Diamond growth tray and system

A diamond and tray technology, which is applied in the field of diamond growth trays and systems, can solve problems such as high local plasma density, and achieve the effects of low product stress, growth inhibition, and growth rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

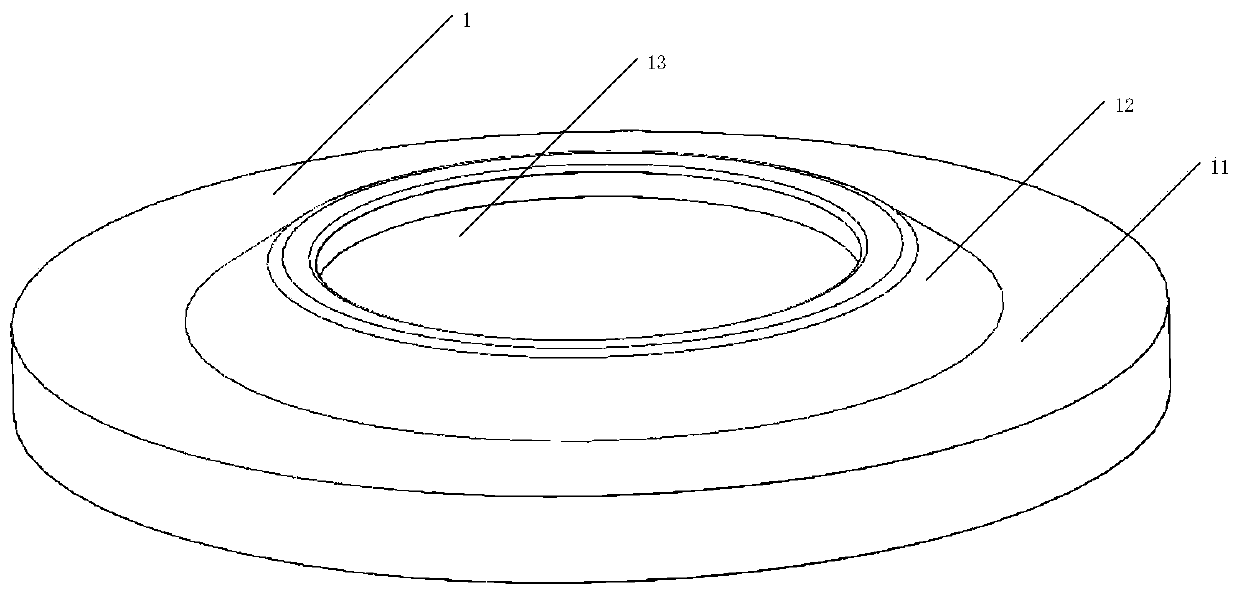

[0035] Please focus on figure 1 , the present invention provides a diamond growth tray, comprising a base 11 and a platform 12 installed on the base 11;

[0036] The platform 12 is in the shape of a regular polygonal prism or a truncated cone, and has a groove 13 on the upper surface, and the edge of the opening of the groove 13 is designed to be chamfered.

[0037] Specifically, during the diamond growth process, the seed crystal is placed inside the groove 13, and the height of the upper surface of the seed crystal is 1-2mm lower than the edge of the concave edge; the diameter of the groove 13 is based on the synthetic single crystal The effective growth area is determined, and the diameter is less than or equal to 155mm; before use, the bottom of the groove 13 is first placed with auxiliary heat dissipation materials, such as filaments, sheets, etc., and the filament sheets are high temperature resistant (that is, can withstand over 1400°C) material, such as molybdenum, ni...

Embodiment 2

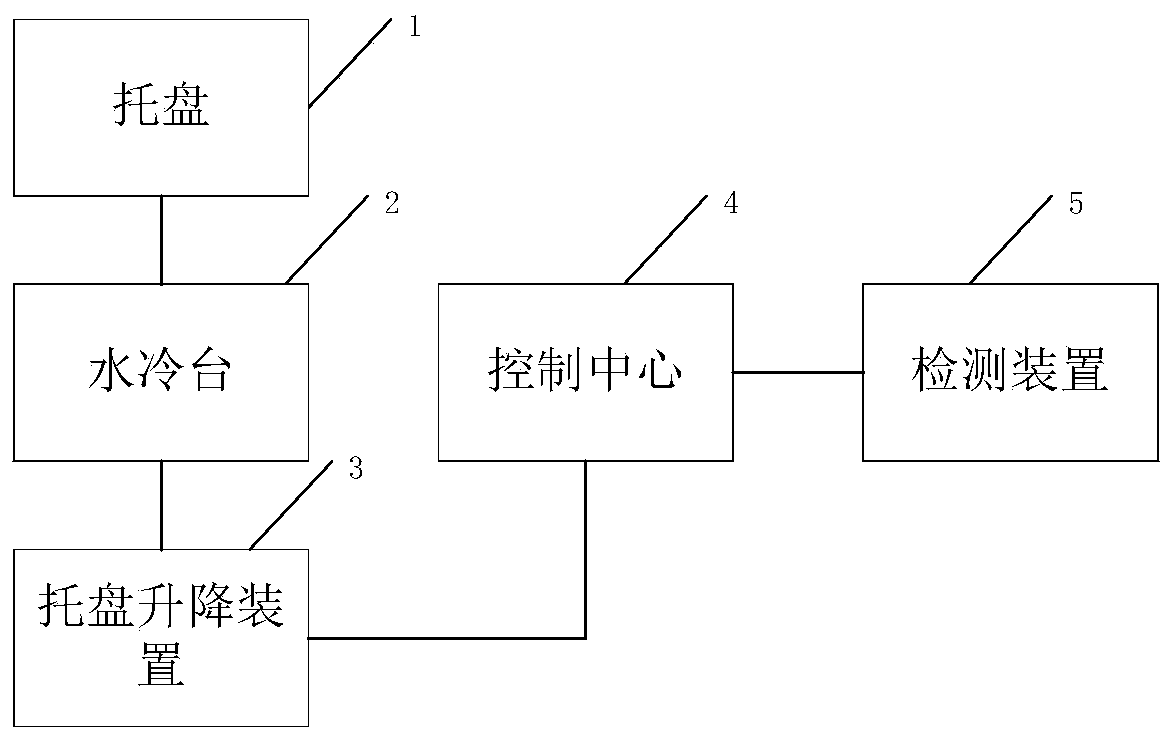

[0047] Please focus on figure 2 , the present invention also provides a diamond growth system, including the tray 1, and also includes a water cooling table 2, a tray lifting device 3, a detection device 5, and a control center 4;

[0048] The tray 1 is fixed on the water cooling table 2;

[0049] The water cooling platform 2 is installed on the tray lifting device 3;

[0050] The pallet lifting device 3 is used to control the up and down movement of the pallet 1; specifically, the pallet lifting device 3 includes a pulse motor and a lifting rail, and the water cooling table 2 is installed on the lifting rail to ensure that each time The lifting height is controlled between 0.1-1mm;

[0051] The detection device 5 is used to detect the thickness of the diamond in real time during the diamond growth process, and transmit the thickness data to the control center 4; the detection device 5 is a proximity position sensor;

[0052] The control center 4 is used to control the ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com