LED of novel quantum well structure and method for manufacturing LED

A manufacturing method, quantum well technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of difficult to obtain free hole concentration and mobility epitaxial wafers, hole injection and transport obstacles, low mobility of effective mass, etc. problem, to achieve the effect of weakening the efficientdroop effect, increasing the luminous power, and increasing the probability of matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

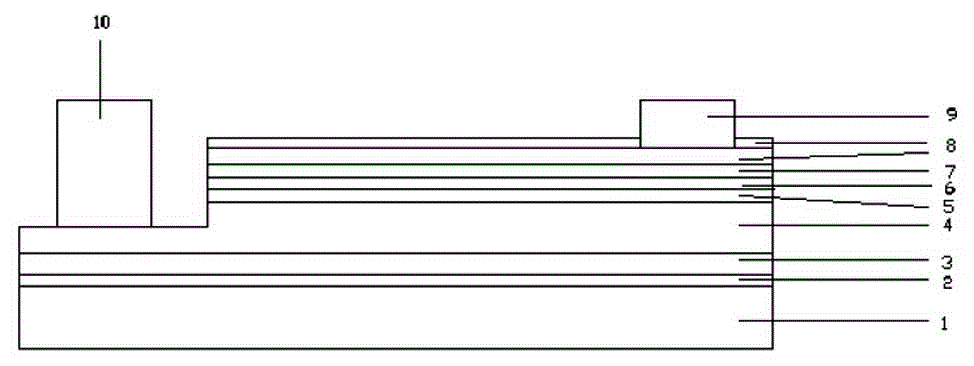

[0026] Embodiment 1: quantum well structure such as figure 2 As shown, there are seven barriers and six wells co-grown in the thickness direction from left to right. The first and second quantum wells both have an inner slope structure and are graded composition quantum wells. The third, fourth, and Both the fifth and sixth quantum wells have internal step structures, which are step-type component quantum wells.

Embodiment 2

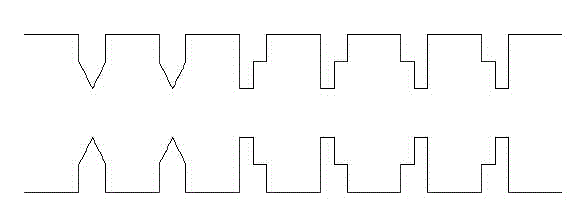

[0027] Embodiment 2: quantum well structure such as image 3 As shown, on the basis of Example 1, the barriers of the first, second and third quantum wells all have outwardly convex structures, which are convex group barriers, and the fourth, fifth and sixth quantum wells All have an inward concave structure, which is a barrier for concave groups.

Embodiment 3

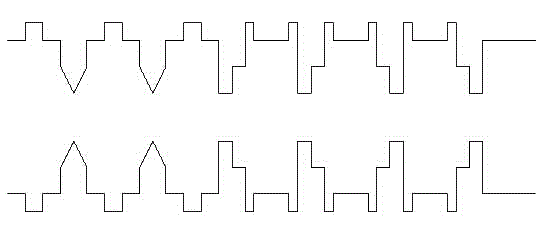

[0028] Embodiment 3: quantum well structure such as Figure 4 As shown, there are seven barriers and six wells co-grown in the thickness direction from left to right, and the first, second, third, and fourth quantum wells all have inner slope structures, which are graded composition quantum wells. The fifth and sixth quantum wells are all thin inner step structures, which are δ-type component quantum wells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com