LED chip structure efficiently matched with ZnO thin film and manufacturing method of LED chip structure

An LED chip and manufacturing method technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of difficulty in manufacturing ZnO devices, difficult P-type doping, poor ESD, etc., and achieve improved light extraction rate and good contact performance. , Improve the effect of high voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

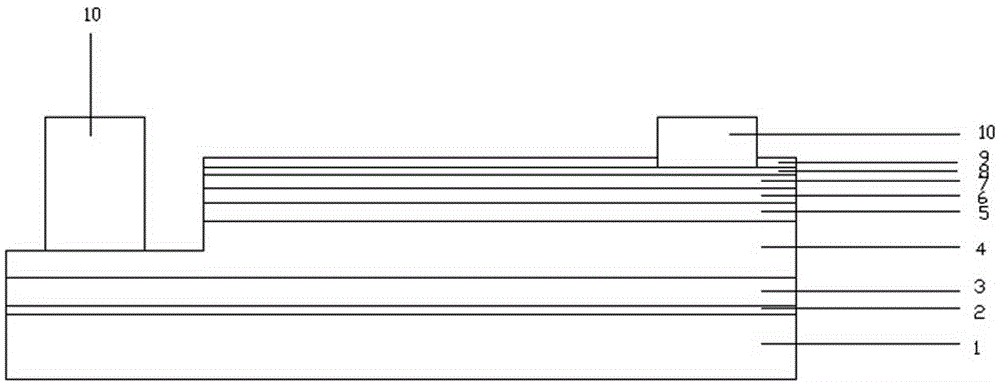

[0021] like figure 1 As shown, the LED chip structure provided by the present invention is efficiently matched with the ZnO thin film, including a substrate 1 and an epitaxial layer formed on the substrate 1, and the epitaxial layer includes a buffer layer 2 grown sequentially, an intrinsic GaN layer 3, Si-doped n-type GaN layer 4, light-emitting multiple quantum well structure 5, electron blocking layer 6, Mg-doped p-type GaN layer 7, contact layer 8 and ZnO transparent conductive layer 9, wherein the buffer layer 2 is GaN Or the AlN buffer layer 2, the n-type GaN layer 4 is provided with an N-type electrode 10, and the Mg-doped P-type GaN layer 7 is provided with a P-type electrode 10.

[0022] During specific implementation, the difference between different embodiments of the present invention mainly lies in the difference of the contact laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com