LED epitaxial structure with warpage adjusting structure layer and growth method thereof

A technology for adjusting structure and epitaxial structure, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as the inability to effectively adjust the warpage degree of epitaxial wafers and affect the performance of LED products, so as to improve the uniformity of growth conditions and improve yield. , improve the effect of parameter uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

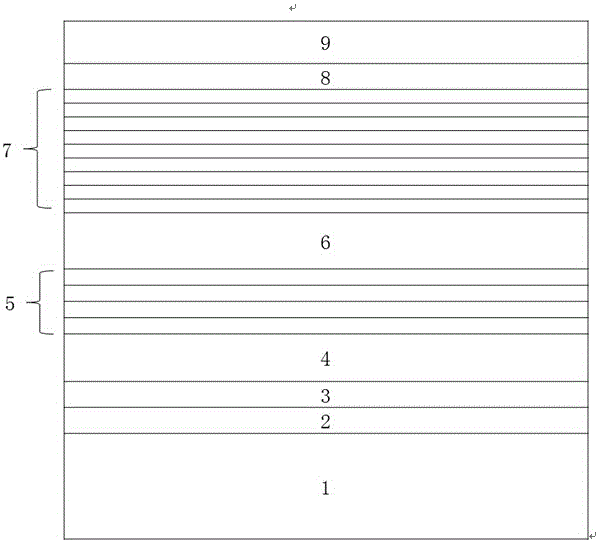

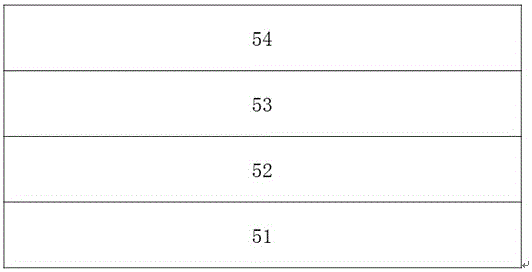

[0033] Such as figure 1 As shown, the present invention has an LED epitaxial structure with a warpage-adjusting structural layer, which includes a sapphire substrate 1, a nucleation layer 2, a roughening layer 3, a high-temperature GaN layer 4, a warpage-adjusting structural layer 5, and a high-temperature The N-type GaN layer 6 , the light emitting layer 7 , the P-type AlGaN layer 8 and the P-type GaN layer 9 , and the warp adjustment structure layer 5 is arranged between the high-temperature GaN layer 4 and the high-temperature N-type GaN layer 6 . Such as figure 2 As shown, the warpage adjustment structure layer 5 is Si 3 N 4 The superlattice layer of the layer 51, the first GaN layer 52, the AlGaN layer 53 and the second GaN layer 54 has a period number of 1-40 and a single period thickness of 31-1930nm.

[0034] The growth temperature of the warpage regulating structure layer 5 is 700-1200° C., and the growth pressure is 50-300 torr, wherein Si 3 N 4 layer and AlGaN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com