A method of manufacturing a light-emitting diode epitaxial wafer

A technology of light-emitting diodes and manufacturing methods, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor crystal quality and poor anti-static ability, and achieve the effects of improving crystal quality, improving anti-static ability and reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

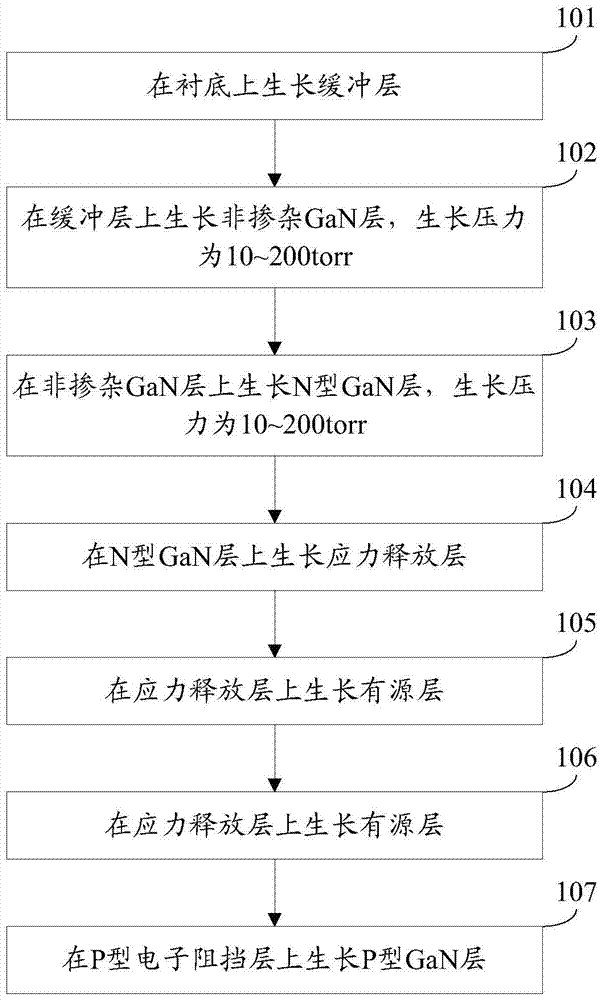

[0026] The embodiment of the present invention provides a method for manufacturing a light-emitting diode epitaxial wafer, which is especially suitable for large-scale epitaxial wafers of 4 inches, 6 inches, and 8 inches. See figure 1 , the manufacturing method includes:

[0027] Step 101: growing a buffer layer on a substrate.

[0028] Specifically, the substrate may be a sapphire substrate.

[0029] In practical application, Metal-Organic Chemical Vapor Deposition (MOCVD) method can be used, with trimethyl (or triethyl) gallium as gallium source, high-purity NH3 as nitrogen source, trimethyl Indium is used as an indium source, trimethylaluminum is used as an aluminum source, silane is selected for n-type doping, and magnesocene is selected for p-type doping to realize the manufacturing method of a light-emitting diode epitaxial wafer provided in this embodiment.

[0030] Step 102: growing a non-doped GaN layer on the buffer layer with a growth pressure of 10-200 torr.

[...

Embodiment 2

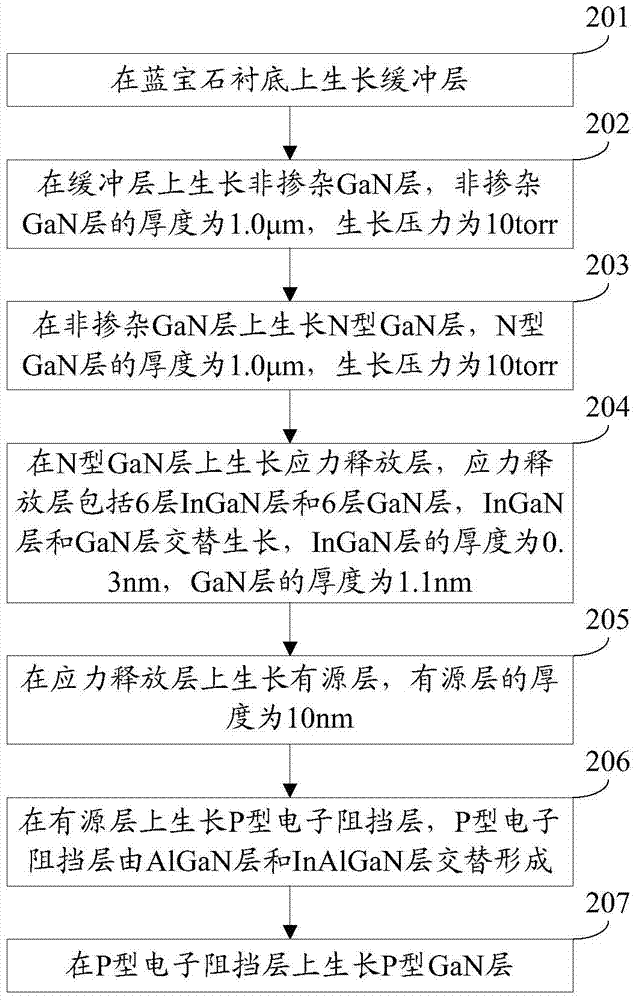

[0068] An embodiment of the present invention provides a method for manufacturing a light-emitting diode epitaxial wafer. This embodiment is a specific implementation of the method for manufacturing a light-emitting diode epitaxial wafer provided in Embodiment 1. Refer to figure 2 , the manufacturing method includes:

[0069] Step 201: growing a buffer layer on a sapphire substrate.

[0070] Step 202: growing a non-doped GaN layer on the buffer layer, the thickness of the non-doped GaN layer is 1.0 μm, and the growth pressure is 10 torr.

[0071] Specifically, the growth rate of the non-doped GaN layer is 2.0 μm / h, and when growing the non-doped GaN layer, the growth rate of the non-doped GaN layer remains unchanged. The flow rate of the Ga source is 200-500 sccm, and when the non-doped GaN layer is grown, the flow rate of the Ga source gradually increases.

[0072] Step 203: growing an N-type GaN layer on the non-doped GaN layer, the thickness of the N-type GaN layer is 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com