LED epitaxial structure with high hole injection efficiency

A technology of injection efficiency and epitaxial structure, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of low hole concentration, achieve the effect of increasing hole concentration, improving hole mobility, and reducing electron overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

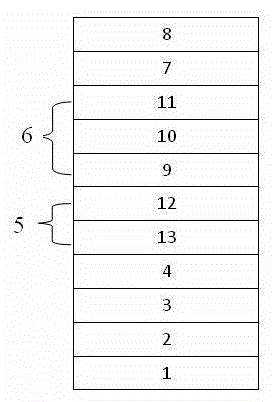

[0017] (1) The sapphire substrate 1 is subjected to a high-temperature cleaning treatment at 1000° C. for 10 minutes, and then a nitriding treatment is performed.

[0018] (2) Lower the temperature to 500° C., grow a GaN buffer layer 2 with a thickness of 100 angstroms and a pressure of 300 Torr.

[0019] (3) Without trimethylgallium (TMGa), raise the temperature to 1000°C, anneal the GaN buffer layer 2 for 3 minutes, and then pass through TMGa to grow the undoped GaN layer 3 with a thickness of 1 μm, pressure It is 300 Torr.

[0020] (4) Disilane is introduced at a temperature of 1000° C. to grow an N-type GaN layer 4 with a thickness of 2 μm and a pressure of 100 Torr.

[0021] (5) After the growth of the N-type GaN layer 4 is completed, the multi-quantum well 5 is grown, and the multi-quantum well 5 is composed of the InGaN layer 13 and the GaN layer 12 . The growth temperature of the GaN layer 12 is 800°C and the thickness is 100 angstroms, the growth temperature of the ...

Embodiment 2

[0027] (1) The sapphire substrate 1 is subjected to a high-temperature cleaning treatment at 1100° C. for 20 minutes, and then a nitriding treatment is performed.

[0028] (2) Lower the temperature to 600° C., grow a GaN buffer layer 2 with a thickness of 200 angstroms and a pressure of 450 Torr.

[0029] (3) Without trimethylgallium (TMGa), the temperature was raised to 1100°C, and the GaN buffer layer 2 was annealed for 4 minutes, and then TMGa was injected to grow the undoped GaN layer 3 with a thickness of 1.5 μm. The pressure is 400 Torr.

[0030] (4) Disilane is introduced at a temperature of 1100° C. to grow an N-type GaN layer 4 with a thickness of 3 μm and a pressure of 200 Torr.

[0031] (5) After the growth of the N-type GaN layer 4 is completed, the multi-quantum well 5 is grown, and the multi-quantum well 5 is composed of the InGaN layer 13 and the GaN layer 12 . The growth temperature of the GaN layer 12 is 850°C and the thickness is 110 angstroms, the growth t...

Embodiment 3

[0037] (1) The sapphire substrate 1 is subjected to a high-temperature cleaning treatment at 1200° C. for 30 minutes, and then to a nitriding treatment.

[0038] (2) Lower the temperature to 700° C., grow a GaN buffer layer 2 with a thickness of 300 angstroms and a pressure of 600 Torr.

[0039] (3) Without trimethylgallium (TMGa), raise the temperature to 1200°C, anneal the GaN buffer layer 2 for 5 minutes, and then pass through TMGa to grow the undoped GaN layer 3 with a thickness of 2 μm and pressure It is 500 Torr.

[0040] (4) Disilane is injected at a temperature of 1200° C. to grow an N-type GaN layer 4 with a thickness of 4 μm and a pressure of 300 Torr.

[0041] (5) After the growth of the N-type GaN layer 4 is completed, the multi-quantum well 5 is grown, and the multi-quantum well 5 is composed of the InGaN layer 13 and the GaN layer 12 . The growth temperature of the GaN layer 12 is 900°C and the thickness is 120 angstroms; the growth temperature of the InGaN lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com