A kind of synthetic method of ethylene glycol polyester plasticizer

A technology of polyester plasticizer and synthesis method, which is applied in the synthesis field of ethylene glycol polyester plasticizer, can solve the problems affecting the practical application performance of products and the softening of PVC materials, etc., and achieve good antistatic effect and product Excellent appearance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

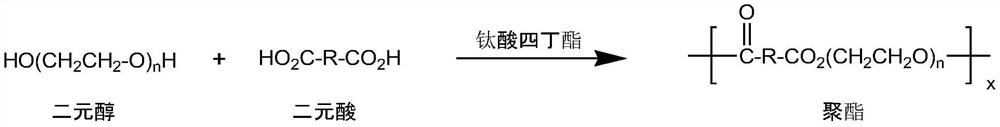

Method used

Image

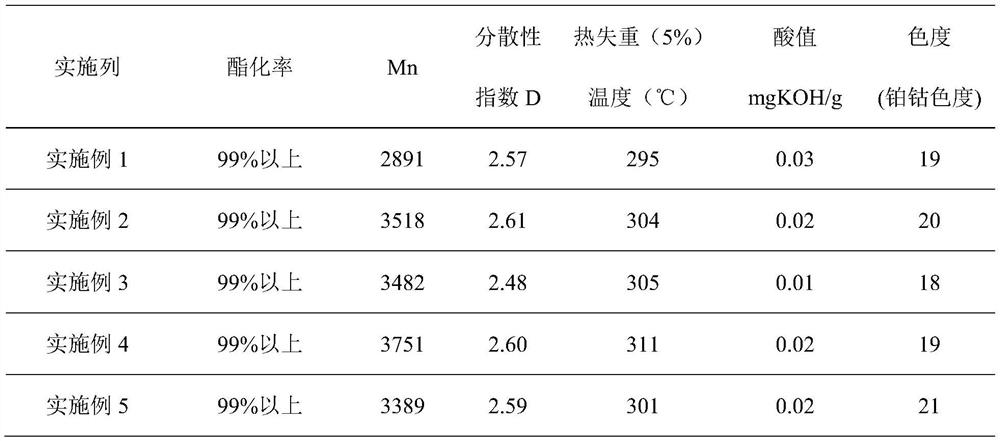

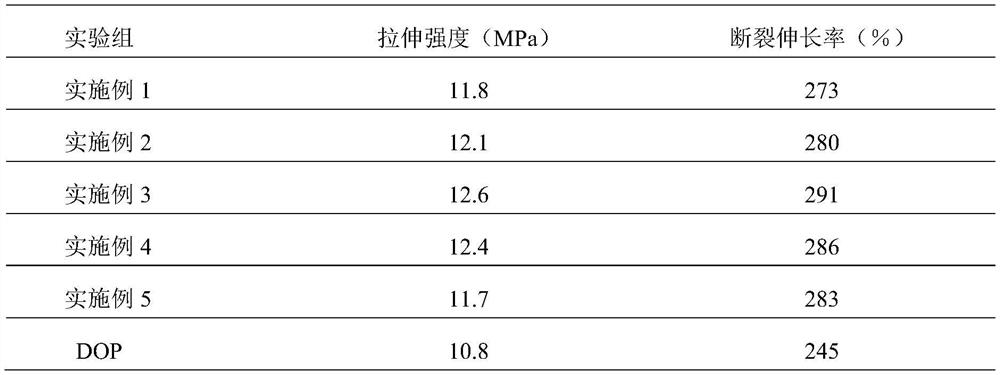

Examples

Embodiment 1

[0032] Weigh 2KG of ethylene glycol and 4.26KG of 2-methylsuccinic acid into a 10L autoclave. Heating was started under the protection of nitrogen, the temperature in the kettle rose to 135° C., and stirring was started. Under the protection of nitrogen, 1.5 g of tetraisopropyl titanate was added, and the temperature was continuously raised to carry out the esterification reaction. When the pressure in the kettle reaches 11KG and the temperature in the kettle is 184-186°C, start to drain water until the pressure in the kettle drops to 0 (or nitrogen flow pressure), and it takes 45 minutes. The temperature was slowly raised to 195°C, and the water was drained under normal pressure for 10 minutes under the protection of nitrogen flow until no distillate was discharged.

[0033] Under the protection of nitrogen, the temperature in the kettle rose to 215°C. Turn on the vacuum device, depressurize and drain water under the condition of vacuum degree of 700Pa, further polycondensa...

Embodiment 2

[0035]Weigh 1.2KG of diethylene glycol, 2.2KG of tetraethylene glycol and 3.0KG of 2-methylsuccinic acid into a 10L autoclave. Heating was started under the protection of nitrogen, the temperature in the kettle rose to 135° C., and stirring was started. Under the protection of nitrogen, 1.5 g of tetraisopropyl titanate was added, and the temperature was continuously raised to carry out the esterification reaction. When the pressure in the kettle reaches 11KG and the temperature in the kettle is 184-186°C, start to drain water until the pressure in the kettle drops to 0 (or nitrogen flow pressure), and it takes 45 minutes. The temperature was slowly raised to 195°C, and the water was drained under normal pressure for 10 minutes under the protection of nitrogen flow until no distillate was discharged.

[0036] Under the protection of nitrogen, the temperature in the kettle rose to 215°C. Turn on the vacuum device, depressurize and drain water at a vacuum degree of 700Pa, furth...

Embodiment 3

[0038] Weigh 3.6KG of triethylene glycol and 3.17KG of 2-methylsuccinic acid into a 10L autoclave. Heating was started under the protection of nitrogen, the temperature in the kettle rose to 135° C., and stirring was started. Under the protection of nitrogen, 1.5 g of tetraisopropyl titanate was added, and the temperature was continuously raised to carry out the esterification reaction. When the pressure in the kettle reaches 11KG and the temperature in the kettle is 184-186°C, start to drain water until the pressure in the kettle drops to 0 (or nitrogen flow pressure), and it takes 45 minutes. The temperature was slowly raised to 195°C, and the water was drained under normal pressure for 10 minutes under the protection of nitrogen flow until no distillate was discharged.

[0039] Under the protection of nitrogen, the temperature in the kettle rose to 215°C. Turn on the vacuum device, depressurize and drain water at a vacuum degree of 700Pa, further polycondensate for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com