NbMoTaWAl refractory high-entropy alloy film and preparation method thereof

A technology of high-entropy alloy and thin film, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems that the mechanical properties cannot meet the requirements of use, and achieve the improvement of mechanical properties and oxidation resistance, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

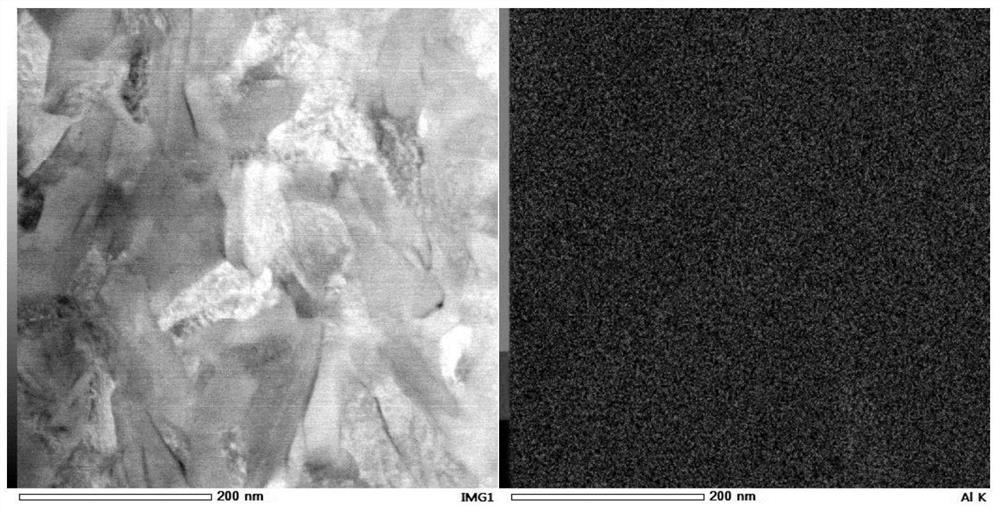

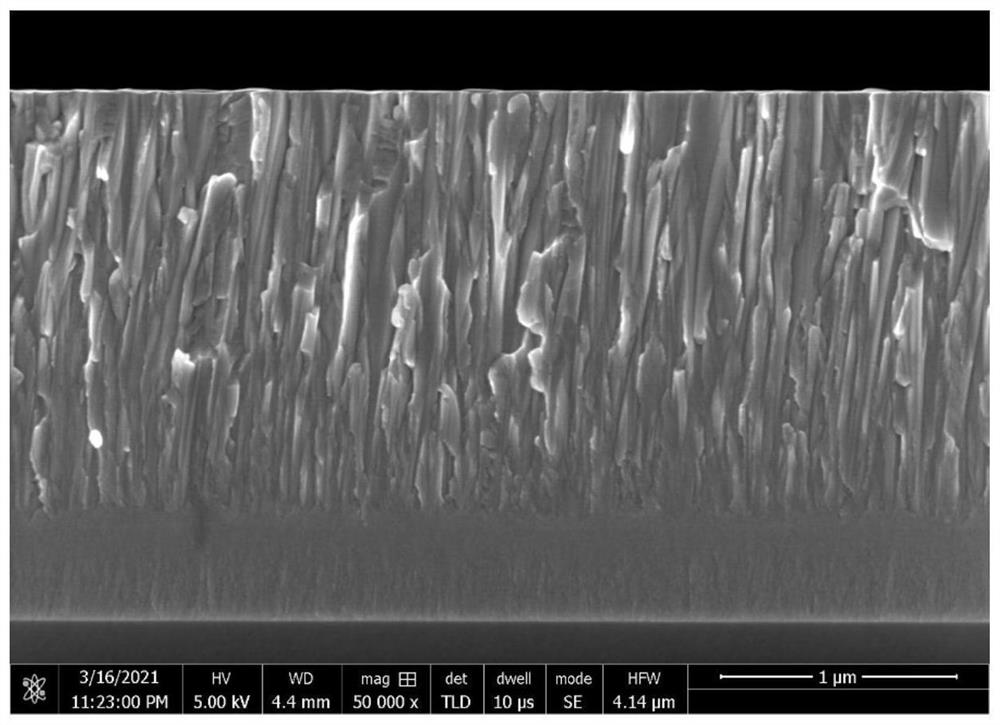

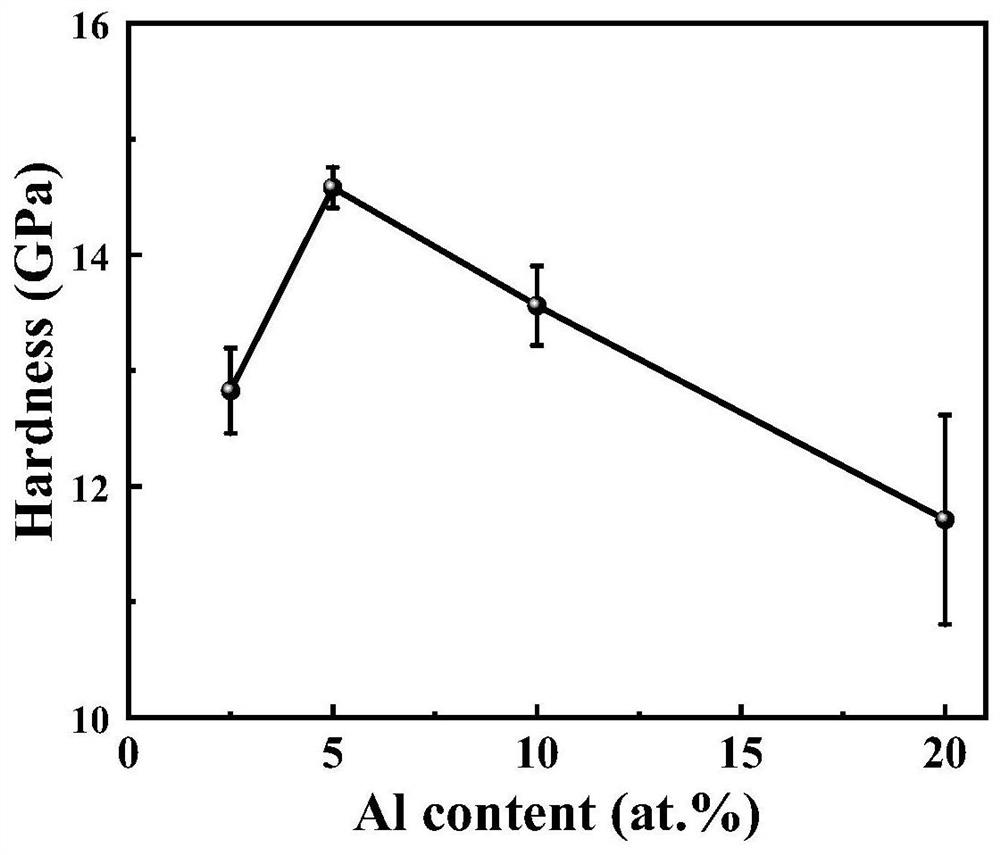

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing a NbMoTaWAl refractory high-entropy alloy film, comprising the following steps:

[0032] Step 1: Take the monocrystalline silicon substrate polished on one side, ultrasonically clean it in acetone and ethanol for 10 minutes, and then dry it to ensure that the surface of the substrate is clean and free of stains and dust. The surface roughness of the monocrystalline silicon substrate after ultrasonic cleaning is less than 0.8 nm, ultrasonic cleaning of the polished single crystal silicon substrate is beneficial to improve the bonding force between the film and the substrate.

[0033] Step 2: Fix the single-crystal silicon substrate after ultrasonic cleaning to the substrate, and send it into the magnetron sputtering coating chamber with automatic machinery, and vacuumize until the vacuum degree of the back and bottom is 4.0×10 -4 Below Pa, at Ar + Etching was carried out for 5 min under atmosphere, and the etchi...

Embodiment 1

[0039] Step 1: The single-crystal silicon substrate polished on one side is ultrasonically cleaned in acetone and ethanol for 10 minutes, and dried with a hair dryer.

