Carbon nano tube complex filled with lubricant additive as well as preparation method and application of carbon nano tube complex

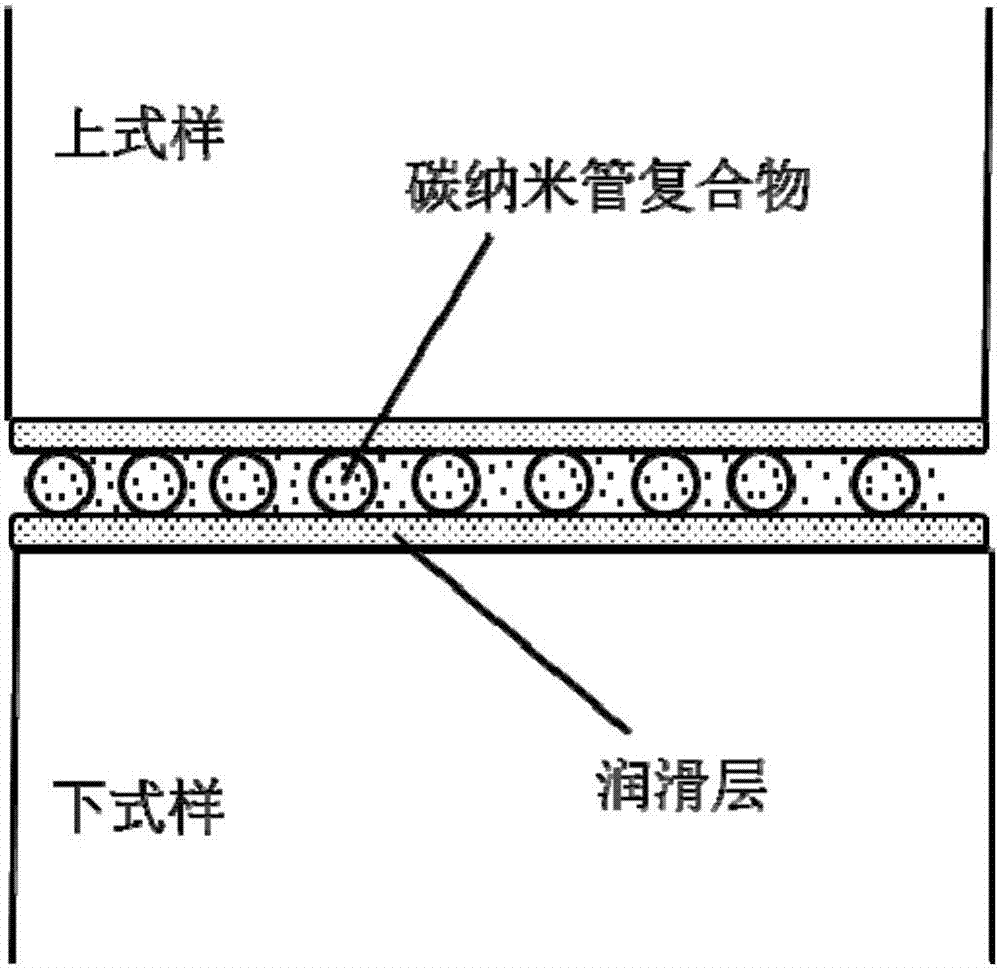

A carbon nanotube and filling lubrication technology, which is applied in the direction of lubricating compositions, additives, petroleum industry, etc., can solve the problems of reduced lubricating performance, weak load-carrying capacity, and inability to form chemical adsorption film lubrication of metals, so as to improve stability , increase the lubricating effect, reduce the friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of preparation method of the carbon nanotube composite filled with oleic acid of the present embodiment 1, comprises the following steps:

[0048] (1) 80 parts of the carbon nanotubes are cut and shortened by mechanical ball milling, so that the aspect ratio thereof is 10:1 to 20:1;

