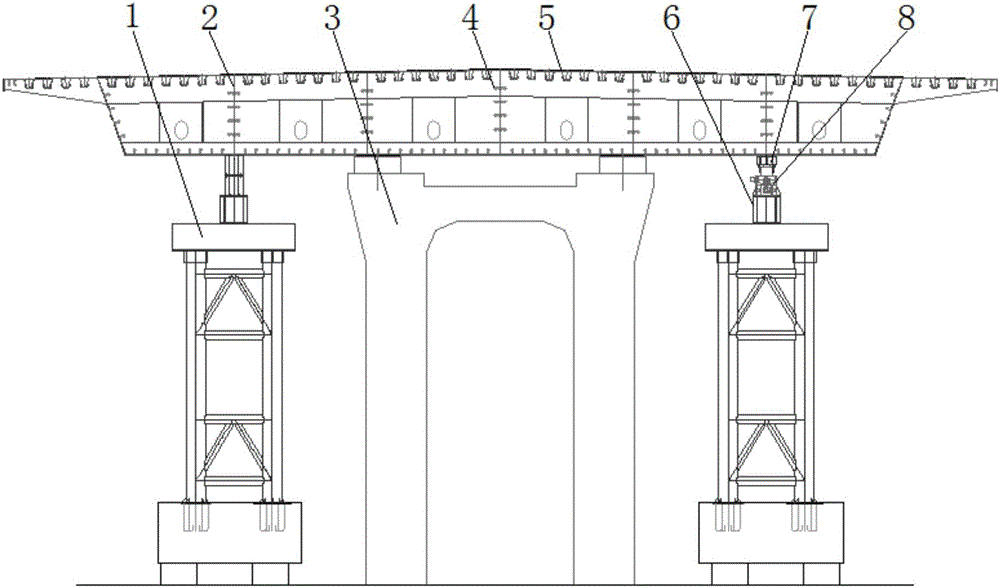

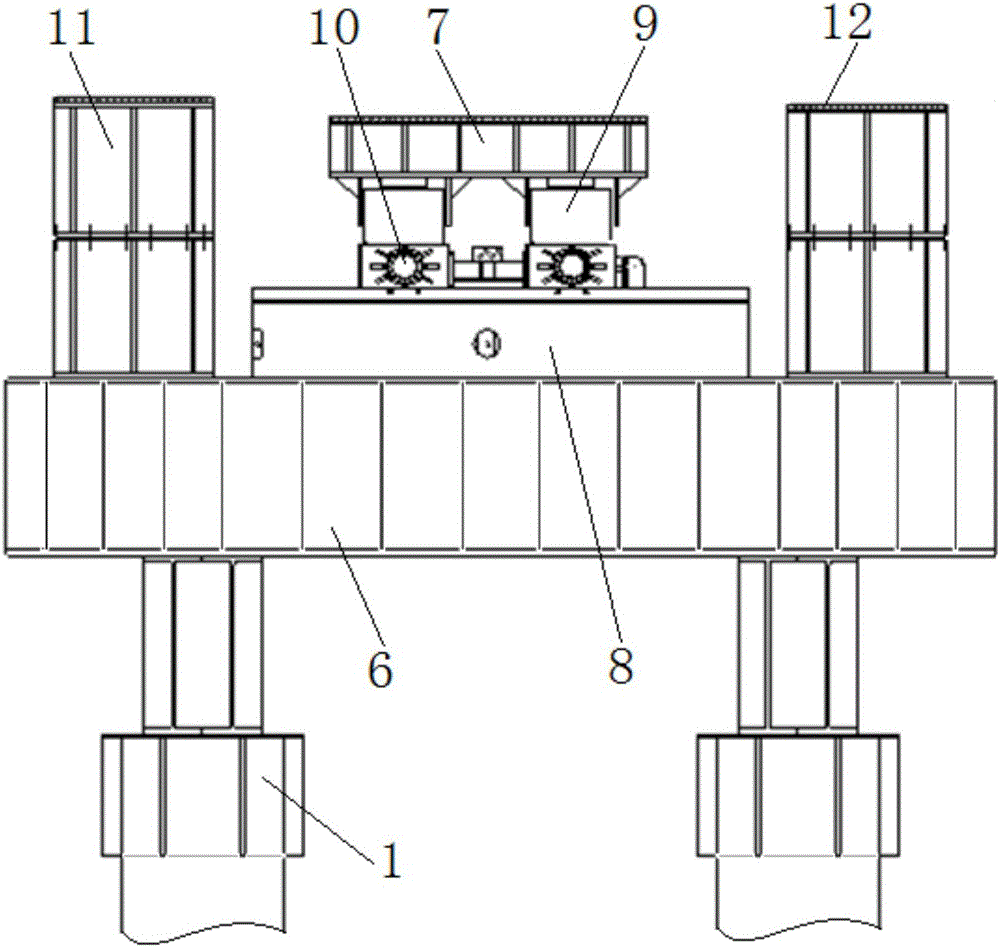

Steel box beam pushing and deviation correcting method for walking type multiple-point continuous pushing technique

A walking-type, steel box girder technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as steel box girder tilt and lateral offset, out-of-tolerance, and out-of-synchronization of jacking equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

[0031] The steel box girder jacking and deflection correction method of the walking multi-point continuous jacking process provided by the present invention performs vertical jacking control during the jacking and falling process of the steel box girder, and performs synchronous jacking control and correction during the translation process of the steel box girder. Central axis deviation correction control runs through balance degree control and cumulative error control throughout the pushing process, using pressure sensors, displacement sensors and photoelectric switches for color difference detection to monitor and detect the steel box girder pushing pressure and the deviation distance of the central axis during the pushing process in real time , the details are as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com