Acrylonitrile copolymer binder and its application in lithium-ion batteries

A technology of lithium-ion batteries and adhesives, applied in the direction of nitrile copolymer adhesives, adhesive types, adhesives, etc., can solve the problems of battery performance degradation, large swelling degree, etc., to improve energy density and cycle performance , The effect of excellent battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

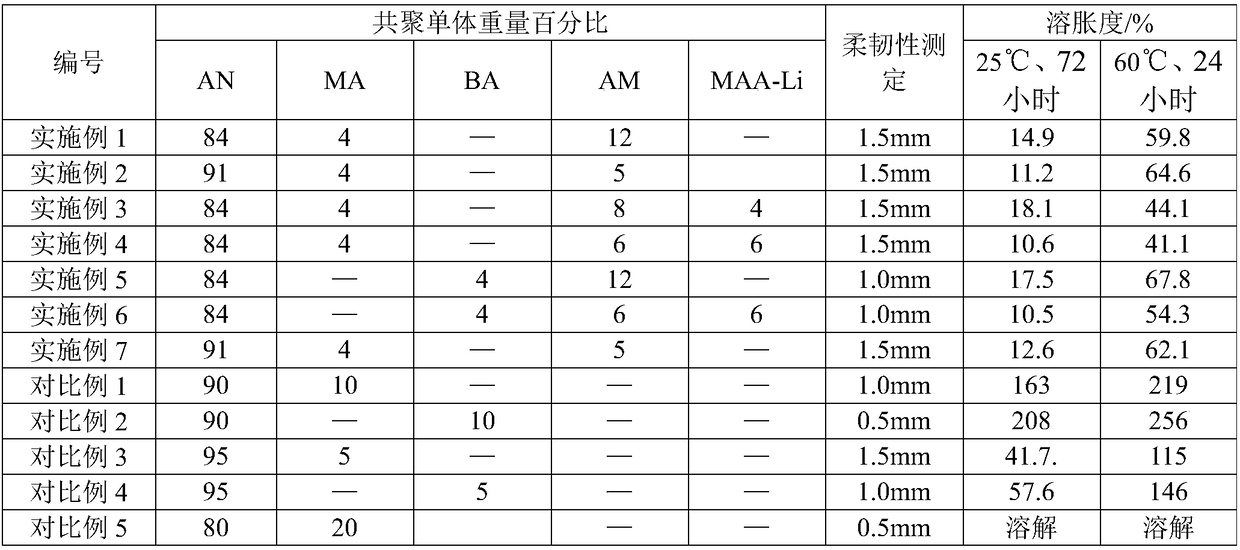

[0051] The preparation method of the terpolymer is as follows: firstly, an inert gas is introduced into the dispersion medium to drive oxygen, and then acrylonitrile, the second monomer acrylate monomer, the third monomer acrylamide monomer and as required The additives that may be used are raised to 40-80°C under an inert atmosphere, and after the temperature is constant, an initiator is added to carry out a polymerization reaction for 2-24 hours to obtain a polymer dispersion, and finally, through precipitation, filtration, washing, drying, crushing, and Sieve to get the acrylonitrile copolymer adhesive.

[0052] The preparation method of the quaternary copolymer adhesive is as follows: firstly add acrylate monomer to the dispersion medium, stir to dissolve, then add acrylonitrile, the second monomer acrylate monomer, The third monomer, the acrylamide monomer and the additives that may be used according to the needs, are heated to 40-80°C under an inert atmosphere. After the...

Embodiment approach

[0055] As an embodiment, the positive electrode material is LiFePO 4 、LiCoO 2 , LiNiO 2 , Li(Ni x co y mn z )O 2 or LiMn 2 o 4 at least one of the

[0056] A coated separator for lithium ion batteries, using the above-mentioned acrylonitrile copolymer adhesive, the amount of the adhesive accounts for 1-40wt% of the total solids, preferably 5-20wt%.

[0057] As an embodiment, the base film of the diaphragm is a polyolefin microporous film, a polymer woven diaphragm or a polymer non-woven diaphragm, and the filler is at least one of nanoscale inorganic ceramic particles or polymer powder materials.

