Polymer emulsifying and thickening agent and preparation method thereof

A technology of emulsifying thickener and polymer, which is applied in the field of polymer emulsifying thickener and its preparation, can solve the problems of general emulsification effect of oily substances, weak lipophilicity, high production risk, etc., and achieve stable and controllable preparation method, Strong intermolecular force and good thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

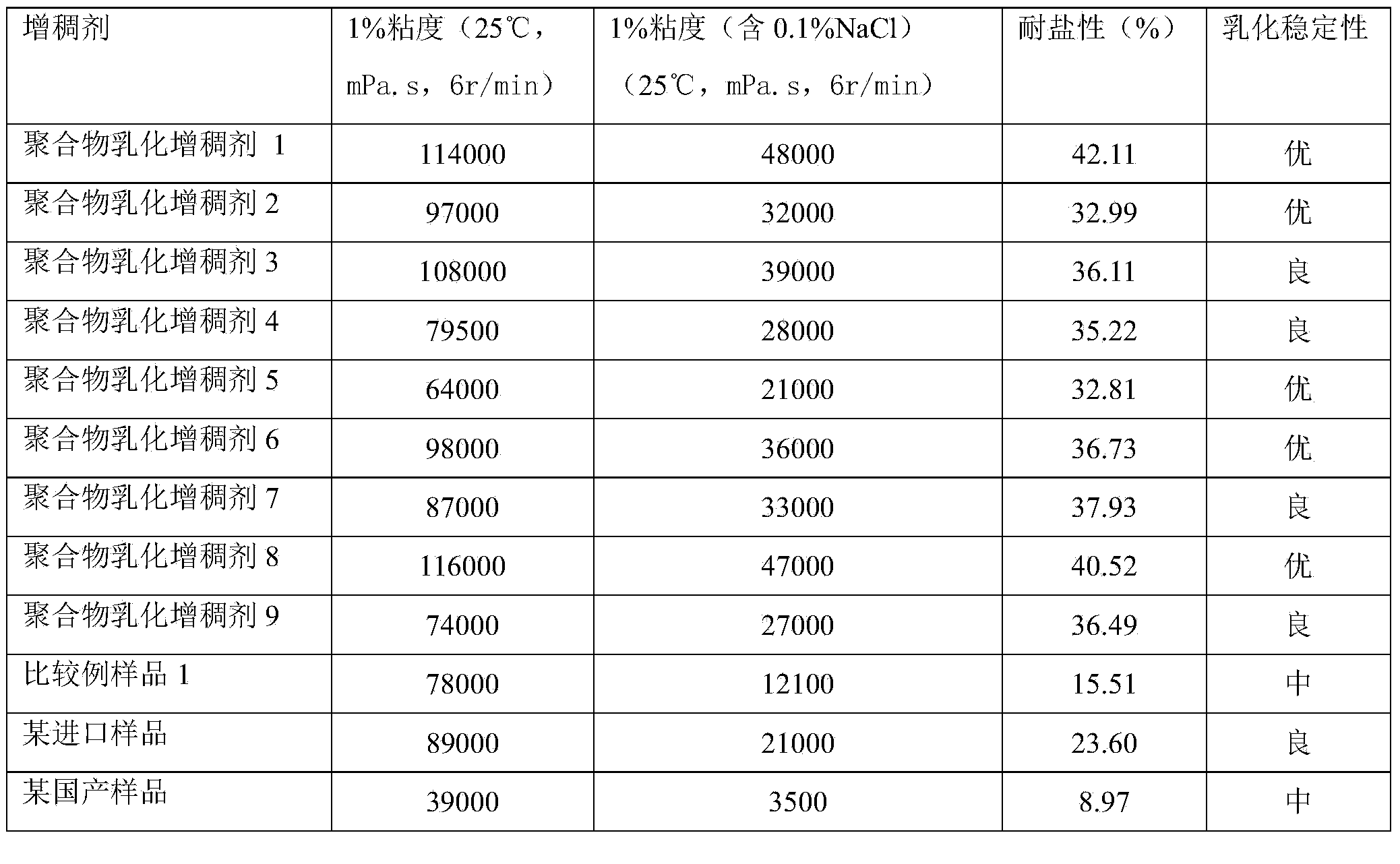

Examples

Embodiment 1

[0038] (1) Dissolve 161g of acrylic acid, 50g of 2-acrylamide-2 methylpropanesulfonic acid and 6g of N,N-dimethyl-N-dodecylmethylallyl ammonium chloride in 500g of tap water, add 38.3g ammonia gas, control the temperature below 10°C, adjust the pH value to 6.5-6.8, then add 0.001g mercaptoethanol, 0.3g sodium edetate and 0.15g trimethylolpropane diacrylate, stir well, get the aqueous phase;

[0039] (2) 3.5g glyceryl stearate and 15.5g sorbitan monooleate are added in 205g white mineral oil, stir evenly, obtain oily phase;

[0040] (3) The water phase of step (1) and the oil phase of step (2) are deoxygenated with nitrogen for 25-30 min respectively, and under the protection of nitrogen, the water phase of step (1) is added dropwise to step (2) while stirring. ) in the oil phase, the stirring speed is 28000 rev / min, and the dropping time is 25-30min; then add 0.1g of azobisisobutyronitrile, then add 7g of 1% ammonium persulfate aqueous solution and 7g of 1% sodium metabisulfi...

Embodiment 2

[0043] (1) Dissolve 100g of methacrylic acid, 200g of acrylamide and 3g of N,N-dimethyl-N-tetradecylmethylallyl ammonium chloride in 455g of deionized water, add 17.8g of ammonia gas, and control The temperature is lower than 10°C, adjust the pH value to 5.5-5.8, then add 0.00016g of mercaptoacetic acid, 0.4g of sodium diethylenetriaminepentaacetate and 0.1g of pentaerythritol triallyl ether, and stir evenly to obtain an aqueous phase;

[0044] (2) Add 2.1g of fatty alcohol polyoxyethylene ether-3 and 15g of sorbitan monooleate into 200g of heterogeneous white mineral oil, and stir evenly to obtain an oil phase;

[0045] (3) The water phase of step (1) and the oil phase of step (2) are deoxygenated with nitrogen for 35-40 min respectively, and under the protection of nitrogen, the water phase of step (1) is added dropwise to step (2) while stirring. ) in the oil phase, the stirring speed is 1000 rev / min, and the dropping time is 5-7min; then add 0.4g of azobisisovaleronitrile, a...

Embodiment 3

[0048] (1) Dissolve 100g of acrylic acid, 174g of vinylpyrrolidone and 1.4g of N,N-dimethyl-N-dodecylmethylallyl ammonium chloride in 314g of distilled water, add 66.3g of sodium carbonate, and control the temperature Below 10°C, adjust the pH value to 6.0-6.5, then add 0.01g of mercaptoethanol, 2g of sodium ethylenediaminetetraacetate and 0.95g of polyethylene glycol diacrylate, and stir evenly to obtain an aqueous phase;

[0049] (2) 3.3g of sorbitan monooleate was added in 400g of polyisobutene, and stirred evenly to obtain an oil phase;

[0050] (3) The water phase of step (1) and the oil phase of step (2) are deoxygenated with nitrogen for 25-30 min respectively, and under the protection of nitrogen, the water phase of step (1) is added dropwise to step (2) while stirring. ) in the oil phase, the stirring speed is 100 rpm, and the dropping time is 25-30min; add 0.5g of azobisisobutyronitrile, and then dropwise add 3g of 1% tert-butyl hydroperoxide aqueous solution and 3g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com