Flexible electronic device and manufacturing method therefor

A flexible electronic device and a flexible technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of electrical performance and anti-kneading performance of electronic devices, and achieve the effect of ensuring electrical performance and anti-kneading performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

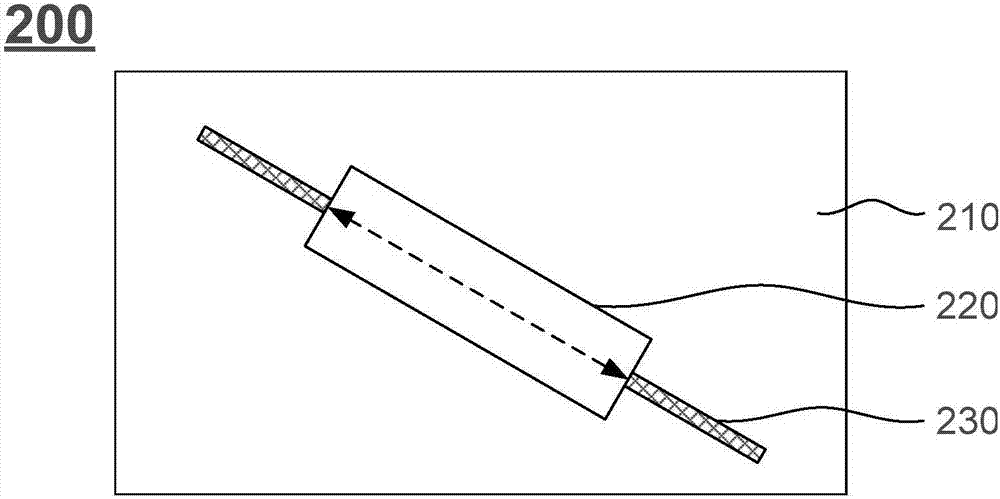

[0034] Please refer to image 3 , which is a schematic structural diagram of a flexible electronic device according to an embodiment of the present invention. Such as image 3 As shown, the flexible electronic device 200 includes: a flexible substrate 210 and a device layer formed on the flexible substrate 210; the device layer includes an interconnected semiconductor structure 220 and a first wire structure 230, and the first The extension direction of the wire structure 230 is consistent with the channel direction of the semiconductor structure 220 ; the extension direction of the first wire structure 230 and the stretching direction of the flexible substrate 210 form an angle less than 90°. The semiconductor structure in the embodiment of the present invention is a thin film transistor structure, specifically including a gate, a drain (not shown in the figure), and a channel.

[0035] Specifically, in the flexible electronic device 200, the device layer includes an interc...

Embodiment 2

[0049] Please refer to Figure 5 , which is a schematic structural diagram of a flexible electronic device according to Embodiment 2 of the present invention. Such as Figure 5 As shown, the flexible electronic device 300 includes: a flexible substrate 310 and a device layer 330 formed on the flexible substrate 310; the device layer 330 includes interconnected semiconductor structures (not shown in the figure) and a first A wire structure (not shown in the figure), the extension direction of the first wire structure is consistent with the channel direction of the semiconductor structure; the extension direction of the first wire structure is formed with the stretching direction of the flexible substrate 310 Angles less than 90°.

[0050] Specifically, in the flexible electronic device 300, the device layer 330 includes a plurality of pixel units 30 and a first wire structure, the plurality of pixel units 30 are arranged in an array, and each pixel unit 30 has a switch functi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com