[0040] Step 2: Fix the substrate on the substrate, and then mechanically and automatically send it into the vacuum coating chamber. Before deposition, the vacuum degree of the background should be lower than 4.0×10 -4 Pa, and etch for 5min, and the etching power is 200W.

[0041] Step 3: NbMoTaWAl refractory high-entropy alloy film was prepared by co-sputtering by magnetron sputtering.

[0042]Among them, the NbMoTaW alloy target with a purity of 99.9wt.% (Nb:Mo:Ta:W=1:1:1:1at.%) adopts a DC power supply with a power of 200W, and the Al target with a purity of 99.99wt.% adopts a radio frequency power supply with a power of 13W, the working pressure setting is 0.3Pa, the deposition temperature is 150°C, the substrate rotation speed is 15r / min, and the total deposition time is 10000s.

[0043] Step 4: After the...

Embodiment 2

[0046] Step 1: The single-crystal silicon substrate polished on one side is ultrasonically cleaned in acetone and ethanol for 10 minutes, and dried with a hair dryer.

[0047] Step 2: Fix the substrate on the substrate, and then mechanically and automatically send it into the vacuum coating chamber. Before deposition, the vacuum degree of the background should be lower than 4.0×10 -4 Pa, and etch for 5min, and the etching power is 200W.

[0048] Step 3: NbMoTaWAl refractory high-entropy alloy film was prepared by co-sputtering by magnetron sputtering.

[0049] Among them, the NbMoTaW alloy target with a purity of 99.9wt.% (Nb:Mo:Ta:W=1:1:1:1at.%) adopts a DC power supply with a power of 200W, and the Al target with a purity of 99.99wt.% adopts a radio frequency power supply with a power of 33W, the set value of the working pressure is 0.3Pa, the deposition temperature is 150°C, the rotation speed of the substrate is 15r / min, and the total deposition time is 10000s.

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com