Novel PLGA-PEG-PLGA multipolymer microbubble ultrasound contrast agent and preparation method thereof

A technology of PLGA-PEG-PLGA and ultrasonic contrast agent, which is applied in the field of ultrasonic medical diagnosis and treatment, can solve the problems of controlling the particle size of microbubbles, the thickness of the particle size distribution envelope, and the limitations of elastic and nonlinear acoustic properties, and achieve good results. The effect of backscattering performance, simple and convenient production method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Synthesis and characterization of PLGA-PEG-PLGA copolymer

[0021] Put 15g (mass percentage 40%) polyethylene glycol with Mw of 1500 in the there-necked flask, stir for 3h under vacuum at 150°C, add 3.2g glycolide, 19.3g lactide (glycolide and lactide The molar ratio is 1:4) and 0.04 g of the catalyst stannous octoate, reacted for 8 hours under nitrogen protection to obtain the product. The product was dissolved in chloroform, purified by ethanol precipitation, and dried at room temperature to constant weight. The average molecular weight that adopts high-efficiency gel permeation chromatography analyzer to measure copolymer is 5880dal, Fourier transform infrared spectrum, 1 The H NMR spectrum shows a typical PLGA-PEG-PLGA structure.

Embodiment 2

[0022] Embodiment 2: Preparation of PLGA-PEG-PLGA microbubble

[0023] Microbubbles were prepared by water / oil / water double emulsion-solvent evaporation method. 1ml of PLGA-PEG-PLGA dichloromethane / ethyl acetate mixed solution with a concentration of 50mg / ml was added to 0.1ml of normal saline, stirred at a speed of 10,000 rpm for 1min to obtain primary emulsion, and poured into 4ml of 3% polyvinyl alcohol aqueous solution, Stir at 10,000 rpm for 1 min, then add 15ml of 3% polyvinyl alcohol aqueous solution, stir magnetically at 400 rpm for 3 h to completely evaporate the organic solvent, centrifuge, wash with distilled water, add antifreeze glycerin to the obtained microbubbles, and vacuum freeze-dry Then fill it with inert gas perfluoropropane and store it at low temperature.

Embodiment 3

[0024] Example 3: Characterization of PLGA-PEG-PLGA microbubbles

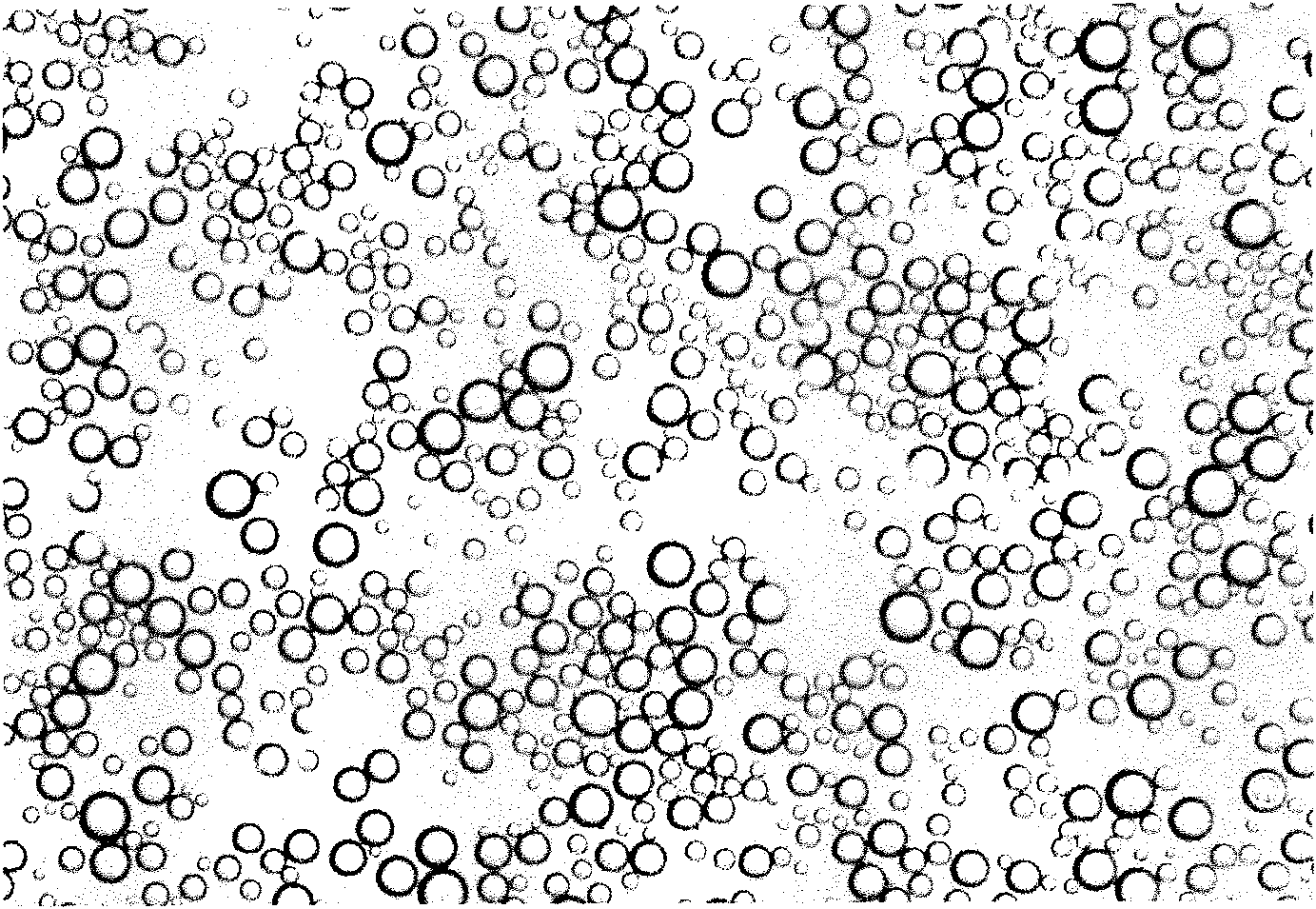

[0025] Disperse the microbubbles in normal saline, observe under the inverted microscope that the microbubbles are spherical, smooth in surface, well dispersed, non-adhesive, and relatively uniform in size (see figure 1 ). Take an appropriate amount of microbubble powder and disperse it in physiological saline, and the laser particle size analyzer measures the particle size of the microspheres to be 1.1-7.2 μm, with an average of 3.8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com