Bonding method for hydrogel and elastomer, and product and application thereof

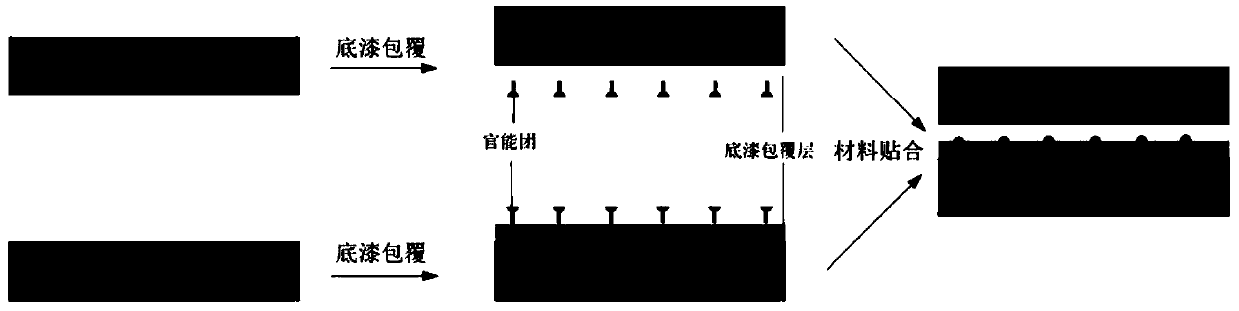

A bonding method and hydrogel technology, applied in coatings, primers, conjugated diene coatings, etc., can solve the problem that hydrogel materials cannot be applied, hydrogel materials are easy to fall off, and the mechanical properties of materials are affected. problem, to achieve the effect of simple and easy bonding method, wide applicability and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This embodiment provides a method for bonding polyacrylamide hydrogel and polydimethylsiloxane elastomer, and the bonding method specifically includes the following steps:

