Method for preparing nano-structure single crystal silver

A nanostructure and single crystal technology, applied in the direction of single crystal growth, nanotechnology, single crystal growth, etc., can solve the problems of low yield, complicated preparation process, single silver single crystal morphology, etc., and achieve high yield and high purity The effect of high, green synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare an ammonia solution with a mass fraction of 20%, soak the activated carbon in it for 10 minutes, take it out and dry it at 60°C; prepare a silver-ammonia solution with a concentration of 0.0001mol / L, put the pretreated activated carbon in it, and dry it at room temperature for 1 minute Finally, granular nanostructure single crystal silver grows on the surface of activated carbon. Wherein the conductivity of the activated carbon is 200S / m, and the chloride ion content is 0.01wt%.

Embodiment 2

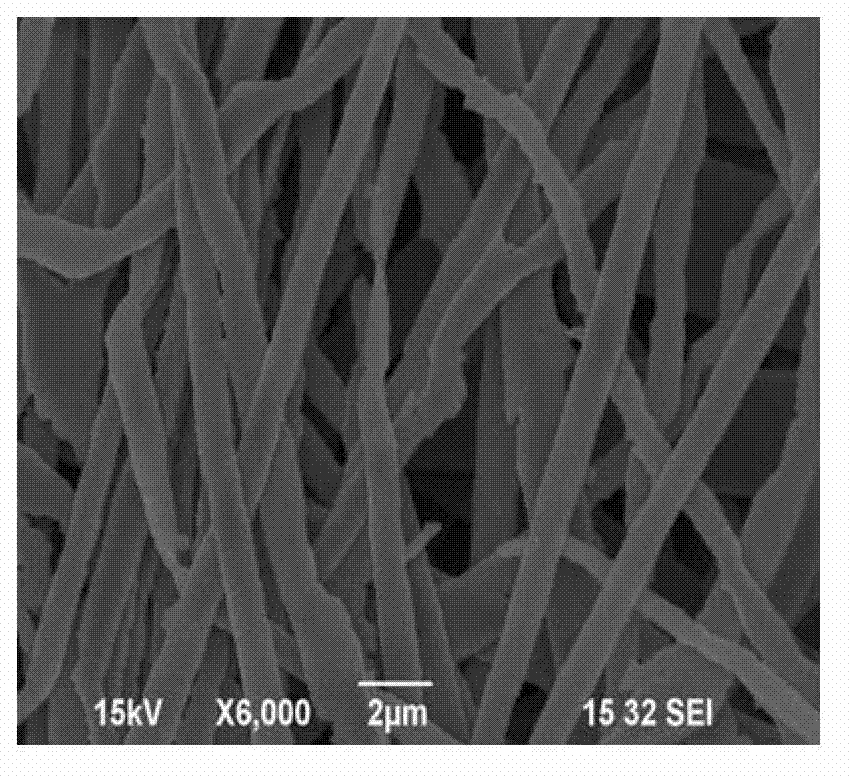

[0031] Prepare an ammonia solution with a mass fraction of 5%, soak the activated carbon in it for 30 minutes, take it out and dry it at 80°C; prepare a silver-ammonia solution with a concentration of 0.005mol / L, put the pretreated activated carbon in it, and dry it at room temperature for 1 hour Afterwards, ribbon-shaped nanostructured single crystal silver was grown on the surface of activated carbon, and the scanning electron microscope photos are as follows: figure 1 As shown, the diffraction spot picture of transmission electron microscope is as follows image 3 shown. Wherein the conductivity of the activated carbon is 600S / m, and the chloride ion content is 0.05wt%.

Embodiment 3

[0033] Prepare an ammonia solution with a mass fraction of 10%, soak the activated carbon in it for 1 hour, take it out and dry it at 100°C; prepare a silver-ammonia solution with a concentration of 0.01mol / L, put the pretreated activated carbon in it, and dry it at room temperature for 40 minutes Afterwards, single crystal silver with zigzag nanostructure grows on the surface of activated carbon. Wherein the conductivity of the activated carbon is 800 S / m, and the chloride ion content is 0.08wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com