LED quantum well structure, manufacture method of the same, and LED epitaxial wafer comprising the same

A technology of LED epitaxial wafers and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems of low growth temperature of InGaN layers, large polarization effects, and large internal stress of quantum well structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

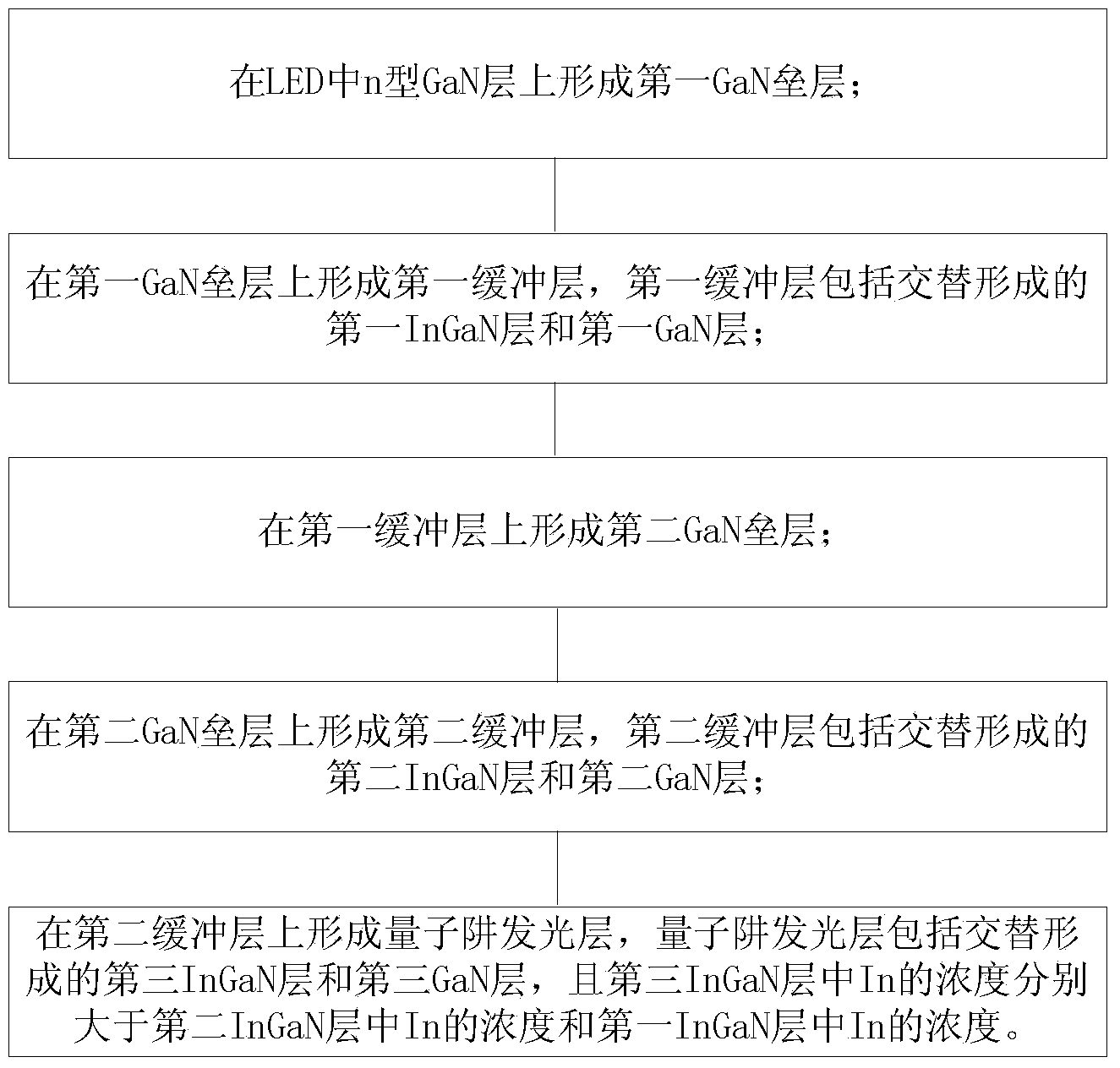

[0065] This embodiment provides a method for manufacturing an LED epitaxial wafer, comprising the following steps:

