Unintentionally doped high resistance GaN film with InGaN insertion layer and preparation method thereof

An interlayer, unintentional technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficulty in taking into account high resistivity and high crystal quality, achieve no memory effect, and strong controllability of growth parameters , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

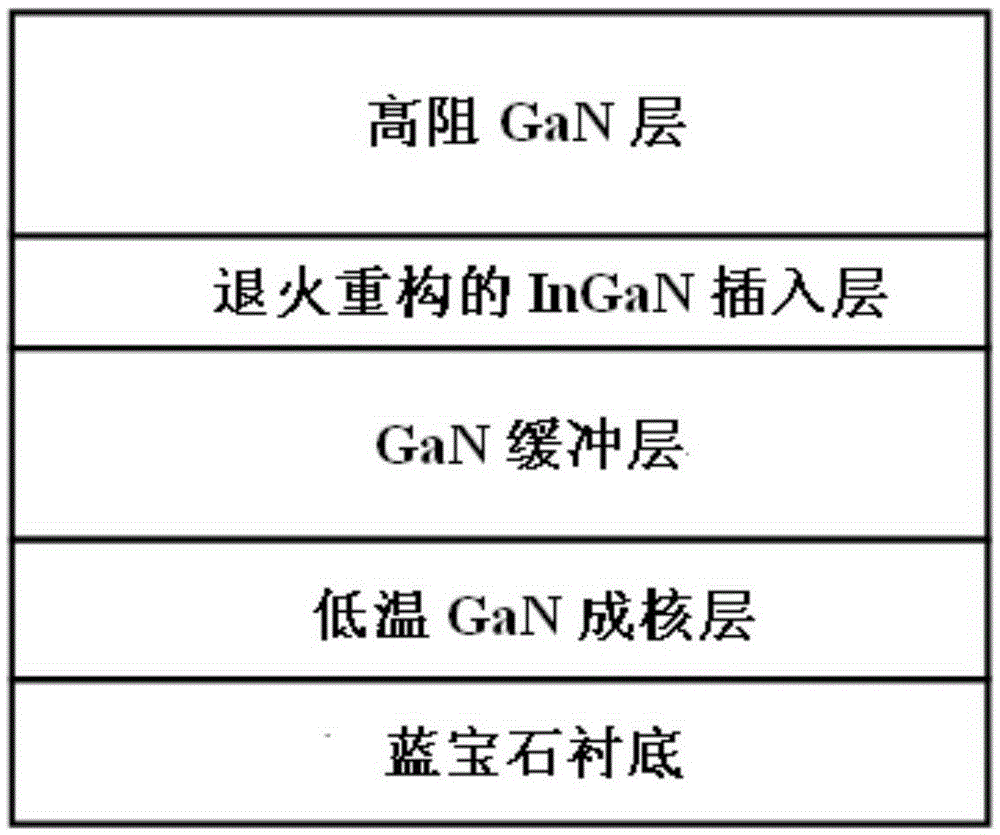

[0035] Such as figure 1 As shown, this embodiment provides an unintentionally doped high-resistance GaN film with an InGaN insertion layer, including:

[0036] - substrate, the material of which is sapphire;

[0037] - a low-temperature GaN nucleation layer, which is fabricated on the substrate, wherein the thickness of the low-temperature GaN nucleation layer is 25nm;

[0038] —GaN buffer layer, which is made on the low-temperature GaN nucleation layer, with a growth temperature of 1045°C and a thickness of 3.2 μm;

