Silver nanowire composite transparent conductive film and preparation method thereof

A transparent conductive film, silver nanowire technology, applied in the direction of equipment for manufacturing conductive/semiconductive layer, cable/conductor manufacturing, conductive layer on insulating carrier, etc., can solve the problem of short life and film resistivity. The level of the ITO film and the inability of the substrate material to form good adhesion can improve the conductivity and oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

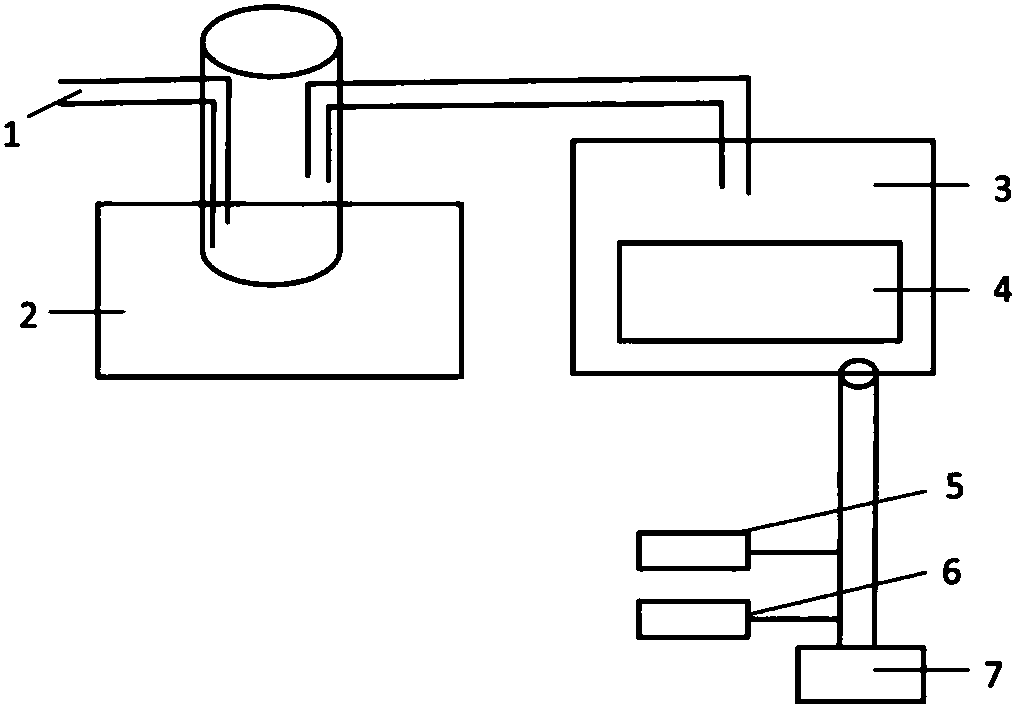

Image

Examples

Embodiment 1

[0025] (1) Glass substrate processing

[0026] Choose ultra-clear glass with a diameter of 10mm as the substrate, and use acetone, ethanol, and deionized water to ultrasonicate for 30 minutes, and then clean it with deionized water; use nitrogen to dry the substrate, and dry it in a blast oven at 120°C;

[0027] (2) Preparation of silver nanowire solution

[0028] Utilize ethylene glycol as solvent to reduce silver nitrate by polyalcohol thermal method, obtain silver nanowire solution 30ml, centrifuge separates silver nanowire (0.2g) and solvent, after removing solvent, silver nanowire is dissolved in isopropanol solution , be mixed with the silver nanowire ethanol dispersion liquid of 5mg / ml, five minutes ultrasonic treatment, obtain the silver nanowire solution (concentration 5mg / ml, volume 40ml) of stable dispersion;

[0029] (3) Preparation of silver nanowire film

[0030] The silver nanowire film is prepared by the pulling method, and the silver nanowire film is prepare...

Embodiment 2

[0034] (1) Glass substrate processing

[0035] Choose ultra-clear glass with a diameter of 20mm as the substrate, and use acetone, ethanol, and deionized water to sonicate for 30 minutes, and then clean it with deionized water; use nitrogen to dry the substrate, and dry it in a blast oven at 120°C;

[0036] (2) Preparation of silver nanowire solution

[0037] Utilize ethylene glycol as the polyalcohol thermal reduction silver nitrate of solvent, obtain silver nanowire solution 60ml, centrifuge separates silver nanowire (0.4g) and solvent, after removing solvent, silver nanowire is dissolved in ethanol solution, prepares into a silver nanowire ethanol dispersion of 10 mg / ml, and ultrasonically treat it for five minutes to obtain a stably dispersed silver nanowire solution;

[0038] (3) Preparation of silver nanowire film

[0039] The silver nanowire film is prepared by the pulling method, and the silver nanowire film is prepared by multiple pulling. After the silver nanowire fi...

Embodiment 3

[0043] (1) Glass substrate treatment: choose ultra-clear glass with a diameter of 20mm as the substrate, use acetone, ethanol, and deionized water to ultrasonicate for 30 minutes, and then clean it with deionized water; use nitrogen to dry the substrate, and dry it in a blast drying oven at 120°C Dry; (2) Preparation of silver nanowire solution

[0044] Utilize ethylene glycol as the polyhydric alcohol heat reduction silver nitrate of solvent, obtain silver nanowire solution 90ml, centrifuge separates silver nanowire (0.6g) and solvent, after removing solvent, silver nanowire is dissolved in ethanol and water by pressing A mixed solution with a volume ratio of 8:2 was prepared into a 4 mg / ml ethanol dispersion of silver nanowires, and subjected to ultrasonic treatment for five minutes to obtain a stable dispersed silver nanowire solution.

[0045] (3) Preparation of silver nanowire film

[0046] The silver nanowire film is prepared by the pulling method, and the silver nanowi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com