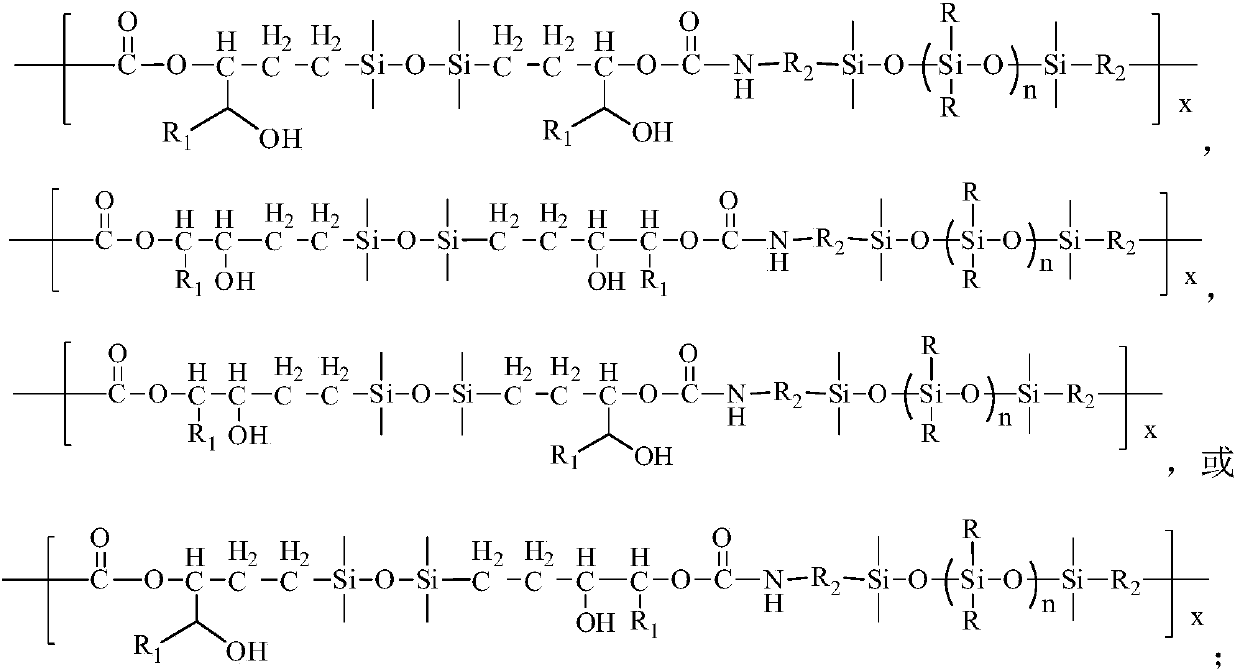

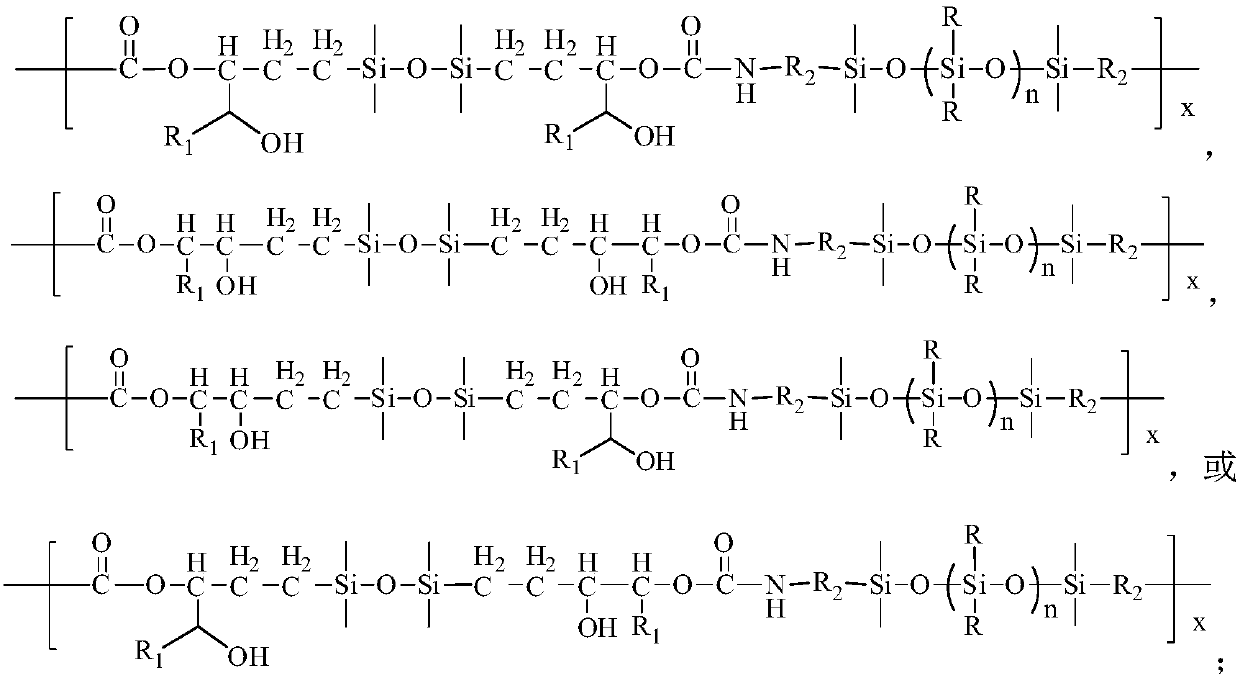

Non-isocyanate organosilicon-polyurethane block copolymer and synthesis method thereof

A non-isocyanate, block copolymer technology, applied in the field of non-isocyanate silicone-polyurethane block copolymer and its synthesis, can solve problems such as the introduction of target functional groups that limit polymerization efficiency, and achieve simple and efficient synthesis methods and chemical resistance. And the effect of excellent anti-penetration performance and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

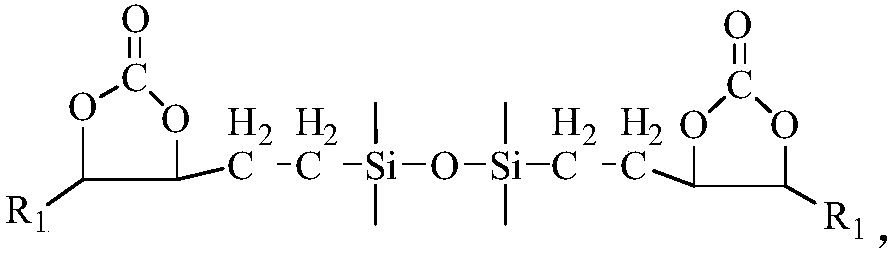

Method used

Image

Examples

Embodiment 1

[0044] α,ω-Aminoalkylpolysiloxane 10.0g with cyclocarbonate 1.2g (guaranteed an equimolar ratio of amino group to cyclocarbonate), mixed uniformly in a dioxane solvent, reacted at room temperature for 6h, and then heated to remove the solvent to obtain a non-isocyanate silicone-polyurethane block copolymer.

[0045] GPC got M n for 8315, M w It is 14634, and the molecular weight distribution index is 1.76.

Embodiment 2

[0047] The procedure described in Example 1 was repeated except that the α,ω-aminoalkylpolysiloxane was

[0048] GPC got M n for 7968, M w It is 15697, and the molecular weight distribution index is 1.97.

Embodiment 3

[0050] The procedure described in Example 1 was repeated except that the α,ω-aminoalkylpolysiloxane was

[0051] GPC got M n for 9324, M w It is 17156, and the molecular weight distribution index is 1.84.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com