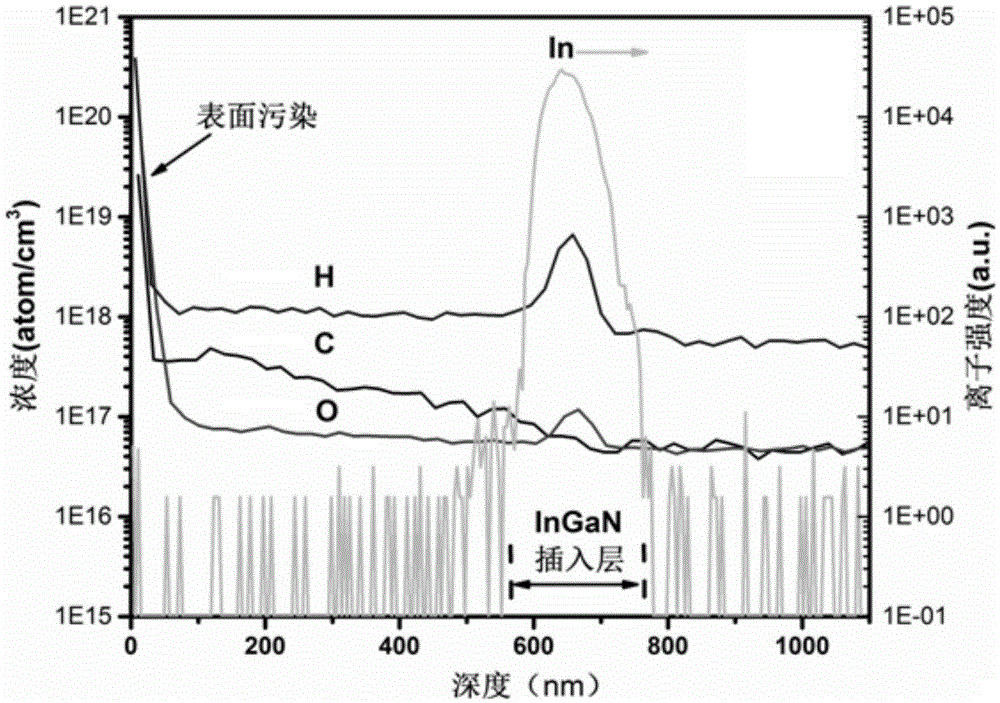

[0039] —Annealed and reconstructed InGaN insertion layer, which is fabricated on the GaN buffer layer, with a thickness of about 65nm; the growth temperature of the InGaN insertion layer is 770°C, and after the growth is completed, the temperature is raised to 1050°C for high-temperature annealing for 600s.

[0040] - A high-resistance GaN layer, which is fabricated on the annealed and reconstructed InGaN insertion layer, with a growth temperature of 1050° C. a...

Embodiment 2

[0052] This embodiment discloses an unintentionally doped high-resistance GaN film with an InGaN insertion layer. By introducing an InGaN insertion layer and annealing at a high temperature, an appropriate amount of edge dislocations, and a small amount of screw dislocations, using edge dislocations to induce carbon acceptors in the reaction chamber to incorporate into the GaN film, and then compensate the background electrons to achieve a high-resistance GaN film.

[0053] Specifically, the unintentionally doped high-resistance GaN thin film with an InGaN insertion layer includes: a sapphire layer, a low-temperature GaN nucleation layer, a GaN buffer layer, an annealed and reconstructed InGaN insertion layer, a high barrier GaN layer. The thickness of the low-temperature GaN nucleation layer is 30 nm, the thickness of the GaN buffer layer is 2 μm; the thickness of the annealed and reconstructed InGaN insertion layer is 100 nm, and the thickness of the high resistance GaN laye...

Embodiment 3

[0063] This embodiment discloses an unintentionally doped high-resistance GaN thin film with an InGaN insertion layer, including: an unintentional doped high-resistance GaN thin film with an InGaN insertion layer, including substrates arranged in sequence from bottom to top Bottom, low temperature GaN nucleation layer, GaN buffer layer, annealed and reconstructed InGaN insertion layer, high resistance GaN layer. The thickness of the low-temperature GaN nucleation layer is 30 nm; the thickness of the GaN buffer layer is 4 μm; the thickness of the annealed and reconstructed InGaN insertion layer is 90 nm; the thickness of the high resistance GaN layer is 1.5 μm.

[0064] The method for preparing an unintentionally doped high-resistance GaN film with an InGaN insertion layer in this embodiment includes the following steps:

[0065] Step 1: placing the substrate in a reaction chamber for heat treatment;

[0066] Step 2: using a two-step growth method to grow a low-temperature GaN...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com