Heat treatment method for amorphous material or nanocrystalline material for magnetic shield sheet

A technology of nanocrystalline material and heat treatment method, which is applied in the field of heat treatment of amorphous or nanocrystalline materials, can solve the problems that the electromagnetic properties of amorphous and nanocrystalline materials cannot be fully exerted, the magnetic permeability is not high, and the magnetic permeability is decreased. Achieve the effect of improving charging efficiency, increasing magnetic permeability, and reducing saturation magnetostriction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings. The following examples do not limit the invention. Without departing from the spirit and scope of the inventive concept, changes and advantages that can be imagined by those skilled in the art are all included in the present invention.

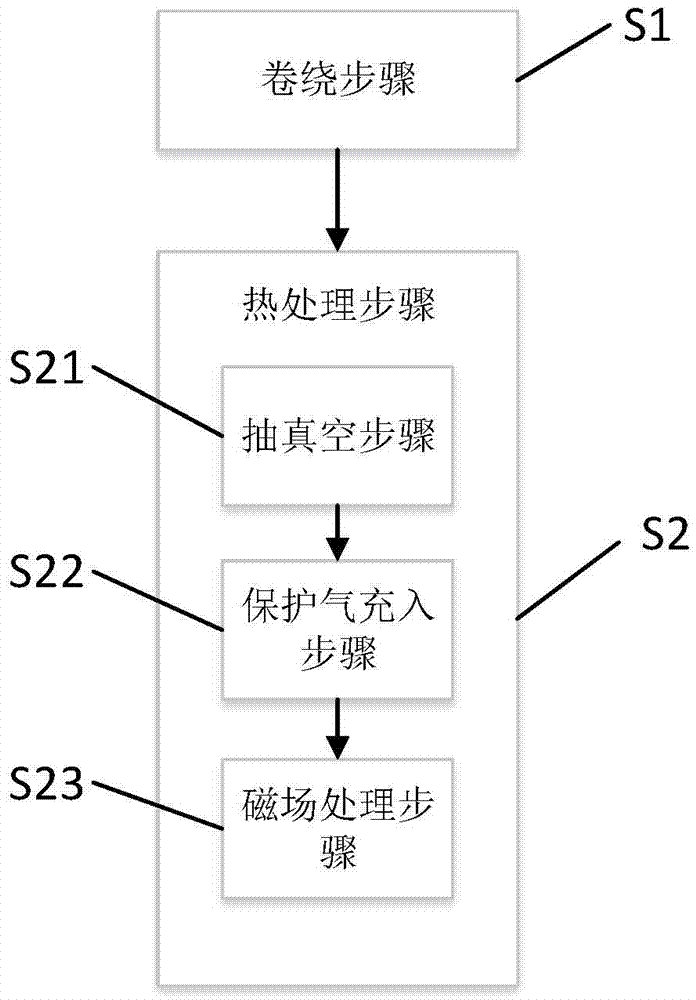

[0027] like figure 1 Shown, the heat treatment method of the amorphous or nanocrystalline material that is used for magnetic shield sheet of the present invention, comprises the steps:

[0028] In the winding step (S1), the amorphous material or the nanocrystalline ribbon is wound into a magnetic core of required size. In the embodiment of the present invention, the amorphous strip material is 1K101 material, and the nanocrystalline strip material is 1K107 material.

[0029] In the heat treatment step (S2), the amorphous or nanocrystalline magnetic cores are arranged according to certain rules and placed in a heat treatment furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com