Growth method for reducing density of micro-tubes in large-sized high-quality SiC single crystal

A growth method and high-quality technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of new microtube generation, low density of single crystal microtubes, etc., and achieve the effect of reducing the total number of microtubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

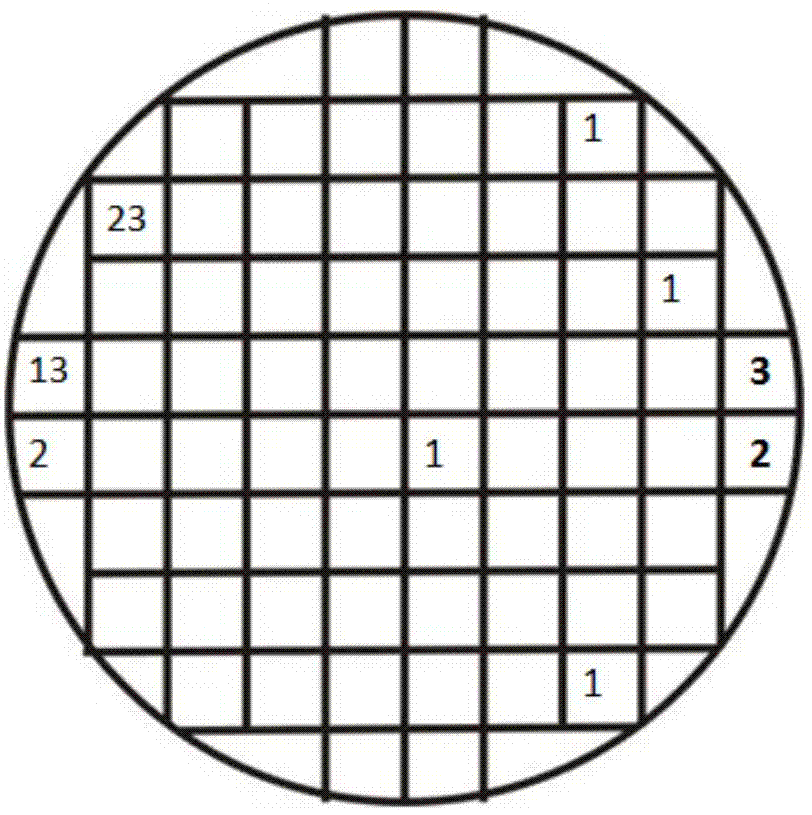

[0031] In the SiC single crystal furnace, the SiC single crystal is grown by the sublimation method, and the size of the grown single crystal is 3 inches by induction heating. The SiC powder is placed in the lower part of the graphite crucible, the SiC seed crystal is placed in the upper part of the crucible, and a certain distance is kept between the SiC seed crystal and the SiC powder.

[0032] Before growth, first vacuum to remove impurities, so that the vacuum degree of the growth chamber reaches 10 -4 Pa. The size of the seed plane used is 3 inches, the growth plane is a carbon plane, and the growth direction is along the c-axis [0001] direction. The micropipe defect density of the seed crystal is 4.5 / cm 2 . During growth, the growth pressure was 5 mbar, the temperature of the upper cover of the crucible was 2100 °C, the nucleation rate was controlled at 10 μm / h, and the temperature gradient in the axial direction was controlled at 50 °C / mm. After 20 h of growth, high...

