High-temperature-resistant adhesive for lithium ion battery and battery pole piece applying the adhesive

A high-temperature-resistant adhesive and battery pole piece technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor dispersion of water-based adhesives and affect the electrochemical performance of batteries, and achieve good adhesion , Improve the cycle performance at room temperature and shorten the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

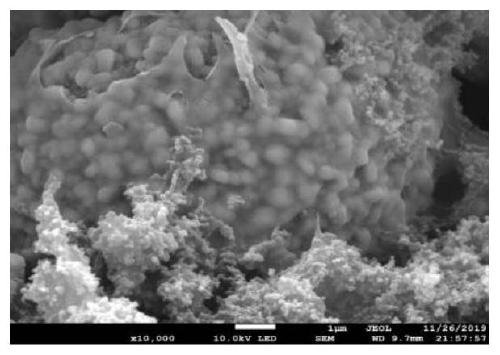

[0036] Weigh PMDA 3.63g, ODA 2.64g, BAHPP 0.85g with a molar ratio of 10:8:2, add all ODA and BAHPP into 30ml DMF solvent, stir mechanically, wait until ODA and BAHPP are all dissolved in DMF, then bath in ice water Under the condition of, PMDA was added twice, each time adding 50% of the total mass of PMDA to obtain a polyamic acid solution with a solid content of 20%, and the polyamic acid solution was formulated into a glue solution with a solid content of 10%. Mix the positive electrode active material NCM811, conductive carbon black, and polyamic acid according to the mass parts of 80%, 10%, and 10%. Add NMP solvent to dissolve the mixture. The volume ratio of the polyamic acid solution to the solvent is 1.2:1. Stir for 20 minutes , The positive electrode slurry was prepared. The polyimide slurry containing functional groups -OH was coated on aluminum foil and dried at room temperature for 12 hours, and then subjected to heat treatment. The heat treatment process is to inc...

Embodiment 2

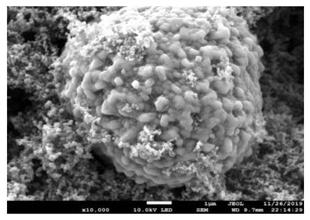

[0040] Weigh PMDA3.54g, ODA1.92g, BAHPP1.93g with a molar ratio of 10:6:4, add all ODA and BAHPP into 30ml DMF solvent, stir mechanically, wait until ODA and DABA are all dissolved in DMF, then bath in ice water Under the condition of, PMDA was added twice, each time adding 50% of the total mass of PMDA to obtain a polyamic acid solution with a solid content of 20%, and the polyamic acid solution was formulated into a glue solution with a solid content of 10%. Mix the positive electrode active material NCM811, conductive carbon black, and polyamic acid according to the mass parts of 80%, 10%, and 10%. Add NMP solvent to dissolve the mixture. The volume ratio of the polyamic acid solution to the solvent is 1.2:1. Stir for 20 minutes , The positive electrode slurry was prepared. The polyimide slurry containing the functional group -COOH was coated on aluminum foil and dried at room temperature for 12 hours, and then subjected to heat treatment. The heat treatment process was to i...

Embodiment 3

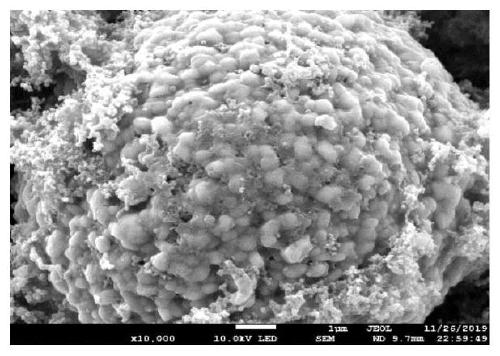

[0043] Weigh PMDA 3.45g, ODA 1.25g, BAHPP 2.42g with a molar ratio of 10:4:6, add all ODA and BAHPP into 30ml DMF solvent, stir mechanically, and after all PDA and DADHBP are dissolved in DMF, take an ice-water bath Under the condition of, PMDA was added twice, each time adding 50% of the total mass of PMDA to obtain a polyamic acid solution with a solid content of 20%, and the polyamic acid solution was formulated into a glue solution with a solid content of 10%. Mix the positive electrode active material NCM811, conductive carbon black, and polyamic acid according to the mass parts of 80%, 10%, and 10%. Add NMP solvent to dissolve the mixture. The volume ratio of the polyamic acid solution to the solvent is 1.2:1. Stir for 20 minutes , The positive electrode slurry was prepared. The polyimide slurry containing functional groups -OH was coated on aluminum foil and dried at room temperature for 12 hours, and then subjected to heat treatment. The heat treatment process is to inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com