuum of 1×10 -2 below torr.

[0063] Start to feed hydrogen into the reaction chamber, adjust the reaction pressure to 5-10torr, turn on the microwave power supply, adjust the microwave input power to 600-1000W, and excite the plasma.

[0064] Adjust the microwave power and reaction pressure so that the substrate temperature is in the r...

Embodiment 3

[0070] A kind of microwave CVD method controls the growth method of polycrystalline diamond grain size:

[0071] Pretreatment: Grind the surface of the single crystal silicon substrate with diamond micropowder, and grind for 20 minutes to produce uniform scratches; then place the substrate in alcohol, acetone, and alcohol for ultrasonic cleaning for 10 minutes, and finally use a dryer to dry the substrate drying.

[0072] Open the equipment chamber door, place the processed substrate on the molybdenum holder and place it on the water-cooled deposition table in the reaction chamber, close the chamber door, and vacuum the reaction chamber to a background vacuum of 1×10 -2 below torr.

[0073] Start to feed hydrogen into the reaction chamber, adjust the reaction pressure to 5-10torr, turn on the microwave power supply, adjust the microwave input power to 600-1000W, and excite the plasma.

[0074] Adjust the microwave power and reaction pressure so that the substrate temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com