Macromolecule heat conduction material and preparation method thereof

A technology of heat-conducting materials and polymers, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of reduced heat conduction effect, dry cracking and powdering of heat-conducting paste, short effective life of heat-conducting paste, etc., to achieve low cost and medium good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

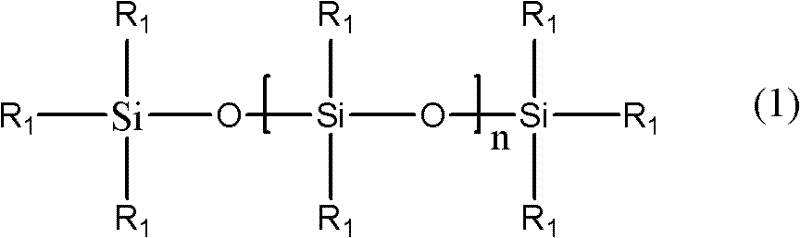

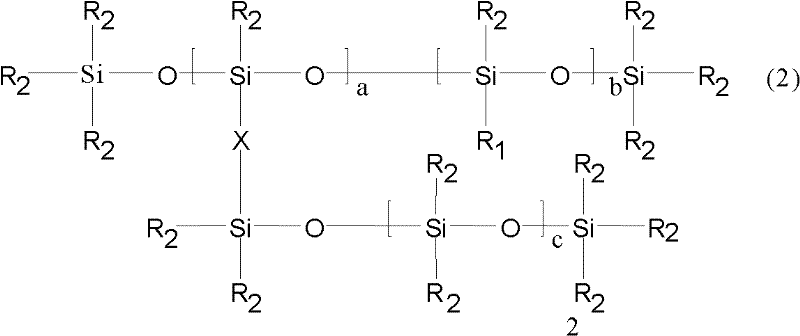

Method used

Image

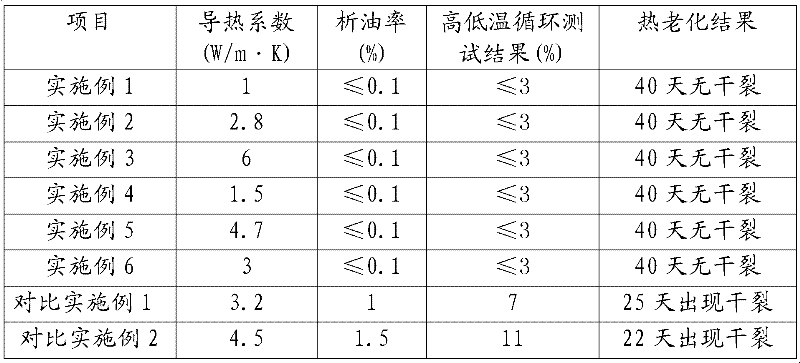

Examples

Embodiment 1

[0030] Accurately weigh 30 g of branched chain silicone oil, 60 g of linear silicone oil, 1 g of γ-aminopropyltrimethoxysilane and 5 g of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, Add the above-mentioned components into a double planetary power mixer and stir for 30 minutes, add 210g of spherical alumina to the above mixture, stir for 30 minutes, add 90g of zinc oxide whiskers, stir for 30 minutes, under the condition of a vacuum of -0.1Mpa Next, stir for 30 minutes;

[0031] Wherein, the branched silicone oil has a viscosity of 1,000,000 mPa·s, and the linear silicone oil has a viscosity of 200 mPa·s.

Embodiment 2

[0033] Accurately weigh 15g of branched chain silicone oil, 80g of linear silicone oil, 1.5g of γ-aminopropyltriethoxysilane, 1.5g of γ-methacryloxypropyltrimethoxysilane, N,N′-bis-[ 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine 2g, add the above-mentioned components into a double planetary power mixer and stir for 60 minutes, add spherical aluminum powder to the above-mentioned mixture 490g of the mixture with spherical zinc powder, stirred for 60 minutes, added 210g of the mixture of potassium carbonate whiskers and silicon nitride whiskers, stirred for 60 minutes, and stirred for 60 minutes under the condition of vacuum degree of -0.1Mpa.

[0034] Wherein, the branched silicone oil has a viscosity of 10000 mPa·s, and the linear silicone oil has a viscosity of 2000 mPa·s.

Embodiment 3

[0036] Accurately weigh 5 g of branched chain silicone oil, 85 g of linear silicone oil, 2.5 g of γ-methacryloxypropyl trimethoxysilane, 2.5 g of γ-glycidyl etheroxypropyl trimethoxysilane, 1,2-bis( 2.5g of 3,5-di-tert-butyl-4-hydroxy-phenylpropionic acid) hydrazine, 2.5g of tris[2,4-di-tert-butylphenyl]phosphite, add the above components to the double planetary power Stir in a mixer for 45 minutes, add 880 g of a mixture of spherical zinc powder, spherical copper powder and spherical alumina to the above mixture, stir for 45 minutes, add 220 g of a mixture of silicon nitride whiskers and β-SiC whiskers, and stir for 45 minutes , Stirring for 45 minutes under the condition of vacuum degree of -0.1Mpa.

[0037] Wherein, the viscosity of the branched silicone oil is 80000 mPa·s, and the viscosity of the linear silicone oil is 10 mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com