[0066] Forming a GaN buffer layer, u-type GaN, and n-type epitaxial layer includes the following steps: placing the sapphire substrate in an MOCVD reaction chamber, and feeding 100 standard liters / min of high-purity H at a temperature of 1100°C 2 Process the sapphire substrate for 20 minutes; lower the temperature to 570°C, grow a GaN buffer layer with a thickness of 45nm on the sapphire substrate; raise the temperature to 1150°C, grow a 2.5μm u-type GaN layer on the GaN buffer layer; cool down to 1000 ℃, grow a 100nm AlGaN layer on the u-type GaN layer; raise the temperature to 1130 °C, grow a 3.5 μm Si-doped n-type GaN layer on the AlGaN layer, where the doping concentration of Si is 1.5E19atom / cm 3 ;

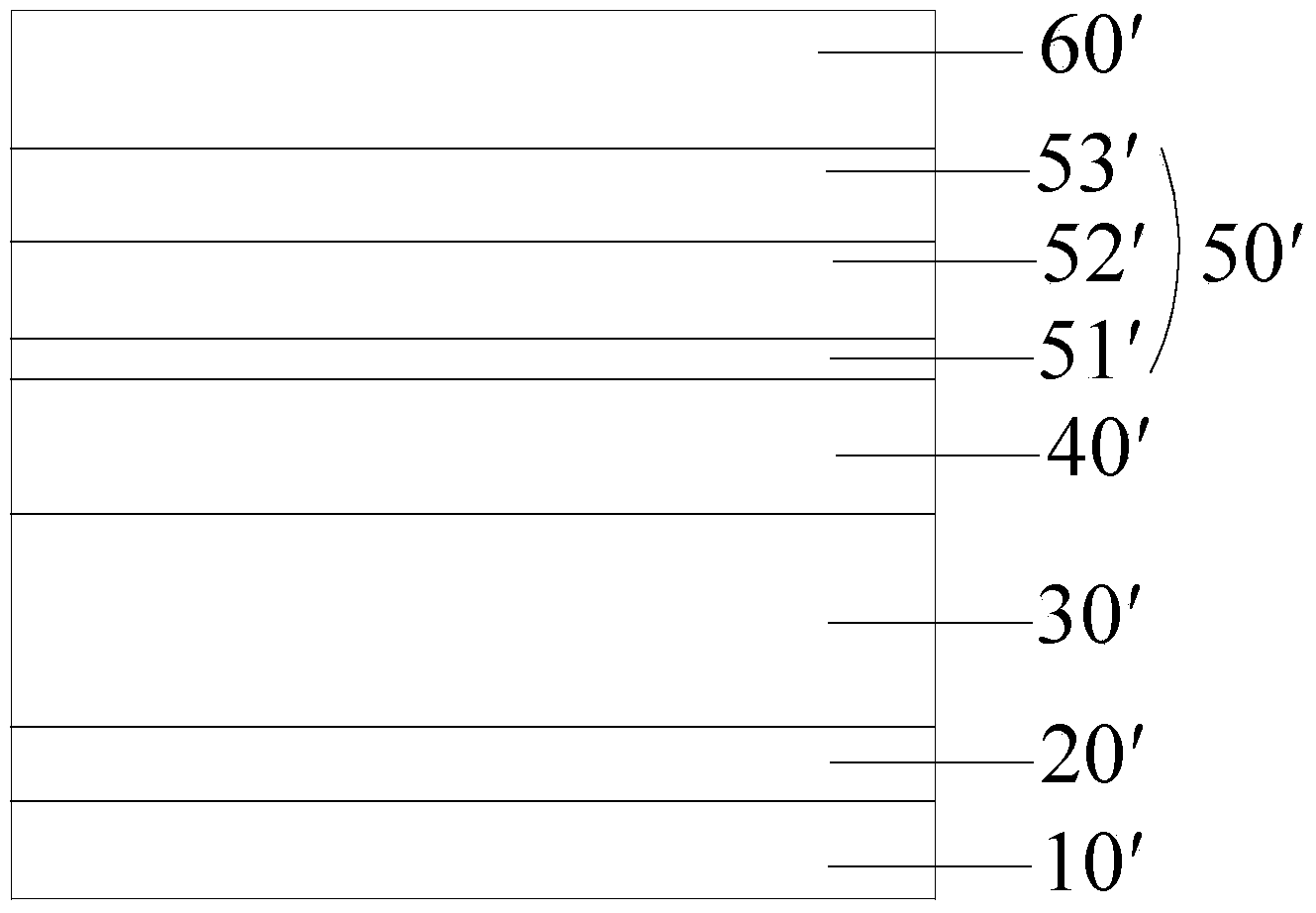

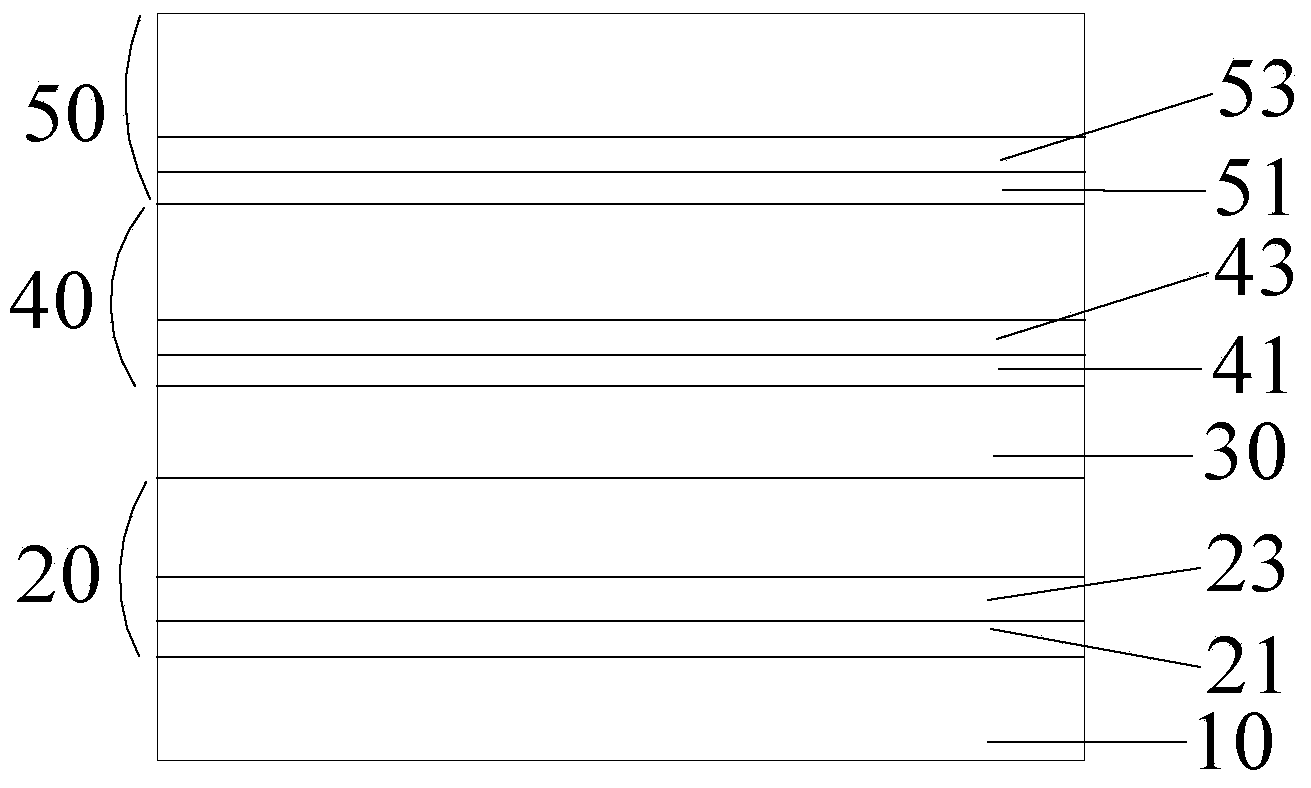

[0067] Forming the quantum well structure includes the following steps: lower the temperature to 900°C, and grow a first GaN barrier layer with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com