Embodiment 2

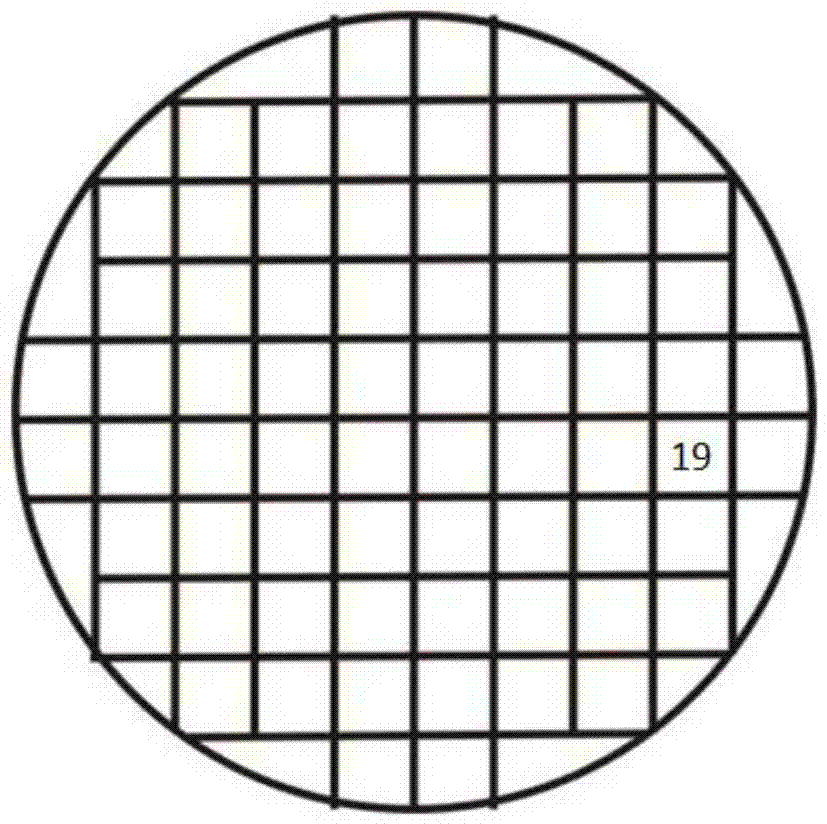

[0039] A method for reducing the density of micropipes in high-quality SiC crystals, as described in Example 1, the difference is that before growth, the vacuum is evacuated until the vacuum degree reaches 10 -3 Pa. During growth, the growth pressure is 50 mbar, the temperature of the crucible cover is 2400 °C, the nucleation rate is controlled at 500 μm / h, and the temperature gradient in the axial direction is controlled at 200 °C / mm. After 22 hours of growth, high-purity nitrogen gas was introduced into the growth chamber for 2 hours at a flow rate of 5 sccm. The growth time is 60h, and after the growth, the cooling rate is 40°C / h. After three generations of cyclic growth, the result was the same as in Example 1.

Embodiment 3

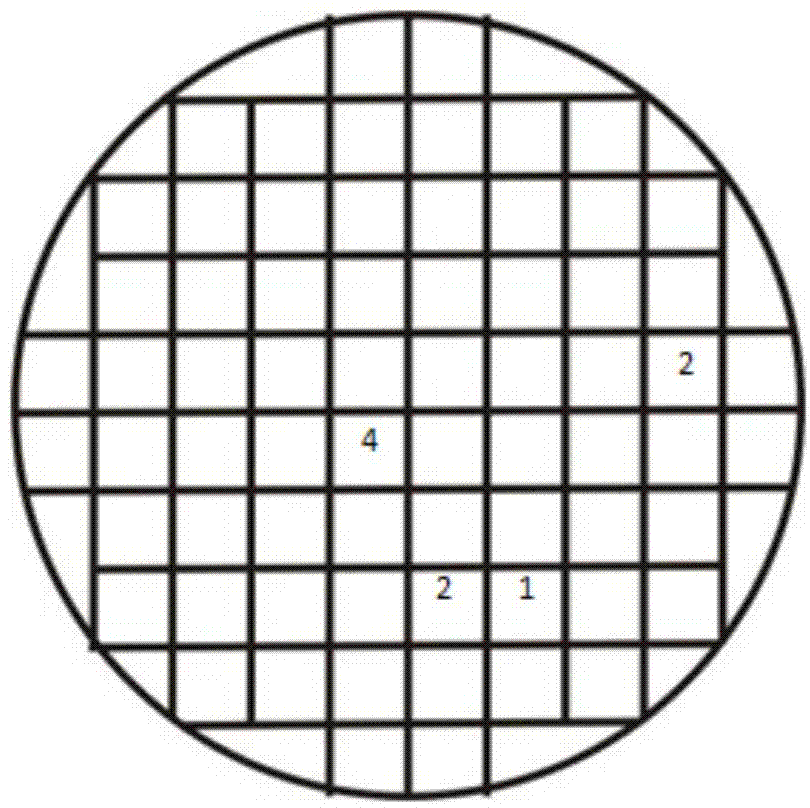

[0041] A method for reducing the density of micropipes in high-quality SiC crystals, the specific method is the same as in Example 1, the difference is that before the growth, the vacuum is evacuated until the vacuum degree reaches 10 -2 Pa. During growth, the growth pressure was 45 mbar, the temperature of the upper cover of the crucible was 2200 °C, the nucleation rate was controlled at 220 μm / h, and the temperature gradient in the axial direction was controlled at 150 °C / mm. After growing for 24 hours, high-purity nitrogen gas was passed through the growth chamber for 10 hours at a flow rate of 10 sccm. The growth time is 100h, and after the growth, the cooling rate is 100°C / h. After three generations of cyclic growth, the result was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com