Printing and scratch-resistant black thermoplastic low-smoke halogen-free flame-retardant polyolefin cable sheathing compound

A cable sheath material, thermoplastic technology, applied in the direction of plastic/resin/wax insulators, circuits, electrical components, etc., to achieve the effect of improving wettability, strong ink adhesion, and surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

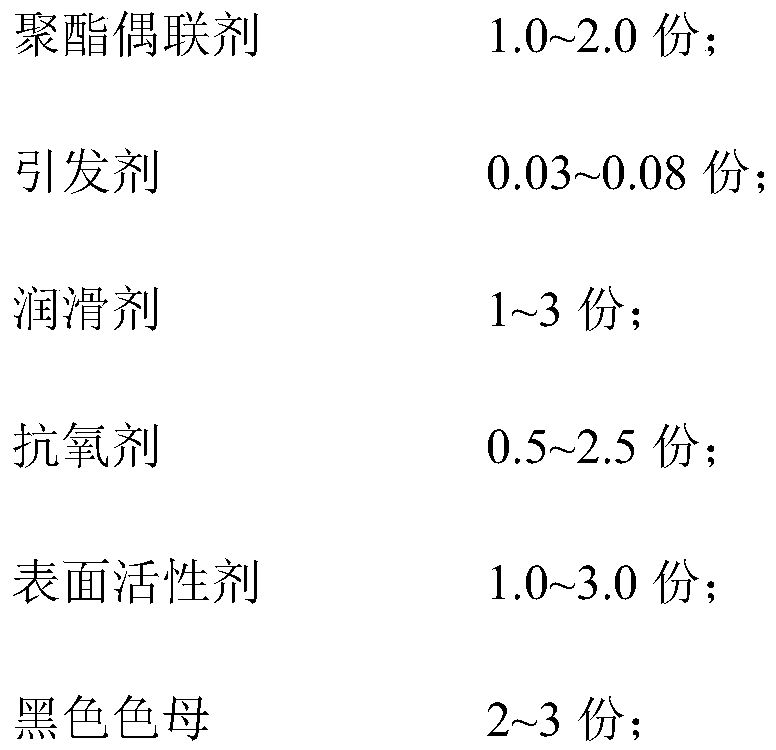

Embodiment 1

[0028] Weigh in parts by weight: 60 parts of ethylene-vinyl acetate copolymer with a mass % content of vinyl acetate monomer of 28%, ethylene-methyl acrylate copolymer with a mass % content of methyl acrylate monomer of 24% 20 parts, 20 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, D 50 110 parts of aluminum hydroxide of 1-2 microns, D 50 It is 30 parts of magnesium hydroxide of 1-2 micron, contains hydrophilic ester group on the molecular structure and contains the polyester that can be grafted to the double bond on the polymer matrix, such as the trade mark that is produced and sold by Lubrizol company is solplus c800 polyester 1.5 parts of coupling agent, 0.06 parts of dicumyl peroxide, 2 parts of magnesium stearate, tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol 1.5 parts, 0.8 parts of tris(2,4-di-tert-butylphenyl) phosphite, 2.0 parts of sorbitan polyoxyethylene ether oleate, black masterbatch (that is, "black masterba...

preparation example

[0030]First, 1.5 parts of the aforementioned polyester coupling agent, 0.06 parts of dicumyl peroxide, 2 parts of magnesium stearate, tetrakis[β-(3',5'-di-tert-butyl-4'-hydroxyphenyl 1.5 parts of propionic acid] pentaerythritol ester, 0.8 parts of tris(2,4-di-tert-butylphenyl) phosphite, 2 parts of sorbitan polyoxyethylene ether oleate, D 50 Put 110 parts of aluminum hydroxide of 1-2 microns and 30 parts of magnesium hydroxide into a high mixer and stir evenly, and then put 60 parts of the aforementioned ethylene-vinyl acetate copolymer and ethylene-methacrylate into the internal mixer together. 20 parts of the ester copolymer and 20 parts of the maleic anhydride grafted ethylene-vinyl acetate copolymer are evenly mixed, and are granulated through twin-screw and single-screw two-stage extrusion.

[0031] The performance test data of the black thermoplastic low-smoke halogen-free flame-retardant polyolefin cable sheath material prepared according to the above formula is:

[00...

Embodiment 2

[0034] Weigh in parts by weight: 60 parts of ethylene-butyl acrylate copolymer with a mass % content of butyl acrylate monomer of 28%, ethylene-ethyl acrylate copolymer with a mass % content of ethyl acrylate monomer of 18% 25 parts, ethylene-ethyl acrylate-maleic anhydride terpolymer 15 parts, D 50 110 parts of aluminum hydroxide of 1-2 microns, D 50 50 parts of magnesium hydroxide of 1-2 microns, 1.8 parts of polyester coupling agent, 0.08 parts of benzoyl peroxide, 1.5 parts of stearic acid amide, tetrakis[β-(3',5'-di-tert-butyl 1.6 parts of -4'-hydroxyphenyl) propionic acid] pentaerythritol ester, 0.8 parts of dioctadecyl thiodipropionate, 2.2 parts of sorbitan polyoxyethylene ether monolaurate and 3 parts of black masterbatch.

[0035] Since the preparation example of this embodiment is the same as the preparation example of Example 1, it is not repeated here.

[0036] Printing anti-scratch black thermoplastic low-smoke halogen-free flame-retardant polyolefin cable shea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com