Method for directly and conformally covering graphene film on full surface of substrate with three-dimensional structure

A graphene film and three-dimensional structure technology, applied in the field of materials, can solve the problems of high production cost, long production cycle, surface adsorption pollution, etc., and achieve the effects of simple operation, short production cycle and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for conformally covering the entire surface of a graphene film directly on a three-dimensional structure substrate, comprising the following steps:

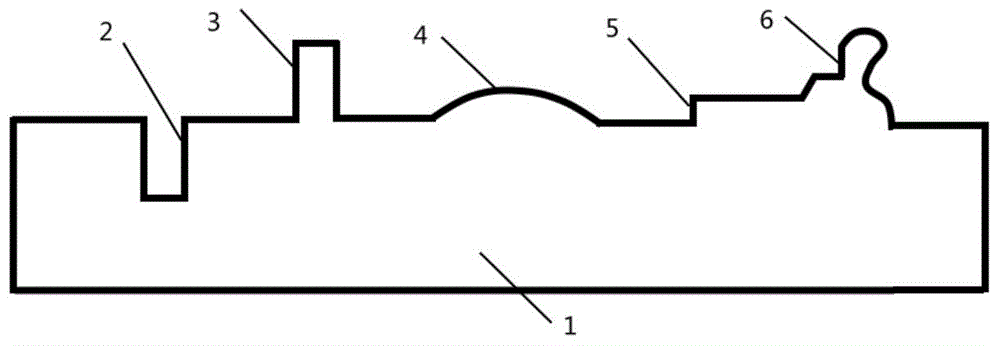

[0025] A. will have a three-dimensional surface structure (such as figure 1 The silicon wafers with the spherical structure shown in ) were ultrasonically cleaned in acetone, 95vol% ethanol, and pure water for 2 minutes respectively, and dried with nitrogen;

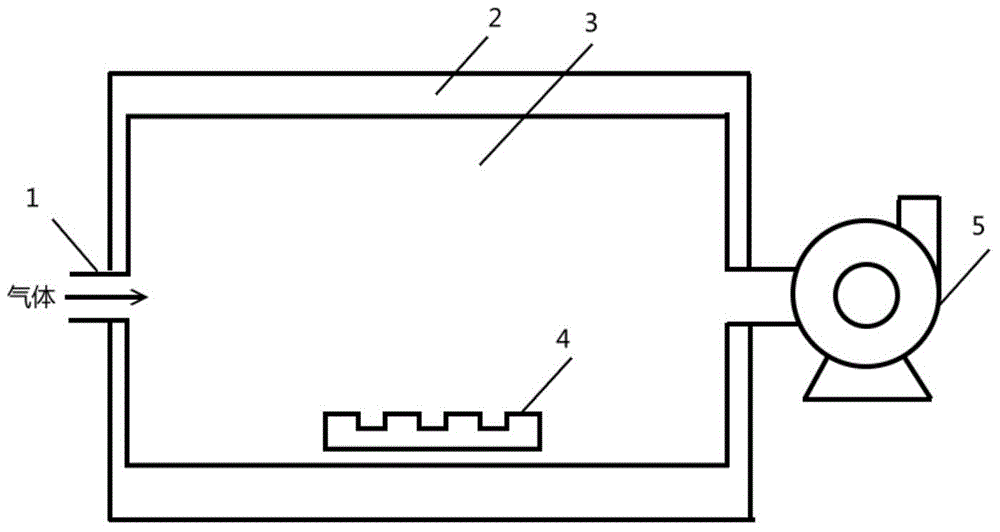

[0026] B. putting the silicon chip after step A drying is in the tube type CVD system vacuum chamber of 50mm (such as figure 2 shown), seal the vacuum chamber; pump the sealed vacuum chamber to 1Pa with a vacuum pump, fill the vacuum chamber with argon gas to 1atm, and then pump it to 1Pa with a vacuum pump, and repeat the operation three times to make the air in the vacuum chamber exhausted, and then fill the vacuum chamber with hydrogen, maintaining the air pressure at 5×10 3 Pa;

[0027] C. Raise the temperature of the vacuum chamber filled with hydro...

