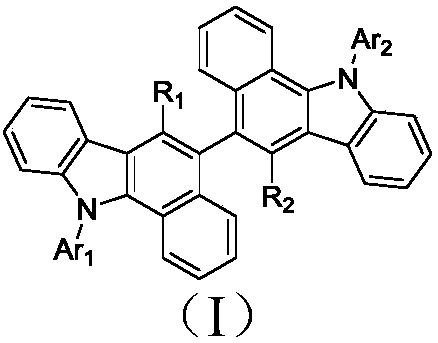

Benzo-carbazole compound and organic light-emitting device thereof

An organic light-emitting device, benzocarbazole technology, applied in the field of organic optoelectronic materials to achieve the effect of improving carrier injection balance and improving recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

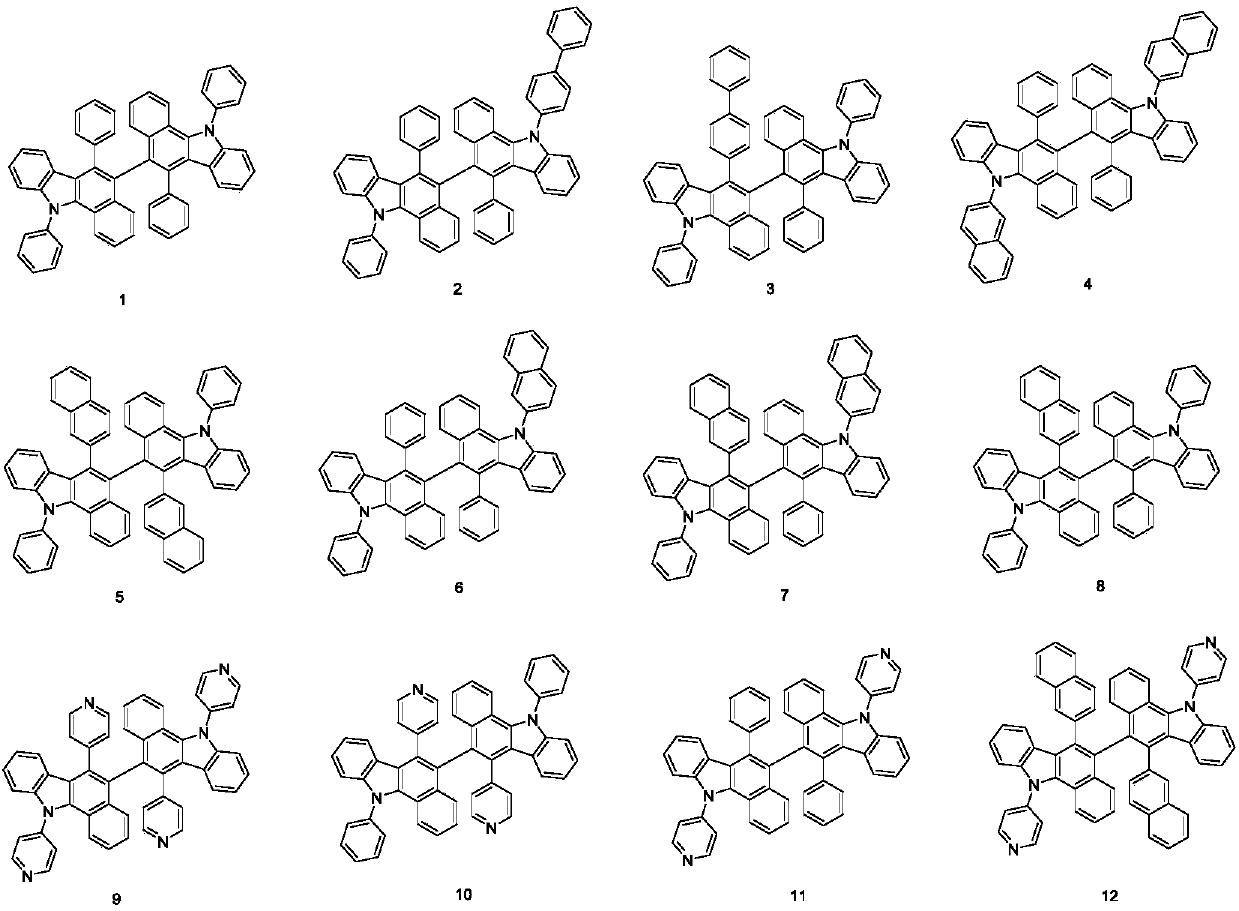

Examples

Embodiment 1

[0037] Example 1: Preparation of Compound 1

[0038] Preparation of Intermediate 1-A:

[0039]

[0040] Weigh compound 1-a (30.6g, 251mmol), compound 1-b (103.38g, 251mmol), tetrakistriphenylphosphine palladium (11g, 10mmol) and potassium carbonate (84.2g, 609mmol), and weigh the reaction The substance was dissolved in a solvent of toluene (1L) / EtOH (200mL) / distilled water (200mL), heated at 90°C for 2 hours, several layers were distilled under reduced pressure and then pulverized with methanol. The obtained solid was dissolved in dichloromethane and filtered through silica gel. , Pulverized with dichloromethane and hexane to obtain compound 1-c (72.70, 80%).

[0041] Compound 1-c (13.61g, 37.6mmol) was dissolved in tetrahydrofuran (140mL), hexane solvent and 2.5M n-butyllithium (18mL, 45.1mmol) were added dropwise at -78°C, followed by stirring for 1 hour. After adding trimethyl borate (13 mL, 56.4 mmol) slowly, the mixture was stirred for 2 h. Then 2M hydrochloric acid was added...