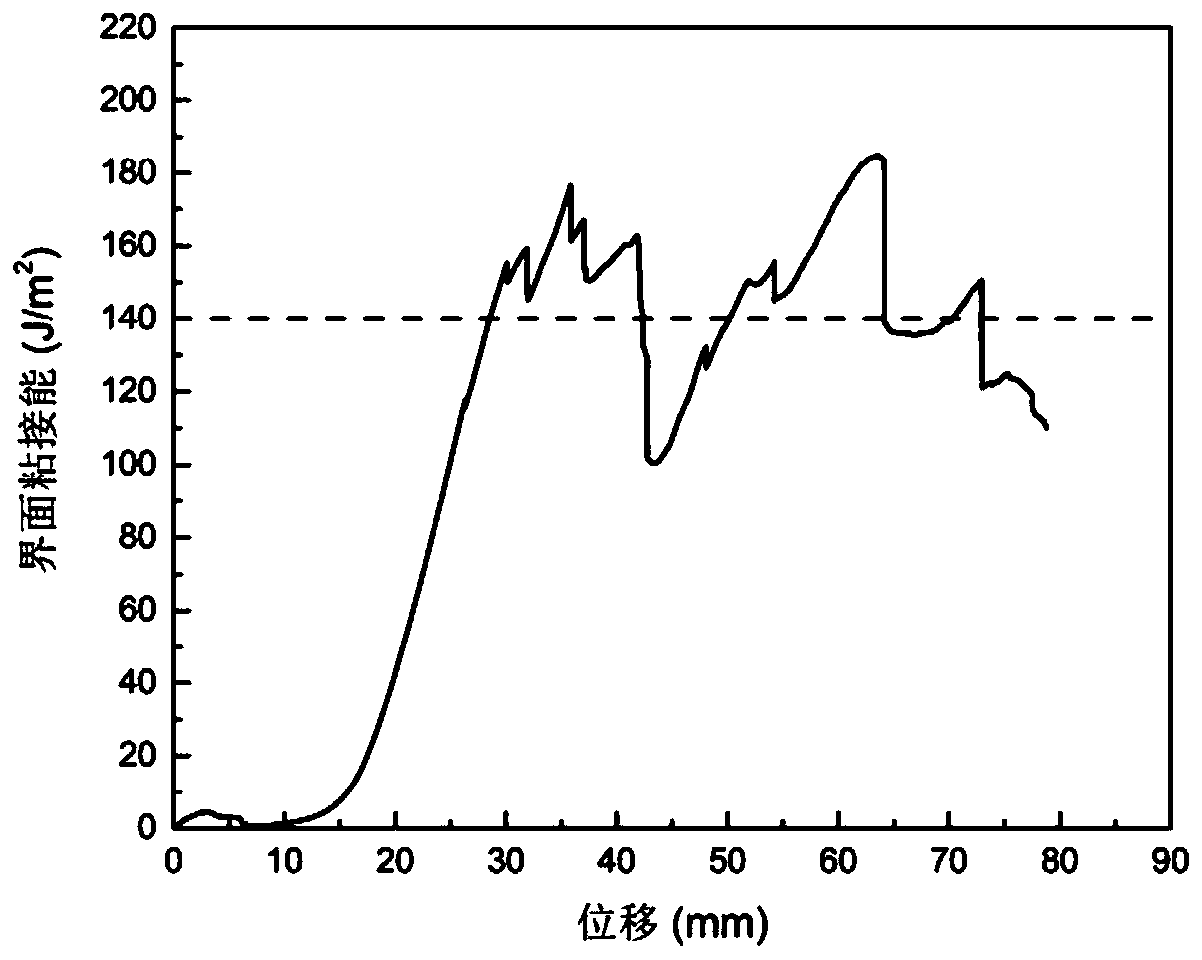

[0081] (1) Coating: Prepare an aqueous solution of acrylamide with a mass fraction of 10%, adjust the pH to 3.5 with acetic acid; then add 0.6% 3-(trimethoxysilyl)propyl methacrylate to the solution As a silane coupling agent, after stirring evenly, it is fully hydrolyzed, and 0.004% of 2-hydroxyl-4'-(2-hydroxyethoxyl)-2-methylpropiophenone is added to the solution as an initiator, Stir evenly and inhale into a syringe; place the syringe under ultraviolet light for free radical polymerization for 30 minutes to obtain a hydrogel primer coating solution with a dynamic viscosity of 7.8 Pa s; prepare an aqueous solution of acrylamide with a mass fraction of 15%, Add methylenebisacrylamide with acrylamide molar mass ratio of 1:400 to the solution as a cross-linking agent, then add 0.01% α-ketoglutaric ac...

