Tax stamp ink digital ink jet and preparation method thereof

A printing ink, digital inkjet technology, applied in ink, dyeing, textile and papermaking, etc., can solve the problems of easy delamination or precipitation, complex production process, poor stability, etc., to achieve good dispersion stability and storage stability , shorten the process flow, increase the effect of dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

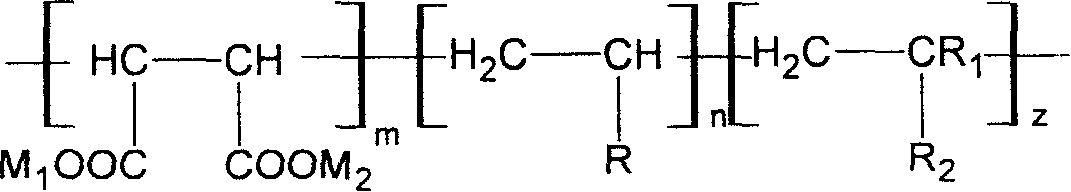

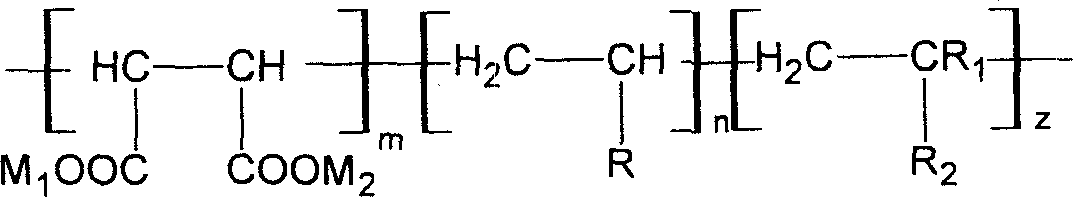

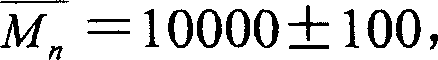

[0026] The preparation of embodiment 1 red ink

[0027] Get 4g maleic anhydride-methyl acrylate-butyl methacrylate copolymer ( M n ‾ = 10000 ± 100 , Molar ratio maleic anhydride: methyl acrylate: butyl methacrylate=1:0.5:1), add 0.4g sodium hydroxide, 51g deionized water, heat to dissolve the polymer completely, then add 5g of C.I. pigment red in turn 112, 1g of OP-15 emulsifier, 3g of ethanol, 15g of diethylene glycol, 10g of ethylene glycol, 10g of glycerol, and 1g of n-butanol were stirred with a mixer at 600 rpm for 25 minutes, emulsified Stir at a high speed of 10,000 rpm for 50 minutes, pulverize with a sand mill for 30 minutes, adjust the pH value to 8, and filter with a 0.5-1 μm microporous membrane to obtain a water-based pigment magenta ink. The physical properties of this ink at 20°C are as follows: surface tension σ=28.7mN / m, viscosity η=5.5...

Embodiment 2

[0028] The preparation of embodiment 2 yellow ink

[0029] Get 3g methyl methacrylate-maleic anhydride-acrylonitrile-butyl acrylate copolymer ( M n ‾ = 30000 ± 200 , Molar ratio methyl methacrylate: maleic anhydride: acrylonitrile: butyl acrylate=1:1.5:0.3:1), add 0.5g potassium hydroxide, 54g deionized water, heat to dissolve the polymer completely, and then add 6g of C.I. Pigment Yellow 17, 1.5g of Tween 80, 5g of N-methyl-2-pyrrolidone, 5g of 1,3-propylene glycol, 10g of polyethylene glycol 200, 10g of triethylene glycol, 5g of iso Propanol was stirred with a mixer at 500 rpm for 50 minutes, an emulsifier at 15,000 rpm at a high speed for 70 minutes, and a sand mill for 120 minutes. Finally, adjust the pH value to 7 and filter with a 0.5-1 μm microporous membrane. That is, the water-based pigment yellow ink is obtained. The physical properties of th...

Embodiment 3

[0030] The preparation of embodiment 3 blue ink

[0031] Get 5g styrene-maleic anhydride-acrylamide-butyl methacrylate copolymer ( M n ‾ = 25000 ± 200 , Molar ratio styrene: maleic anhydride: acrylamide: butyl methacrylate=1:2:0.5:1), add 20% ammonia water 5g, deionized water 58g, heat to make it dissolve completely, then add 4g of C.I. Pigment blue 56, 2g Pingpingjia O-25, 3g isopropanol, 3g triethanolamine, 5g 1,6-hexanediol, 10g diethylene glycol, 5g polyethylene glycol 400, 5g 2-pyrrolidone , stir with a mixer at 800 rpm for 40 minutes, emulsifier at 20,000 rpm for 30 minutes at high speed, sand mill for 80 minutes, finally adjust the pH value to 6, and filter with a microporous membrane of 0.5 to 1 μm to obtain Water-based pigment blue ink. The physical properties of this ink at 20°C are as follows: surface tension σ=29.8mN / m, viscosity η=4.85cP, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Z-average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com