Manufacturing method of multilayer printed board embedded resistor

A technology of multi-layer printed boards and embedded resistors, applied in directions including printed resistors, multi-layer circuit manufacturing, and printed electrical components, etc. problems, to achieve the effect of neat graphics edges, uniform thickness, and improved production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further explained below in conjunction with embodiment. But the scope of protection of this patent is not limited to the specific implementation.

[0030] Implementation example

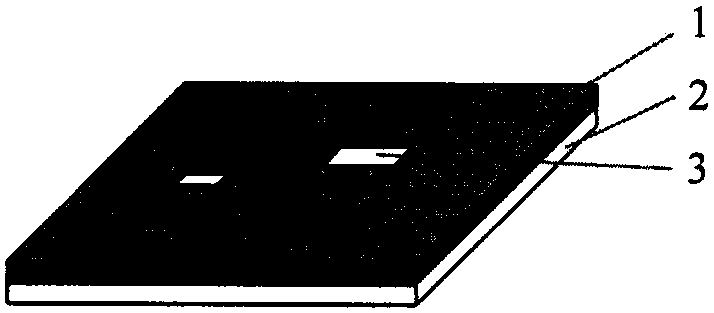

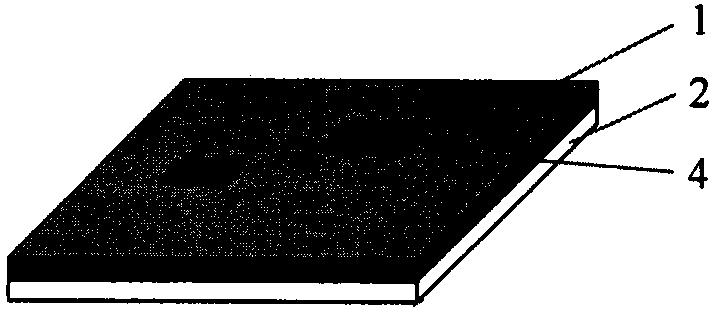

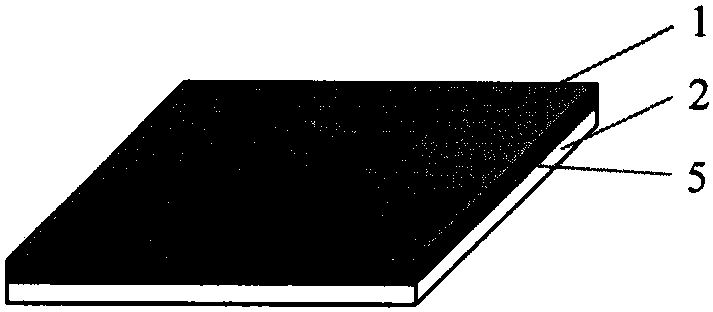

[0031] The multilayer printed board with embedded resistors produced in this example is a 4-layer printed board with dimensions 100mm×150mm×1.6mm embedded with 100 resistors with a resistance value of 2.8KΩ. The resistors are embedded in the second layer of the multilayer printed board. Before the inner layer board is processed to make the inner layer circuit, the embedded resistor is made on the inner layer board. It is necessary to etch and remove the copper foil embedded in the resistance part of the inner layer board, and then print the resistance paste with the required square resistance value on this part according to the design requirements, and then complete the embedded resistance after pre-baking, mechanical brushing and post-curing. Then, according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com