Embodiment 2

[0054] Example 2: Preparation of Compound 5

[0055] Preparation of Intermediate 5-B:

[0056]

[0057] The synthesis steps are the same as those of Intermediate 1-B, except that one of the raw materials is replaced with 1-g with 5-g.

[0058] Preparation of compound 5:

[0059]

[0060] The synthesis procedure is the same as that of compound 1, except that the raw materials 1-B and 1-h are replaced with 5-B and 5-h.

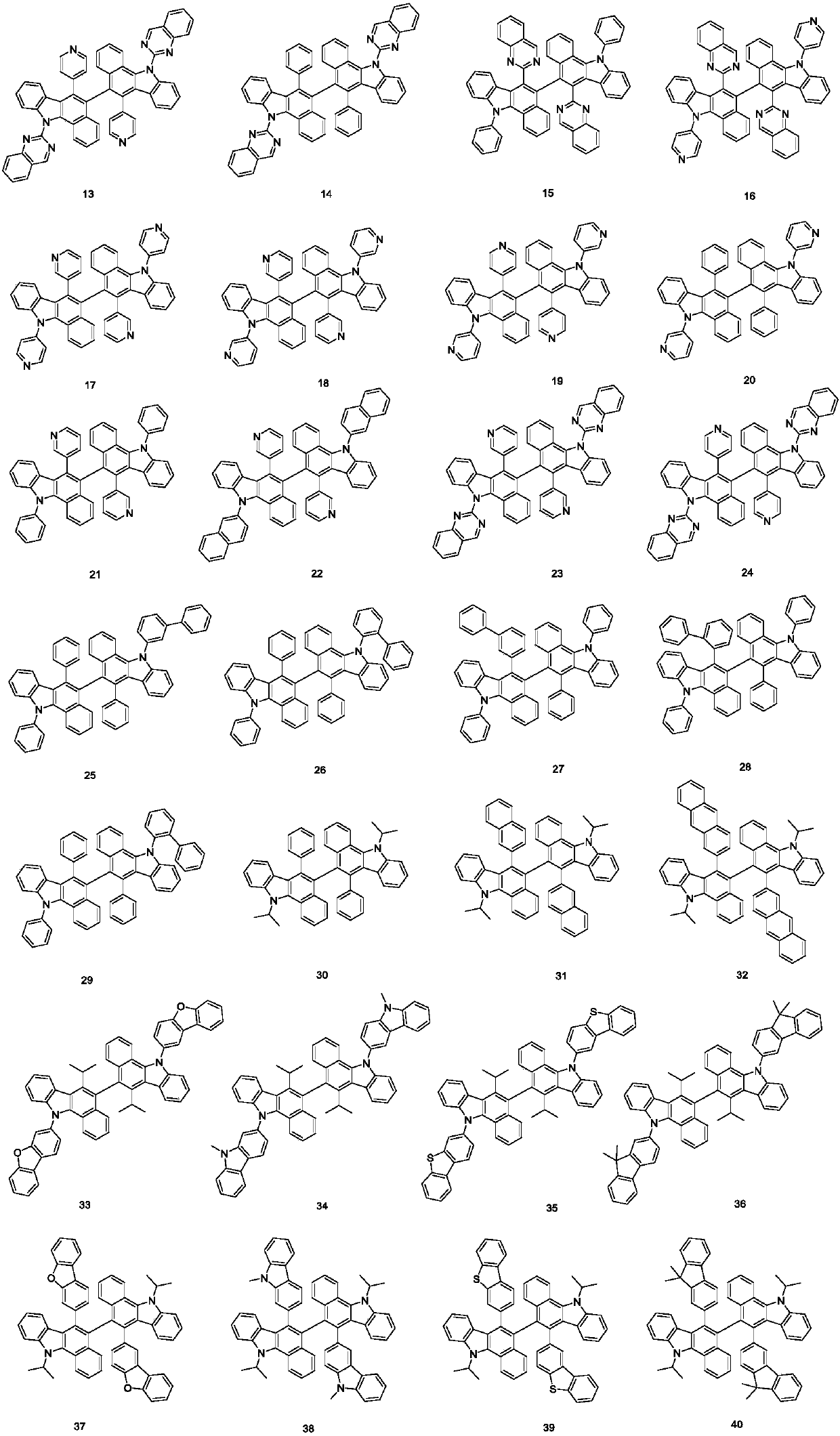

Embodiment 4

[0061] Example 4: Preparation of Compound 9

[0062] Preparation of Intermediate 9-A:

[0063]

[0064] The synthesis procedure is the same as that of Intermediate 1-A, except that the raw material 1-a is replaced with 9-a.

[0065] Preparation of Intermediate 9-B:

[0066]

[0067] The synthesis procedure is the same as that of Intermediate 1-B, except that the raw materials 1-A and 1-g are replaced with 9-A and 9-g.

[0068] Preparation of compound 9:

[0069]

[0070] The synthesis procedure is the same as that of compound 1, except that the raw materials 1-B and 1-h are replaced with 9-B and 9-h.

[0071] Example 4: Preparation of Compound 10

[0072] Preparation of Intermediate 10-B:

[0073]

[0074] The synthesis steps are the same as those of Intermediate 1-B, except that one of the raw materials is replaced with 1-g for 10-g.

[0075] Preparation of compound 10:

[0076]

[0077] The synthesis procedure is the same as that of compound 1, except that the raw materials 1-B and 1-h are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com