Hydrotalcite and bismuth molybdate heterojunction composite photocatalyst as well as preparation method and application thereof

A technology of bismuth molybdate and heterojunction, which is applied in the field of photocatalysis, can solve the problems of low electron-hole separation rate, high recombination rate, no photocatalytic activity and poor effect of photocatalyst, so as to improve the recombination rate and separation. Degree, uniform distribution, full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

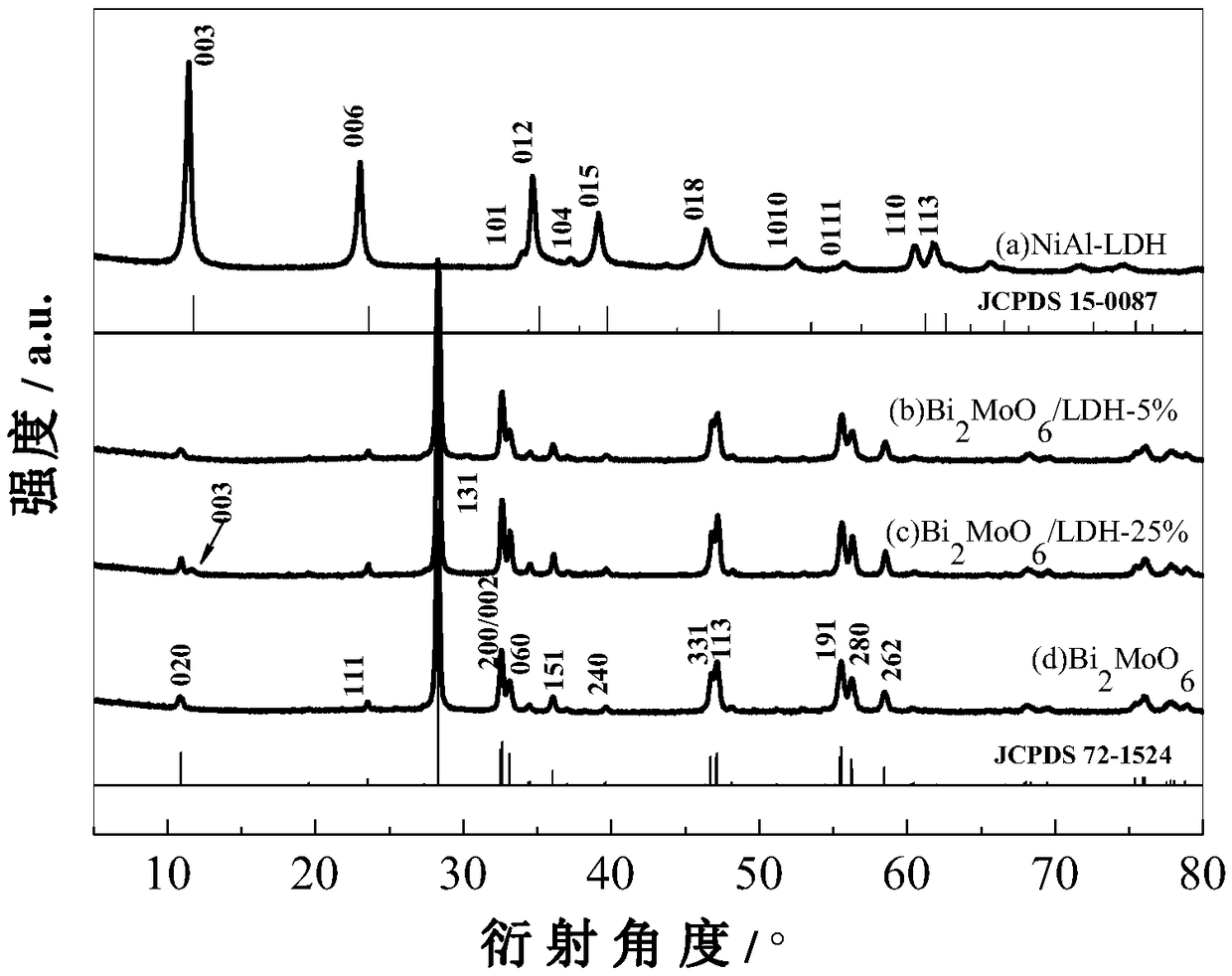

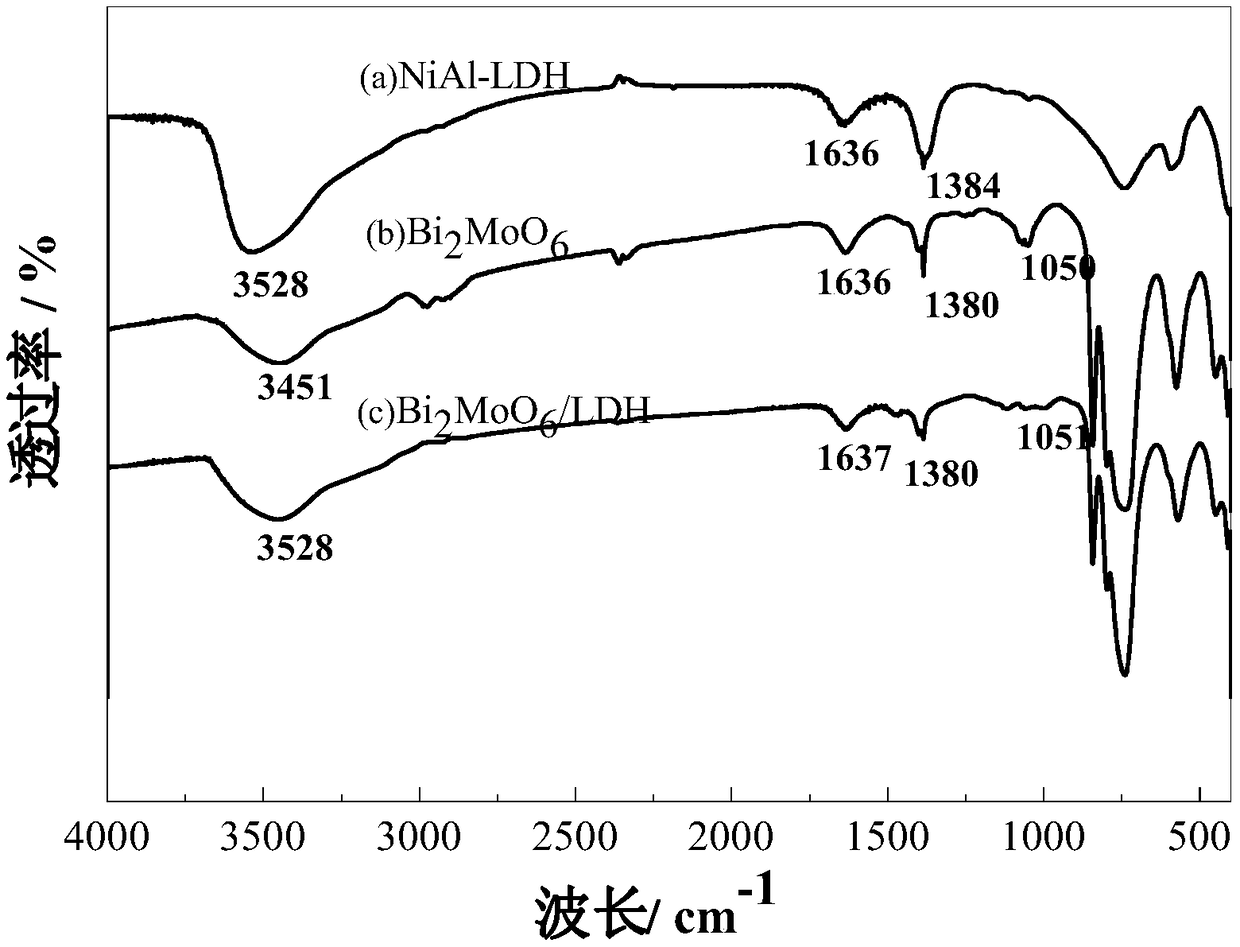

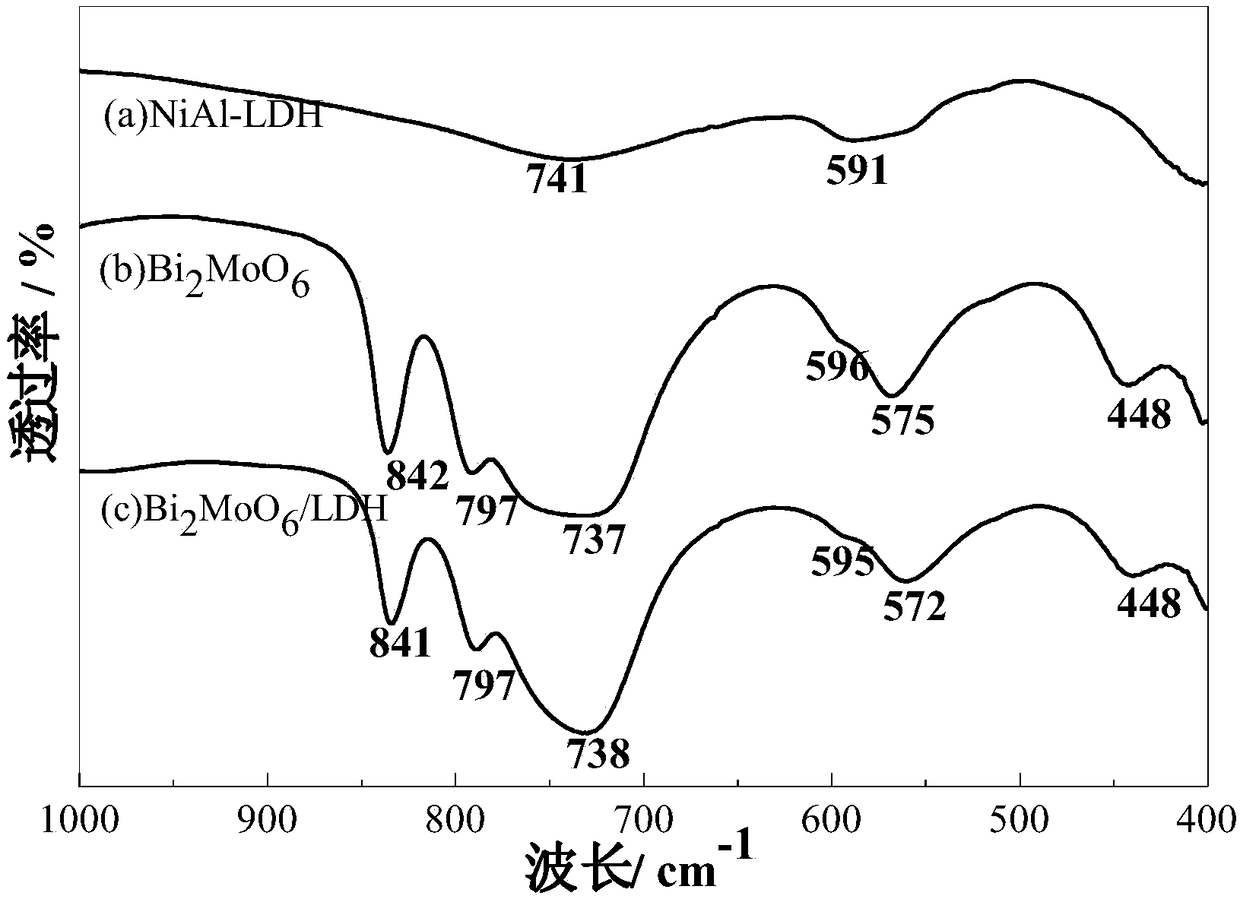

[0039] Step (1) synthesis of Bi 2MoO 6

[0040] Weigh 6mmol Bi(NO 3 ) 3 ·5H 2 O, 3 mmol Na 2 MoO 4 2H 2 O into a 100mL beaker, then add 60mL of distilled water and 2mL of HNO 3 Dissolve with magnetic stirring, adjust the pH of the solution to 5 with 2M NaOH