Preparation method of magnesium oxide/polystyrene composite dielectric material

A technology of polystyrene and dielectric materials, applied in the direction of magnesium oxide, etc., can solve the problems of low dielectric constant and limited application, and achieve the effects of improved dielectric properties, low filling volume, and improved comprehensive dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

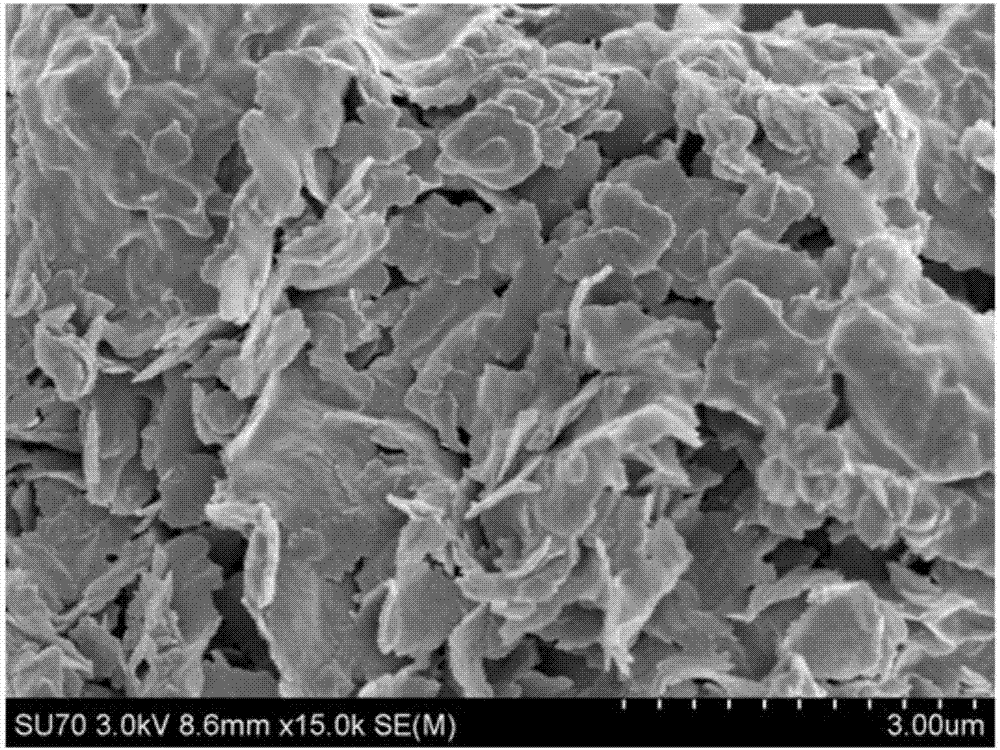

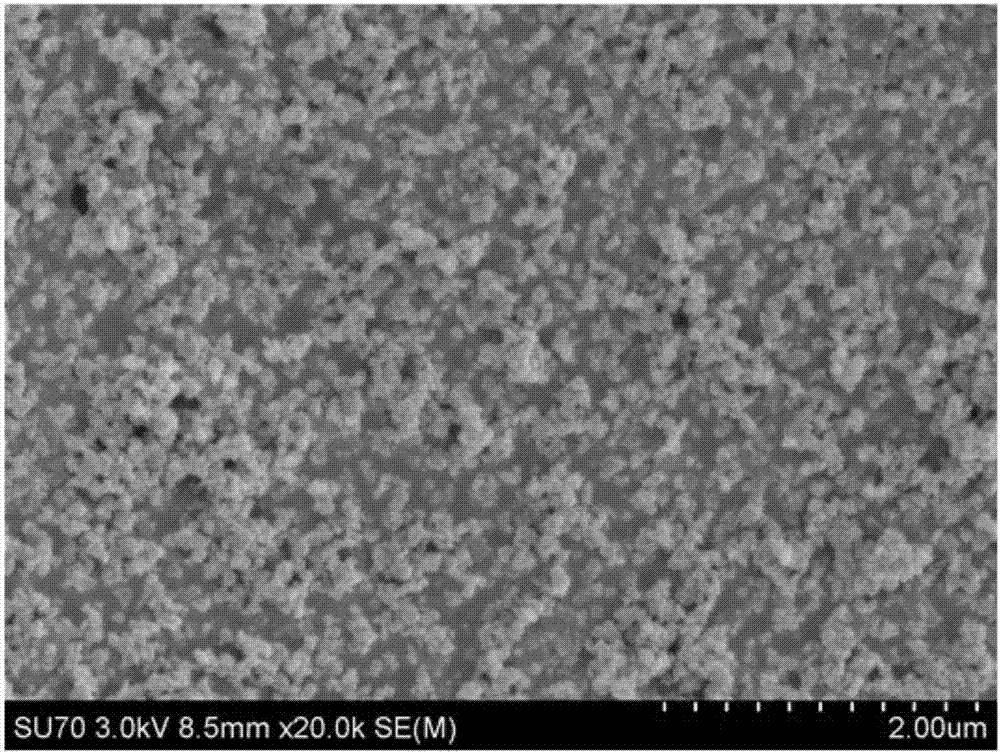

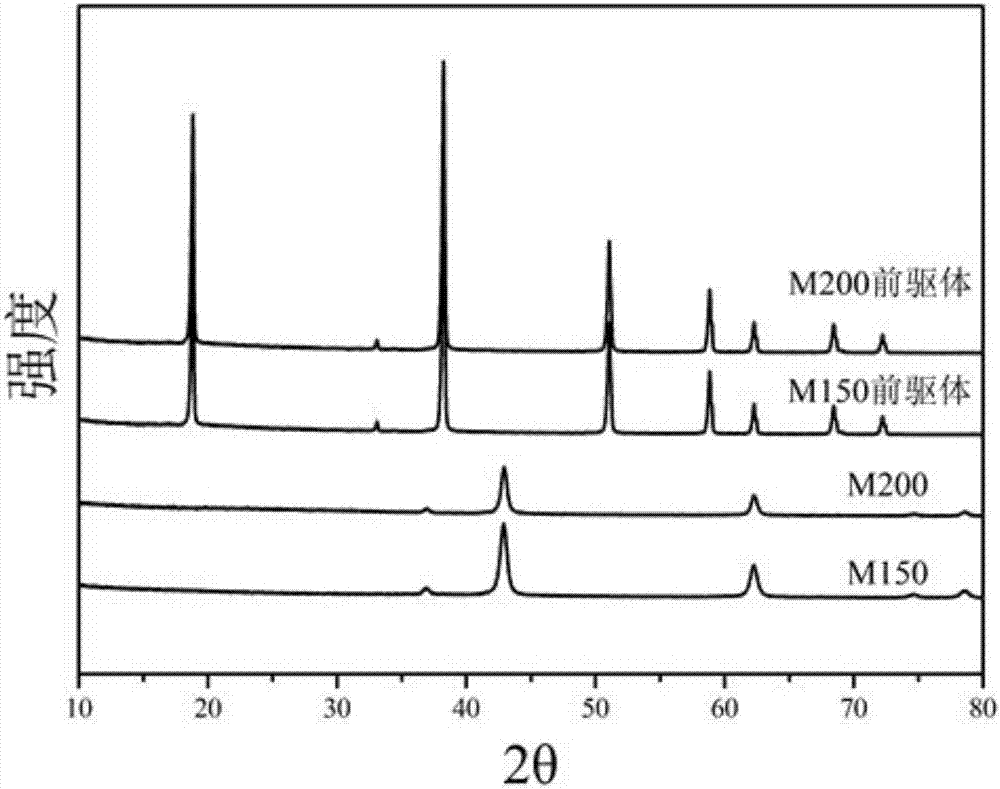

[0032] (1) In the three-necked flask filled with ethylene glycol, add magnesium acetate tetrahydrate and polyvinylpyrrolidone, the mass ratio of magnesium acetate tetrahydrate and polyvinylpyrrolidone is 1: 100; the three-necked flask is moved to the heater, and Connect the condensing reflux device, feed condensed water; control the reaction temperature at 180-185°C, react for two hours, and cool to room temperature naturally.

[0033] When adding reactants, control the mass ratio of magnesium acetate tetrahydrate and ethylene glycol to be 1: 29 to prepare flaky magnesium oxide (number M150, in flake shape); or, control the quality of magnesium acetate tetrahydrate and ethylene glycol The ratio is 1:39 to prepare granular magnesium oxide (code M200, in granular form).

[0034] (2) The turbid liquid obtained from the reaction was centrifuged, and the white precipitate was washed alternately with deionized water and ethanol for 2 rounds, then moved to an oven, and dried at a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com