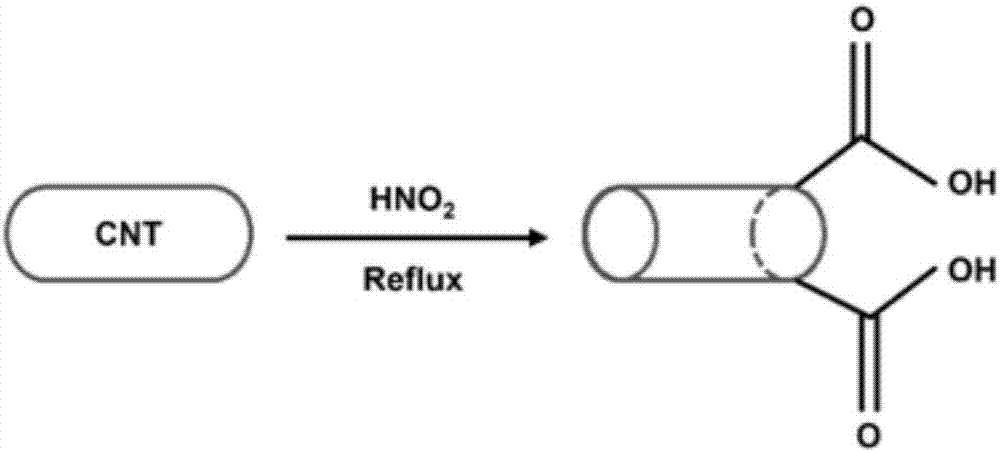

[0049] (2) adding the treated carbon nanotubes into 400mL of concentrated nitric acid and 160mL of sulfuric acid mixed solution, under mechanical stirring, heating to reflux for 2h, and then cleaning and drying to obtain acidified carbon nanotubes;

[0050] (3) 20 parts of oleic acid was sheared and dispersed in 5L deionized water to obtain an emulsion, then acidified carbon nanotubes were added, mechanically stirred under ultrasonic conditions, and filled at 60°C for 13 hours. The carbon nanotube composite filled with oleic acid is prepared by washing with organic solvent, suction filtration, vacuum drying and ultrafine pulverization.

Embodiment 2

[0052] A preparation method of a carbon nanotube composite filled with dihydrocarbyl pentasulfide (RC2540) of the present embodiment 2, comprising the following steps:

[0053] (1) 80 parts of the carbon nanotubes are cut and shortened by mechanical ball milling, so that the aspect ratio thereof is 10:1 to 20:1;

[0054] (2) adding the treated carbon nanotubes into 400mL concentrated nitric acid and 160mL sulfuric acid mixed solution, under mechanical stirring, heating and refluxing for 120min, then cleaning and drying to obtain acidified carbon nanotubes;

[0055] (3) Disperse 20 parts of dihydrocarbyl pentasulfide in 5L of deionized water by shearing to obtain a lubricant additive emulsion, then add acidified carbon nanotubes, mechanically stir under ultrasonic conditions, fill at 80°C for 13 hours, and the filling is complete Finally, the carbon nanotube compound filled with dihydrocarbyl pentasulfide is obtained by washing with an organic solvent, suction filtration, vacuu...

Embodiment 3

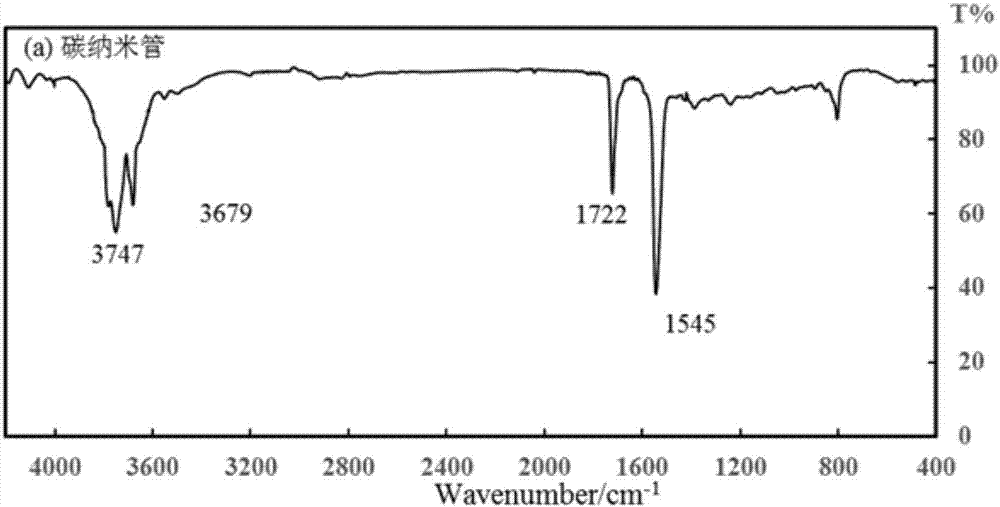

[0057] In order to prove that the carbon nanotube composites prepared in Examples 1-2 are filled with lubricating additives, the present embodiment uses infrared spectroscopy (IR) analysis to characterize the carbon nanotube composites prepared in Examples 1-2. According to the characteristic difference of the absorption peaks in the infrared region of the carbon nanotubes before and after filling, it is judged whether the carbon nanotubes have been filled with the lubricating additive.

[0058] First, conduct infrared spectrum analysis on the carbon nanotubes that have been acidified and not filled. After being oxidized by acid, the carbon nanotubes are -1 Office and 1722cm -1 The absorption peaks of hydroxyl and carboxyl groups appeared nearby, indicating that the acidified carbon nanotubes were equipped with oxygen-containing functional groups, at 1543cm -1 The planar absorption peak of the carbon ring structure appears at , which proves that the tubular structure of carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com