Rubber, preparation method thereof, rubber composition and vulcanized rubber

A technology of rubber composition and rubber glue, which is applied in the field of rubber, can solve the problems of limited addition of silica, poor dispersion of silica, and poor mechanical properties, and achieve excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The rubber preparation method provided by the present invention includes adding white carbon black into the obtained rubber glue solution and mixing uniformly during the rubber preparation process, and then removing the solvent in the glue solution.

[0020] The present invention has no special limitation on the type of the rubber glue, such as various existing rubber glues, for example, it can be solution polystyrene butadiene rubber glue, solution polybutadiene rubber glue, solution polyisoamyl At least one of diene rubber glue and soluble polystyrene thermoplastic elastomer glue, preferably solution polystyrene butadiene rubber glue.

[0021] The rubber glue can be obtained commercially, or can be prepared according to various methods known to those skilled in the art. According to a specific embodiment of the present invention, the rubber glue is prepared according to the following method: in the presence of an initiator, the olefin monomer is polymerized in a solve...

preparation example 1

[0039] This preparation example is used to illustrate the rubber provided by the present invention and its preparation method.

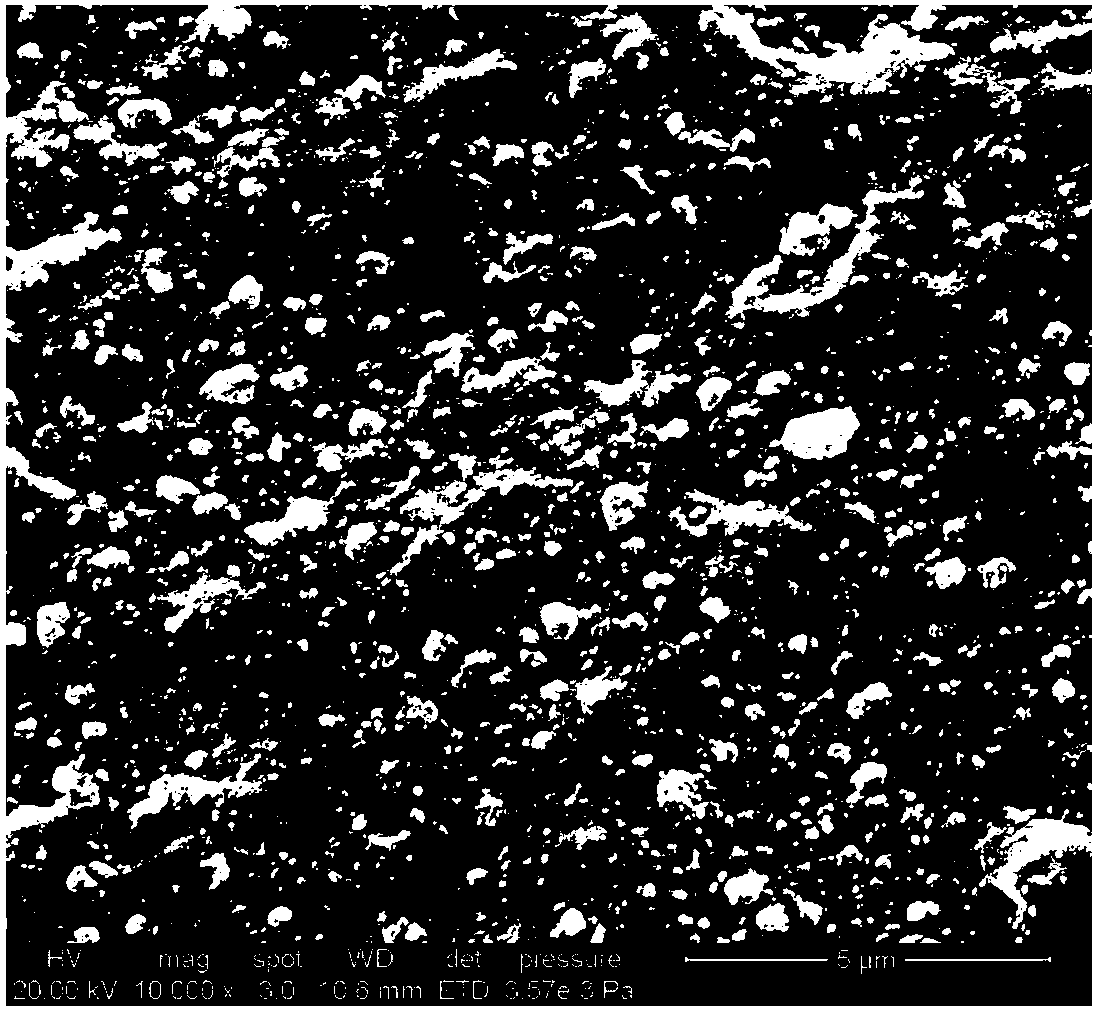

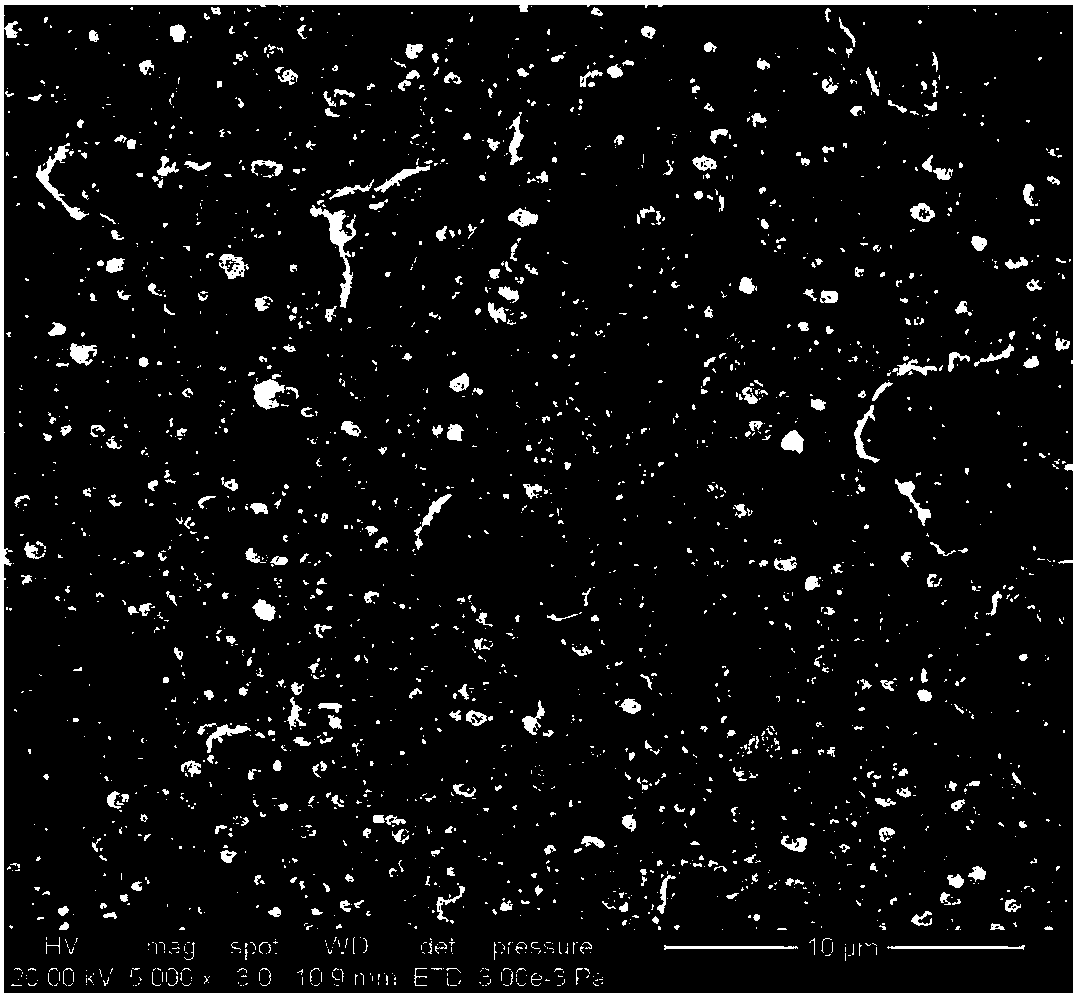

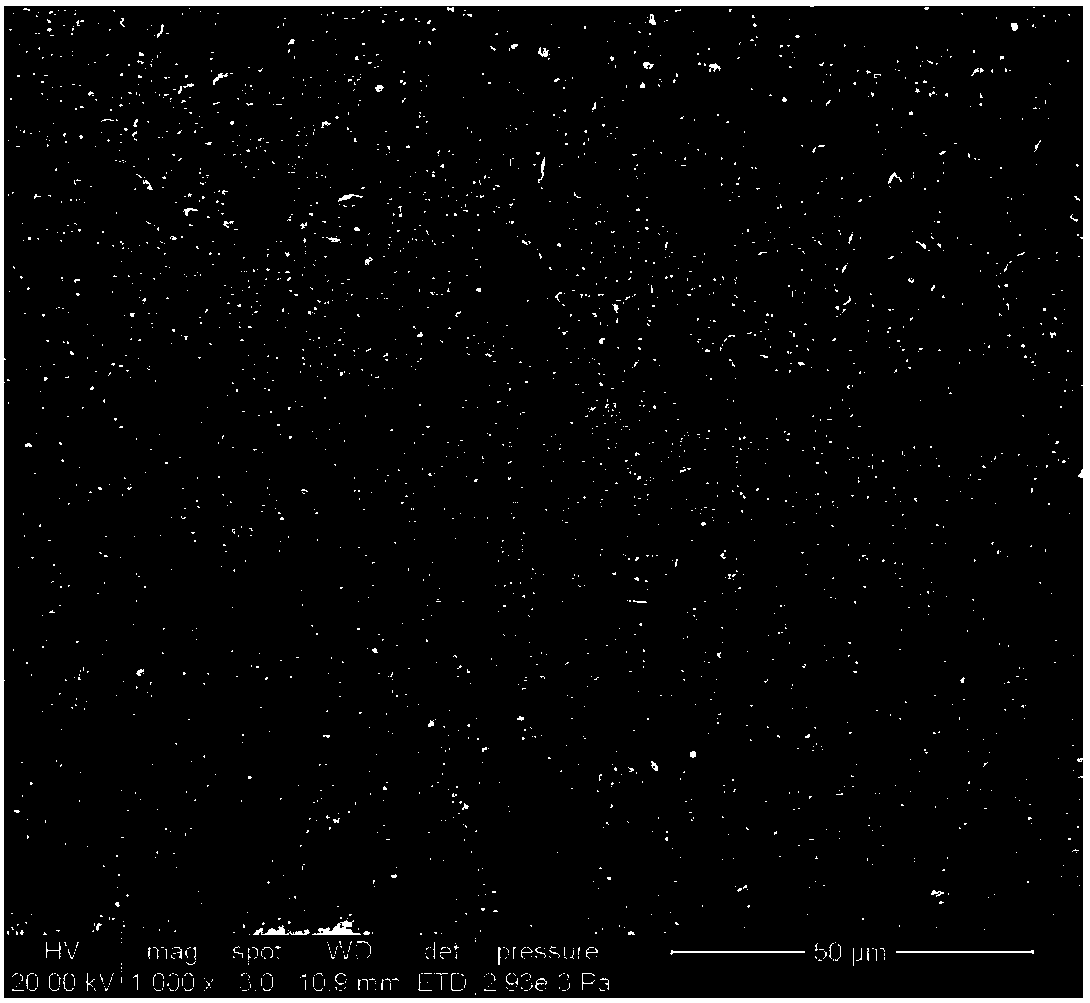

[0040] The mass fraction that 5kg is taken from the solution polymerization butadiene-styrene rubber production device is the oil-extended polystyrene-butadiene rubber glue SSBR2535E of 10% by weight (the solvent wherein is the mixture of normal hexane and hexanaphthene, is industrial grade, the weight ratio of n-hexane to cyclohexane is 85:15, and its performance index is shown in Table 1, the same below) into a 50L enamel stirred tank and kept stirring, wherein, the temperature inside the enamel stirred tank is 50°C, and the stirring rate 300rpm. Add 1 kg of n-hexane at room temperature to a 20L enamel stirring tank, and gradually add 300g of white carbon black. After all the white carbon black is added, start stirring and stir at room temperature and 300rpm for 5 minutes, and then use a pipeline grinder to grind for 10 minutes to obtain white carb...

preparation example 2

[0042] This preparation example is used to illustrate the rubber provided by the present invention and its preparation method.

[0043] Add 5 kg of oil-extended soluble polystyrene-butadiene rubber glue SSBR2535E with a mass fraction of 10% by weight taken from the solution polymerization butadiene-styrene rubber production device into a 50L enamel stirring tank and keep stirring, wherein, in the enamel stirring tank The temperature was 60°C and the stirring rate was 200 rpm. Add 1 kg of n-hexane at room temperature into a 20L enamel stirring kettle, gradually add 400g of white carbon black, and after all the white carbon black is added, start stirring and stir at room temperature and 200rpm for 10 minutes, and then use a pipeline grinder to grind for 10 minutes to obtain A dispersion liquid having a silica content of 28.57% by weight and a silica particle diameter D90 of 6.8 μm. Then turn on the bottom switch of the 20L enamel stirring tank under the condition of starting st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com