Embodiment 2

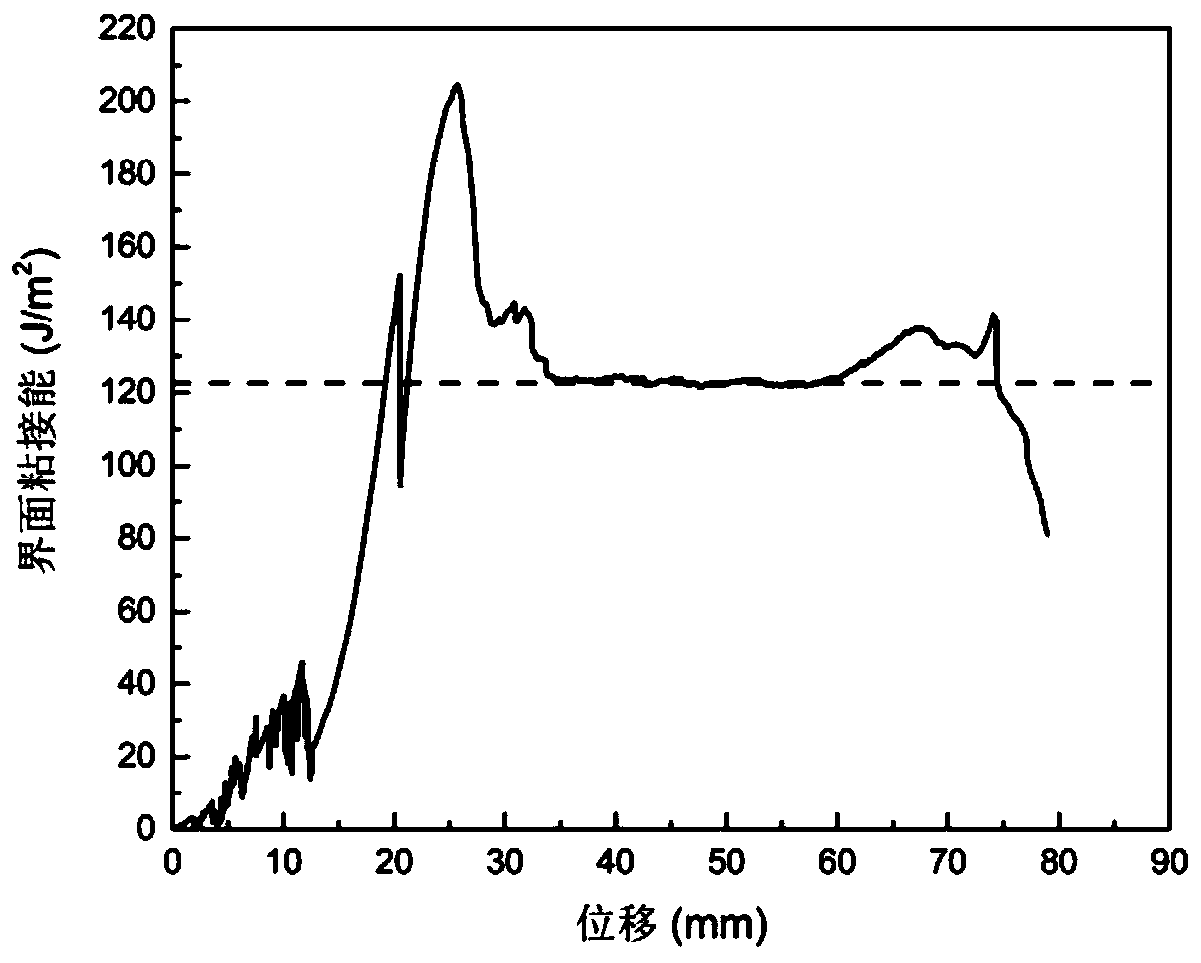

[0085] This embodiment provides a method for combining polyacrylic acid hydrogel and polyurethane elastomer for strong bonding, and its preparation method is as follows:

[0086] (1) Coating: prepare an aqueous solution of acrylic acid with a mass fraction of 15%, adjust the pH to 3.5 with sodium hydroxide; then add (trimethylsilyl) methacrylate with a mass fraction of 0.8% to the solution as a silane coupling After stirring evenly, when it is fully hydrolyzed, add α-ketoglutaric acid with a mass fraction of 0.01% into the solution as an initiator, stir well and suck it into a syringe; place the syringe under ultraviolet light for free radical polymerization for 30 minutes , to obtain a hydrogel primer coating solution with a dynamic viscosity of 9.2Pa s; to prepare an aqueous acrylic acid solution with a mass fraction of 15%, and then add methylenebisacrylamide with acrylamide molar mass ratio of 1:300 in the solution As a cross-linking agent, α-ketoglutaric acid with a mass ...

Embodiment 3

[0090] This embodiment provides a bonding method for polyacrylamide hydrogel and polydimethylsiloxane elastomer. The difference between the bonding method and Example 1 is that in step (1), the hydrogel bottom During the preparation of the paint coating solution, acrylic acid aqueous solution with a mass fraction of 30% was configured, and other preparation steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com