A three-dimensional multi-layer planting device

A planting device, three-dimensional multi-layer technology, applied in the field of three-dimensional multi-layer planting devices, can solve the problems of poor resistance to extreme weather in greenhouses, low degree of automation of greenhouses, low utilization rate of space, etc., so as to reduce economic losses, reduce losses, Good effect against pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

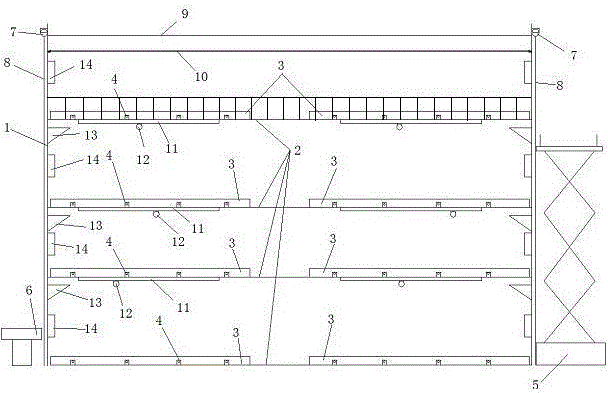

[0030] figure 1 A three-dimensional multi-layer planting device is shown, including a greenhouse support 1, a height adjustment plate 2, a soil laying frame 3, a sprinkler nozzle 4, an electric roller shutter mechanism, a lifting platform 5 and a console 6, and the greenhouse support 1 is vertical It is arranged on a horizontal plane, and more than two height adjustment plates 2 are arranged horizontally along the vertical direction of the greenhouse support 1. The soil laying frame 3 is arranged on the upper bottom surface of the height adjustment plate 2, and the soil laying frame 3 is provided with sprinkler nozzles. 4;

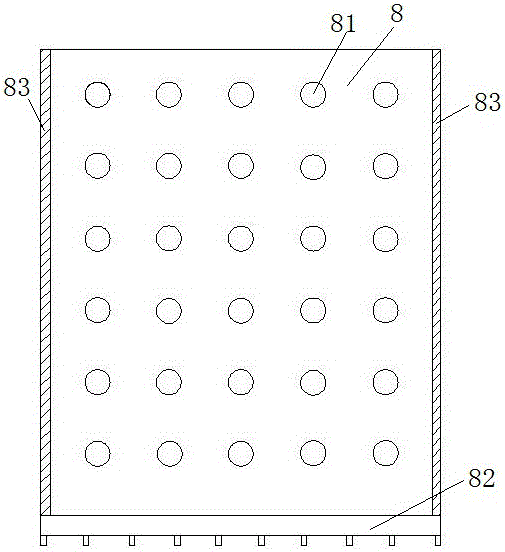

[0031]The electric roller shutter mechanism includes a tubular motor, a roller shutter tube 7 and a roller shutter 8. The roller shutter tube 7 is arranged on the upper part of the greenhouse support 1 along the boundary of the greenhouse support 1 and parallel to the horizontal plane. The roller shutter tube 7 is located at the height adjustment plate 2. ...

specific Embodiment 2

[0034] In this embodiment, a sunshade is added on the basis of the specific embodiment 1. The top of the greenhouse support 1 is provided with a sunshade, and the sunshade is located above the height adjustment plate 2. The sunshade includes a rainproof layer 9 and a dimming net. 10. The rainproof layer 9 is fixed on the top of the greenhouse support 1, and the dimming net 10 has more than two layers, and is hung under the rainproof layer 9 through the hooks arranged on the upper part of the greenhouse support 1.

[0035] The purpose of setting the sunshade on the upper part of the greenhouse support 1 is to adjust the light transmittance in the greenhouse according to the needs of the growth of the crops. If the soil humidity is too high, the probability of root rot of the crops will be increased. In order to make the growth environment of the crops more stable, use The rainproof layer 9 is used to block rainwater, and what the rainproof layer 9 uses is a plastic film, which c...

specific Embodiment 3

[0037] In this embodiment, an electric slide rail 11 and an LED plant supplementary light 12 are added on the basis of the specific embodiment 1. The lower bottom surface of the height adjustment plate 2 is also provided with an electric slide rail 11 and an LED plant supplementary light 12. The electric slide rail 11 is fixed on the lower bottom surface of the height adjustment plate 2, and is parallel to the horizontal plane. The LED plant fill light 12 is erected on the electric slide rail 11, and the electric slide rail 11 and the LED plant fill light 12 are connected to the console 6 for electric connect.

[0038] An electric slide rail 11 is set on the bottom surface of the height adjustment plate 2, and the LED plant supplementary light 12 is erected on the electric slide rail 11. Setting the LED plant supplementary light 12 can increase the illumination of the lower crops according to the demand, and the electric slide rail 11 can move the LED plant supplementary light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com