solution, stir magnetically at room temperature for 30 min, put it into an 80 mL stainless steel reaction kettle, and heat it in an oven at 180 °C for 24 h. After the reaction, it was naturally cooled to room temperature, centrifuged, washed with distilled water and ethanol, and the sample was placed in a drying oven at 80°C for 12 hours.

[0041] Step (2) synthesizes Bi 2 MoO 6 / NiAl-LDH semiconductor composite material (Bi 2 MoO 6 / LDH-5%)

[0042] Weigh 1.5g Bi 2 MoO 6 Powder, put into a 100mL beaker containing 60mL distilled water and sonicate for 1h. Then, 0.5mmol Ni(NO 3 ) 2 ·6H 2 O, 0.25mmol Al(NO 3 ) 3 9H 2 O, 8 mmol NH 4 F, 15 mmol CH 4 N 2 O was added to a 50mL beaker containing 20mL of di...

Embodiment 2

[0046] Step (1) synthesis of Bi 2 MoO 6

[0047] Weigh 6mmol Bi(NO 3 ) 3 ·5H 2 O, 3 mmol Na 2 MoO 4 2H 2 O into a 100mL beaker, then add 60mL of distilled water and 2mL of HNO 3 Dissolve with magnetic stirring, adjust the pH of the solution to 5 with 2M NaOH solution, stir magnetically at room temperature for 30 min, put it into an 80 mL stainless steel reaction kettle, and heat it in an oven at 180 °C for 24 h. After the reaction, it was naturally cooled to room temperature, centrifuged, washed with distilled water and ethanol, and the sample was placed in a drying oven at 80°C for 12 hours.

[0048] Step (2) synthesizes Bi 2 MoO 6 / NiAl-LDH semiconductor composite material (Bi 2 MoO 6 / LDH-10%)

[0049] Weigh 1.5g Bi 2 MoO 6 Powder, put into a 100mL beaker containing 60mL distilled water and sonicate for 1h. Then, 1mmol Ni(NO 3 ) 2 ·6H 2 O, 0.5mmol Al(NO 3 ) 3 9H 2 O, 8 mmol NH 4 F, 15 mmol CH 4 N 2 O was added to a 50mL beaker containing 20mL of dis...

Embodiment 3

[0051] Step (1) synthesis of Bi 2 MoO 6

[0052] Weigh 6mmol Bi(NO 3 ) 3 ·5H 2 O, 3 mmol Na 2 MoO 4 2H 2 O into a 100mL beaker, then add 60mL of distilled water and 2mL of HNO 3 Dissolve with magnetic stirring, adjust the pH of the solution to 5 with 2M NaOH solution, stir magnetically at room temperature for 30 min, put it into an 80 mL stainless steel reaction kettle, and heat it in an oven at 180 °C for 24 h. After the reaction, it was naturally cooled to room temperature, centrifuged, washed with distilled water and ethanol, and the sample was placed in a drying oven at 80°C for 12 hours.

[0053] Step (2) synthesizes Bi 2 MoO 6 / NiAl-LDH semiconductor composite material (Bi 2 MoO 6 / LDH-15%)

[0054] Weigh 1.5g Bi 2 MoO 6 Powder, put into a 100mL beaker containing 60mL distilled water and sonicate for 1h. Then, 1.5mmol Ni(NO 3 ) 2 ·6H 2 O, 0.75mmol Al(NO 3 ) 3 9H 2 O, 8 mmol NH 4 F, 15 mmol CH 4 N 2 O was added to a 50mL beaker containing 20mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com