Atomized culture device for vegetables

A technology for cultivating devices and vegetables, applied in the field of agricultural machinery, which can solve the problems of destroying the ratio of nutrient solution, affecting the normal use of the device, and unfavorable absorption of nutrient solution by the roots of plants, so as to meet the space conditions and light conditions and reduce the content of harmful components , is conducive to the effect of respiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0056] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

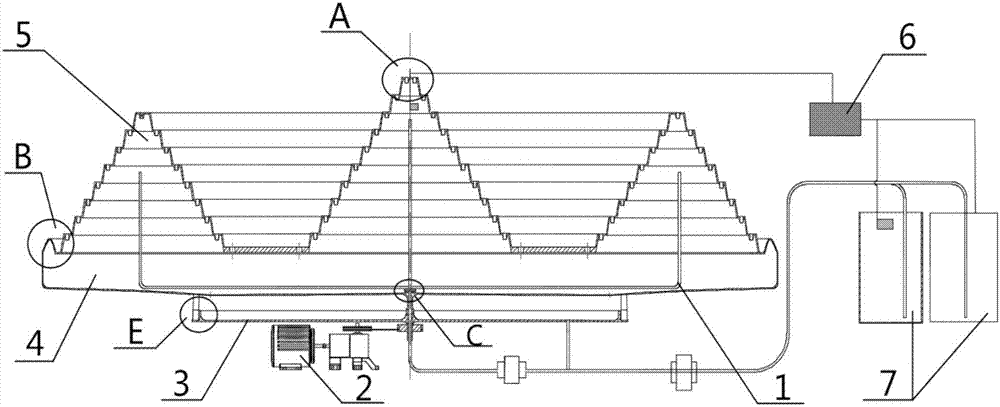

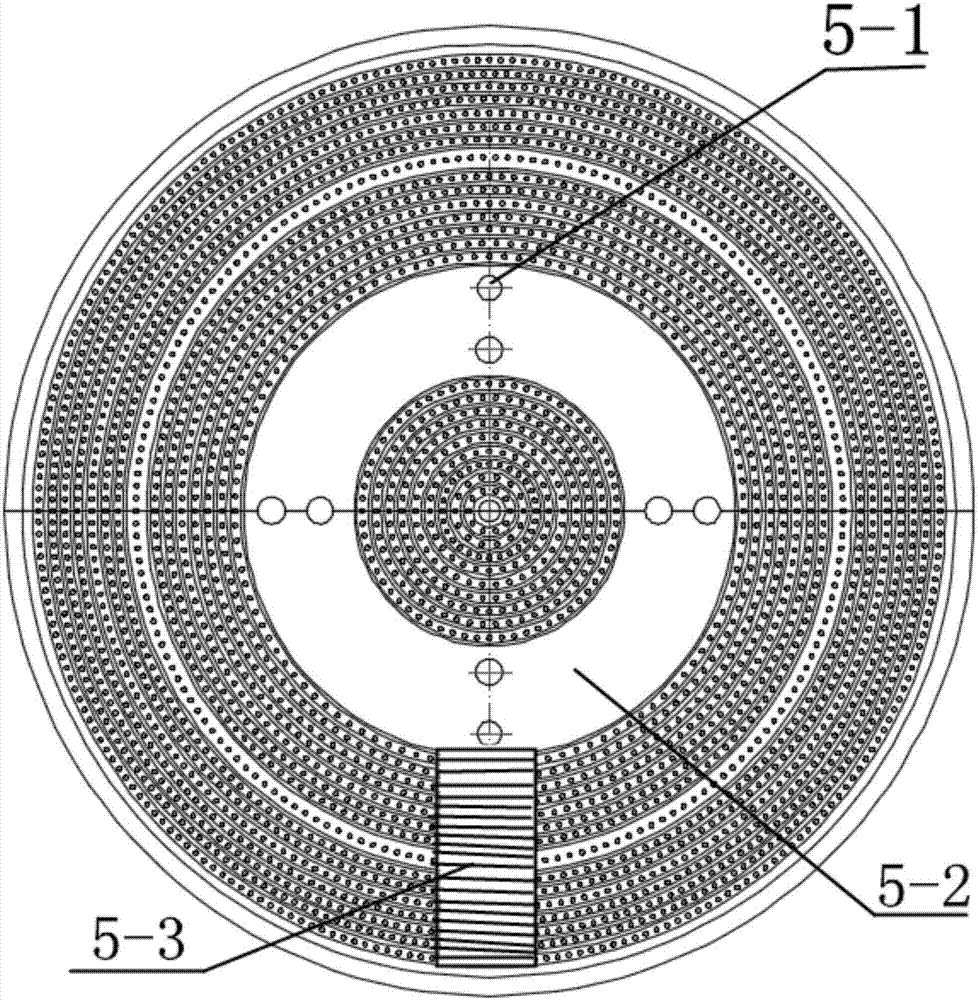

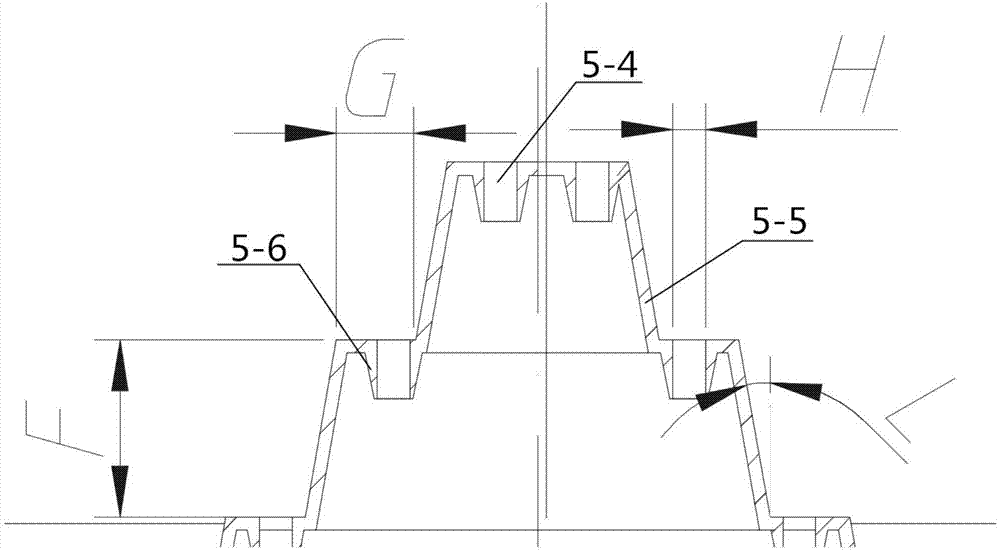

[0057] Such as figure 1 and figure 2 As shown, the present invention discloses a vegetable atomization cultivation device, in which a dynamically rotating conical shell is used as a planting step. The vegetable atomization cultivation device of the present invention is composed of a spraying part 1 , a driving and transmission mechanism 2 , a base 3 , a nutrient solution recovery mechanism 4 , a planting step 5 , a monitoring system 6 and a nutrient solution tank 7 .

[0058] The prime mover and transmission mechanism 2 are fixedly installed on the fixed platform by fixing bolts, and the fixed bolts can be ordinary bolts of M16; 2. The first pulley 2-3, the belt 2-4 and the shaft coupling 2-5 are composed; the motor 2-1 provides the driving force for the operation of the at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com