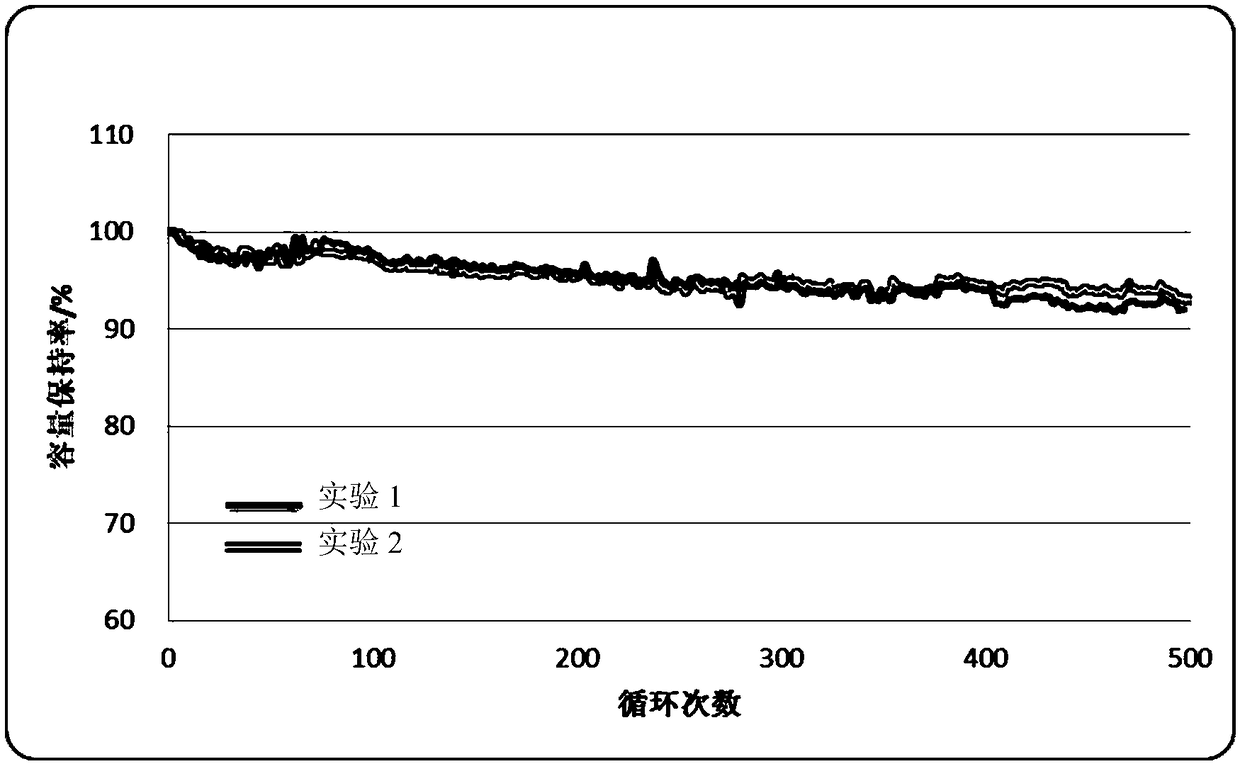

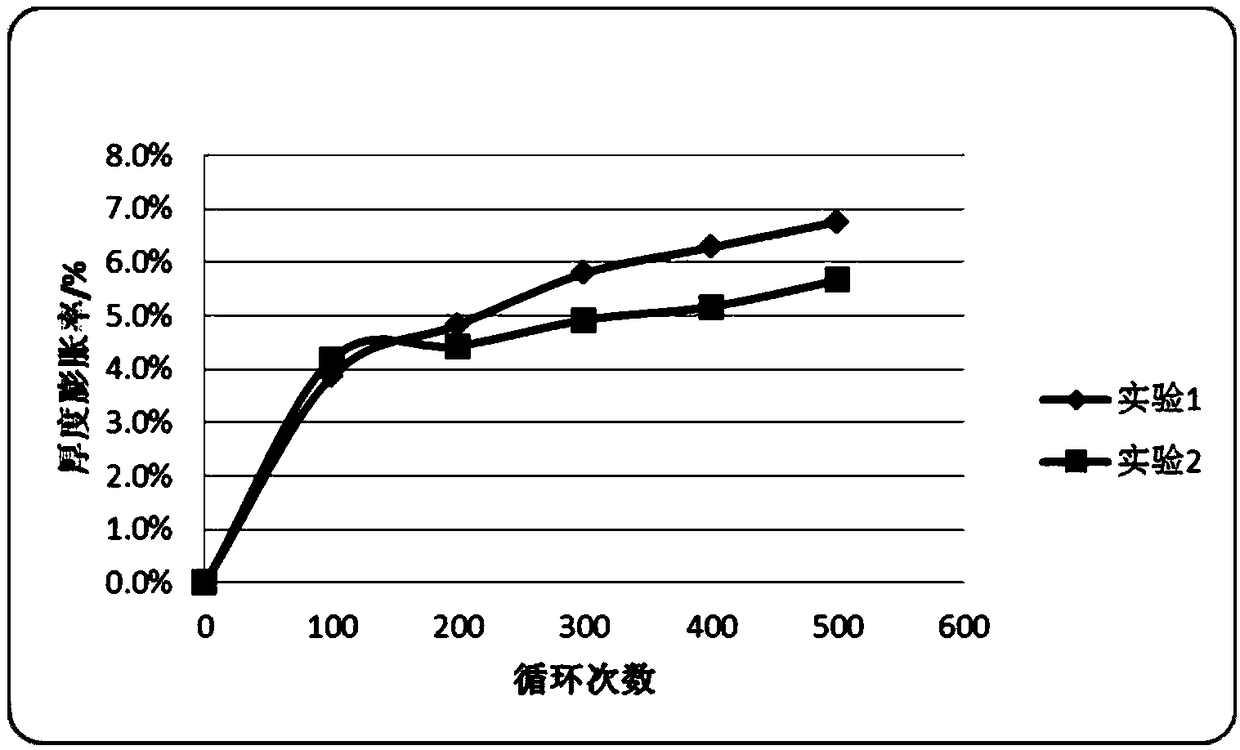

[0058] According to the acrylonitrile copolymer adhesive of the present invention, the coating diaphragm and lithium ion battery electrode sheet are produced according to the general coating diaphragm preparation route and lithium ion battery production process in this industry, assembled into an aluminum-plastic film flexible packaging battery, and the battery performance t...

Embodiment 1

[0059] Embodiment 1 Preparation of novel adhesive of the present invention

[0060]Add 900 parts of distilled water into the reaction vessel, start stirring, pass high-purity nitrogen gas to remove oxygen for 1 hour, then add 4 parts of methyl acrylate, 12 parts of acrylamide, and 84 parts of acrylonitrile, heat to 60°C under an inert atmosphere and keep the temperature constant; Then add 5 parts of 20% ammonium persulfate initiator solution to initiate the reaction, and finish after 4 hours of reaction. The binder is obtained after filtering, drying, pulverizing and sieving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com