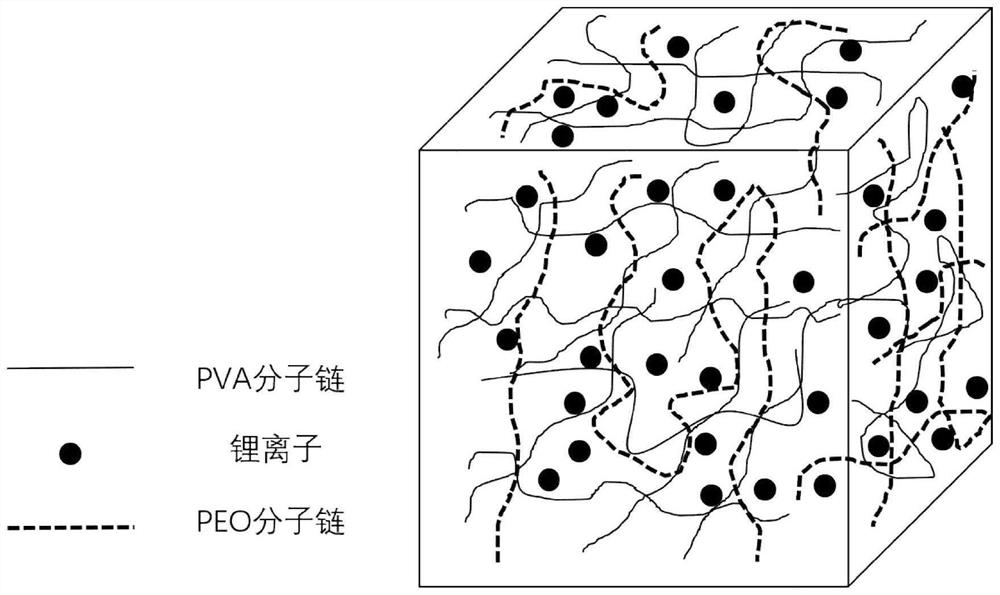

Preparation method of PVA/Li<+>/PEO interpenetrating network structure composite gel electrolyte

A composite gel and network structure technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of flammability, easy leakage of liquid electrolytes, and toxicity, and achieve high polarity, easy crystallization, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 称取2g聚乙烯醇(PVA)溶于去20ml离子水中并于95℃加热搅拌至完全溶解,获得稳定的PVA溶液。将上述PVA溶液浇筑在模具中,-20℃冷冻24h,解冻5h,重复4次。制备的聚乙烯醇(PVA)膜,将PVA膜浸入在30ml,9wt%LiCl溶液中浸泡10h,室温干燥,静置时间为3h;再在乙醇钠浓度为8wt%的乙醇钠-乙醇溶液中浸泡8h,室温干燥,静置时间为3h,得到干燥的凝胶。将相对环氧乙烷摩尔比分别为0.1mol%、0.1mol%的N,N-亚甲基双丙烯酰胺(MBAA)、过硫酸铵(APS)与环氧乙烷(EO)溶液混合,配制环氧乙烷混合溶液。将上述干燥的凝胶浸入环氧乙烷混合溶液中浸泡24h,室温干燥,静置时间为3~5h,制得PVA / Li + / PEO互穿网状结构复合凝胶电解质。PVA / Li + / PEO互穿网状结构复合凝胶电解质的离子电导率为0.5×10 -4 S / cm,拉伸强度为1.395MPa,断裂伸长率为241.53%。

Embodiment 2

[0028] 称取2g聚乙烯醇(PVA)溶于去10ml离子水中并于90℃加热搅拌至完全溶解,获得稳定的PVA溶液。将上述PVA溶液浇筑在模具中,-25℃冷冻24h,解冻5h,重复4次。制备的聚乙烯醇(PVA)膜,将PVA膜浸入在30ml,9wt%LiPF 6 溶液中浸泡10h,室温干燥,静置时间为4h;再在乙醇钠浓度为8wt%的乙醇钠-乙醇溶液中浸泡8h,室温干燥,静置时间为4h,得到干燥的凝胶。将相对环氧乙烷摩尔比分别为0.1mol%、0.1mol%的N,N-亚甲基双丙烯酰胺(MBAA)、过硫酸铵(APS)与环氧乙烷(EO)溶液混合,配制环氧乙烷混合溶液。将上述干燥的凝胶浸入环氧乙烷混合溶液中浸泡24h,室温干燥,静置时间为4h,制得PVA / Li + / PEO互穿网状结构复合凝胶电解质。PVA / Li + / PEO互穿网状结构复合凝胶电解质的离子电导率为0.9×10 -3 S / cm,拉伸强度为3.105MPa,断裂伸长率为400.53%。

Embodiment 3

[0030] 称取2g聚乙烯醇(PVA)溶于去8ml离子水中并于93℃加热搅拌至完全溶解,获得稳定的PVA溶液。将上述PVA溶液浇筑在模具中,-18℃冷冻24h,解冻5h,重复4次。制备的聚乙烯醇(PVA)膜,将PVA膜浸入在30ml,9wt%LiClO 4 溶液中浸泡10h,室温干燥,静置时间为5h;将干燥的凝胶在乙醇钠浓度为8wt%的乙醇钠-乙醇溶液中浸泡8h,室温干燥,静置时间为5h。将相对环氧乙烷摩尔比分别为0.1mol%、0.1mol%的N,N-亚甲基双丙烯酰胺(MBAA)、过硫酸铵(APS)与环氧乙烷(EO)溶液混合,配制环氧乙烷混合溶液。将上述干燥的凝胶浸入环氧乙烷混合溶液中浸泡24h,室温干燥,静置时间为5h,制得PVA / Li + / PEO互穿网状结构复合凝胶电解质。PVA / Li + / PEO互穿网状结构复合凝胶电解质的离子电导率为0.8×10 -4 S / cm,拉伸强度为2.367MPa,断裂伸长率为312.63%。

[0031] 热重分析(TGA):以TGA进行测试时,实验气氛为氮气,测试温度为0-300℃,升温速率为10℃ / min。

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com