Embodiment 2

[0030] A method for conformally covering the entire surface of a graphene film directly on a three-dimensional structure substrate, comprising the following steps:

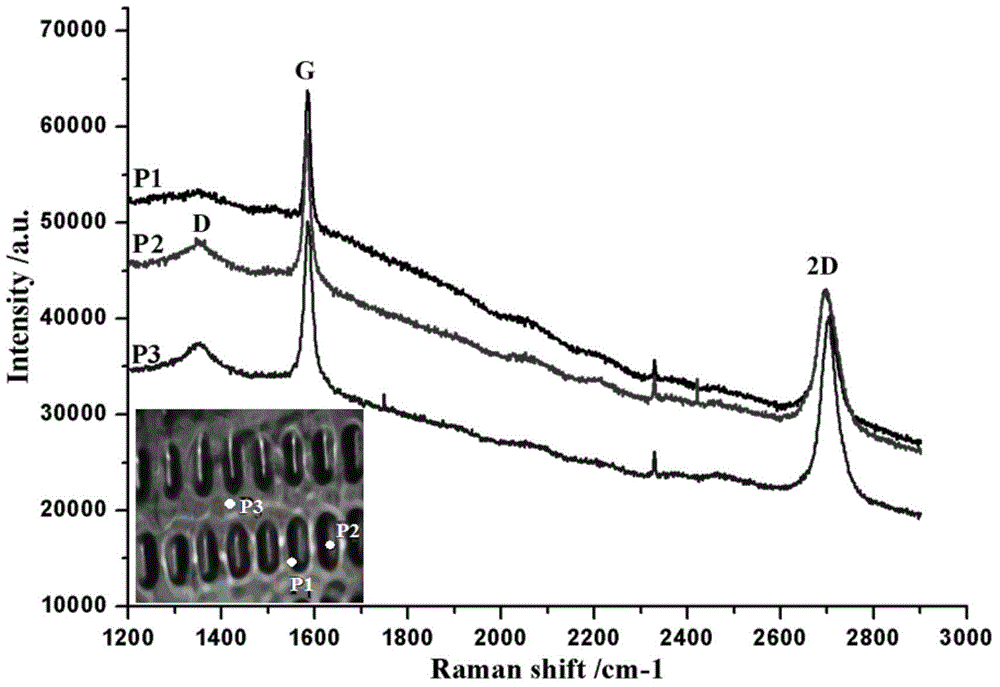

[0031] A. A copper sheet with a periodic surface structure (such as image 3 The substrate with the three-dimensional structure shown in ) was placed in acetone, 95vol% ethanol, and pure water for 2 minutes, and then dried with nitrogen;

[0032] B. the copper sheet after step A drying is put pipe diameter in the tube type CVD system vacuum chamber of 50mm (as figure 2 shown), seal the vacuum chamber; pump the sealed vacuum chamber to 1Pa with a vacuum pump, fill the vacuum chamber with argon gas to 1atm, and then pump it to 1Pa with a vacuum pump, and repeat the operation three times to make the air in the vacuum chamber exhausted, and then fill the vacuum chamber with hydrogen, maintaining the air pressure at 1×10 3 Pa;

[0033] C. Raise the temperature of the vacuum chamber filled with hydrogen in step B to...

Embodiment 3

[0036] A method for conformally covering the entire surface of a graphene film directly on a three-dimensional structure substrate, comprising the following steps:

[0037] A. will have a three-dimensional surface structure (such as figure 1The microporous structure shown in ) germanium slices were placed in acetone, 95vol% ethanol, and pure water for 2 minutes, and then dried with nitrogen;

[0038] B. the germanium sheet after the drying of step A is put in the tube type CVD system vacuum chamber of 50mm (such as figure 2 shown), seal the vacuum chamber; pump the sealed vacuum chamber to 2Pa with a vacuum pump, fill the vacuum chamber with argon to 1 atm, and then pump it to 2Pa with a vacuum pump, and repeat the operation three times to make the air in the vacuum chamber Exhaust, then fill the vacuum cavity with hydrogen, and maintain the air pressure at 150Pa;

[0039] C. The temperature of the vacuum chamber filled with hydrogen in step B is raised to 780° C., 10 sccm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com