Printing method adopting photo-curing 3D printer and 3D printing system

A 3D printing and light curing technology, applied in the field of 3D printing, can solve the problems of intermittent printing process and affect printing efficiency, and achieve the effect of high molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

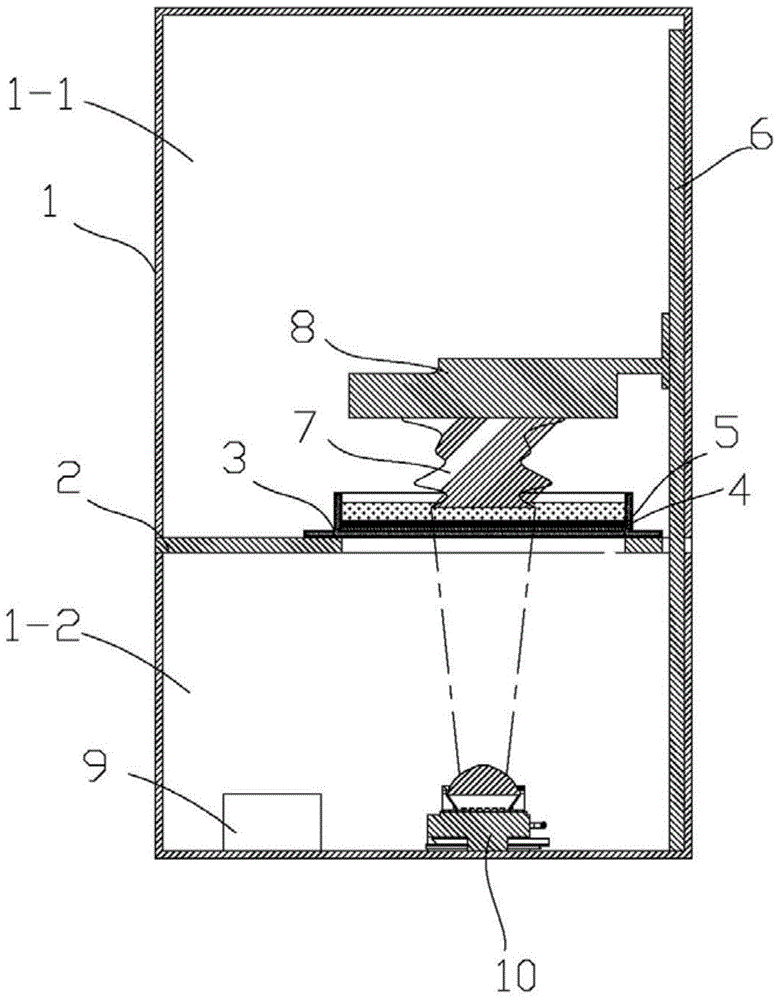

[0025] refer to figure 1 , a light-curing 3D printer, which has a frame 1 and a middle plate 2 arranged in the frame 1 . The middle plate 2 divides the inside of the frame 1 into an upper space 1-1 and a lower space 1-2. The photosensitive resin pool 3 is arranged on the middle plate 2 and contains liquid photosensitive resin inside. A Fresnel lens 4 for uniform light and an LCD liquid crystal display unit 5 are sequentially covered on the inner surface of the bottom of the photosensitive resin pool 3 .

[0026] The guide rail column 6 is arranged on one side inside the frame 1 , it passes through the middle plate 2 , and extends from the lower space 1-2 to the upper space 1-1. The carrying platform 8 for carrying the cured object 7 can move vertically along the guide rail column 6 . Specifically, the guide rail column 6 may be a rotatable lead screw, and the end of the bearing platform 8 associated with the guide rail column 6 may be a nut seat of the lead screw. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com