Preparation method of intelligent stress response material

A smart material and stress technology, applied in the field of materials, can solve the problems of poor stress response ability, low energy absorption rate, no self-healing performance, etc., and achieve the effect of good energy absorption rate and good stress response ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

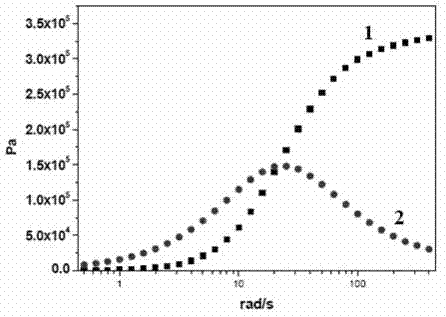

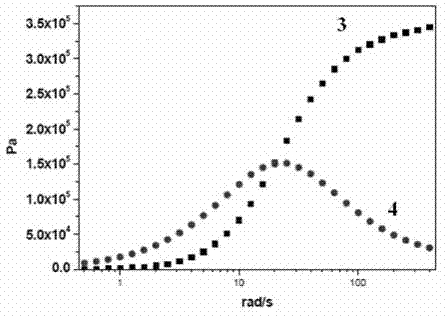

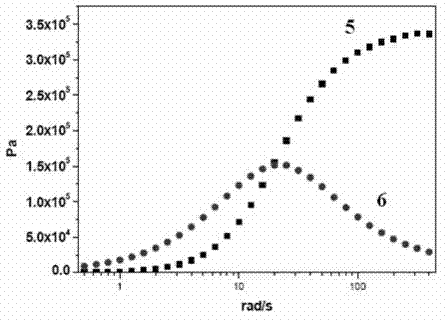

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing a stress-responsive smart material, comprising the following steps:

[0034] A) Mix polydiorganosiloxane, boron-containing compound, bifunctional chain extender and functional modifier, react and dry to obtain a stress-responsive smart material precursor;

[0035] B) Post-processing the precursor of the stress-responsive smart material to obtain a stress-responsive smart material;

[0036] The post-treatment is one or more of heating, microwave radiation, mixing with a dispersant and then removing the dispersant, extrusion and rolling.

[0037] In the invention, polydiorganosiloxane, boron-containing compound, bifunctional chain extender and functional modifier are firstly mixed, reacted, and dried to obtain a stress-responsive intelligent material precursor.

[0038] The polydiorganosiloxane is dihydroxyl-terminated polydimethylsiloxane, and the molecular weight of the polydiorganosiloxane in the present invention is prefe...

Embodiment 1

[0070] 25 g of cyclohexyl ethylene borate and 75 g of polydimethylsiloxane with a molecular weight of 4000 were evenly mixed and stirred at 110° C. for 4 hours to obtain a first reaction liquid.

[0071] 5 g of bifunctional chain extender hexamethyl diisocyanate was added to the first reaction liquid, and the reaction was continued with stirring for 2 hours at a reaction temperature of 40° C. to obtain a second reaction liquid.

[0072] 3 g of functional modifier tetraisobutyl titanate was added to the second reaction liquid, and stirred and reacted at 70° C. for 8 hours to obtain a primary reaction product of nanoscale stress-responsive intelligent material.

[0073] Drying the primary reaction product of the nanoscale stress-responsive smart material at 70° C. for 24 hours can obtain a precursor of the stress-responsive smart material.

[0074] The stress-responsive smart material precursor was heated at 140° C. for 2 hours to obtain a stress-responsive smart material.

[0...

Embodiment 2

[0093] 15 g of tricresyl borate and 85 g of polydimethylsiloxane with a molecular weight of 6000 were evenly mixed and stirred at 90° C. for 3 hours to obtain a first reaction liquid.

[0094] 6 g of bifunctional chain extender hexamethyl diisocyanate was added to the first reaction liquid, and the reaction was continued with stirring for 6 hours at a reaction temperature of 60° C. to obtain a second reaction liquid.

[0095] To the second reaction liquid, 3 g of the functional modifier tetraisobutyl titanate was added to the first reaction liquid, and stirred and reacted at 70° C. for 8 hours to obtain the primary reaction product of the nanoscale stress-responsive smart material.

[0096] The primary reaction product of the nanoscale stress-responsive smart material was dried at 60° C. for 20 hours to obtain a precursor of the stress-responsive smart material.

[0097] The stress-responsive smart material precursor was heated at 180° C. for 0.5 hour to obtain a stress-respon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com