Epitaxial structure of a light emitting diode and its manufacturing method

A technology of light-emitting diodes and epitaxial structures, applied in electrical components, circuits, semiconductor devices, etc., can solve the problem of low carrier mobility, and achieve the effects of improving recombination rate, improving brightness, and enhancing confinement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

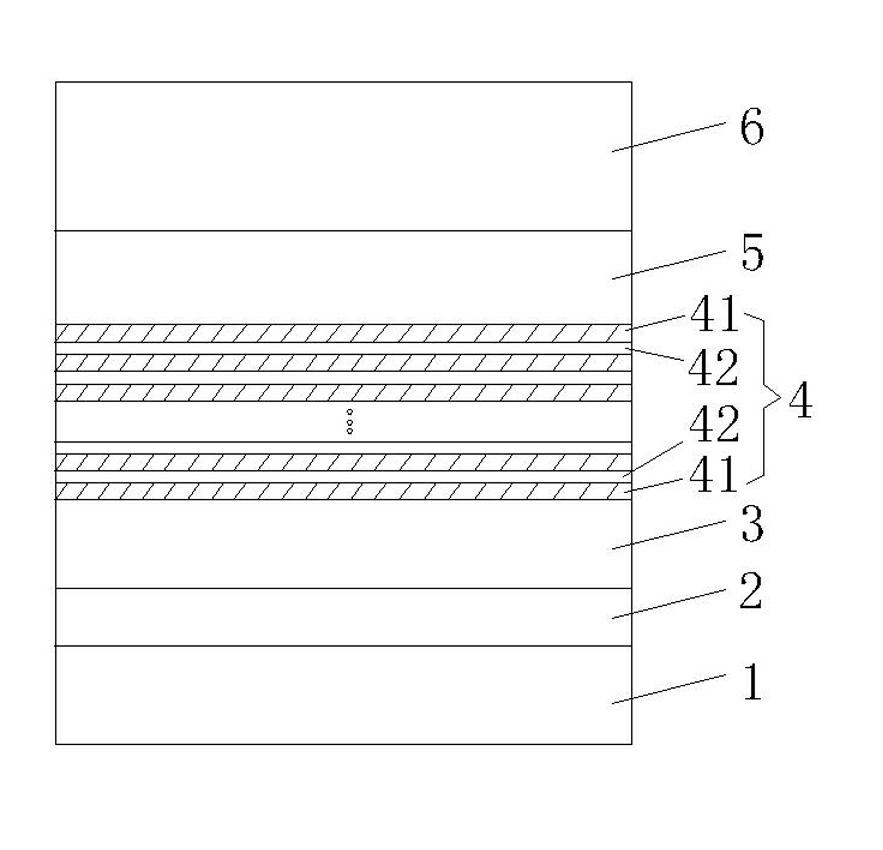

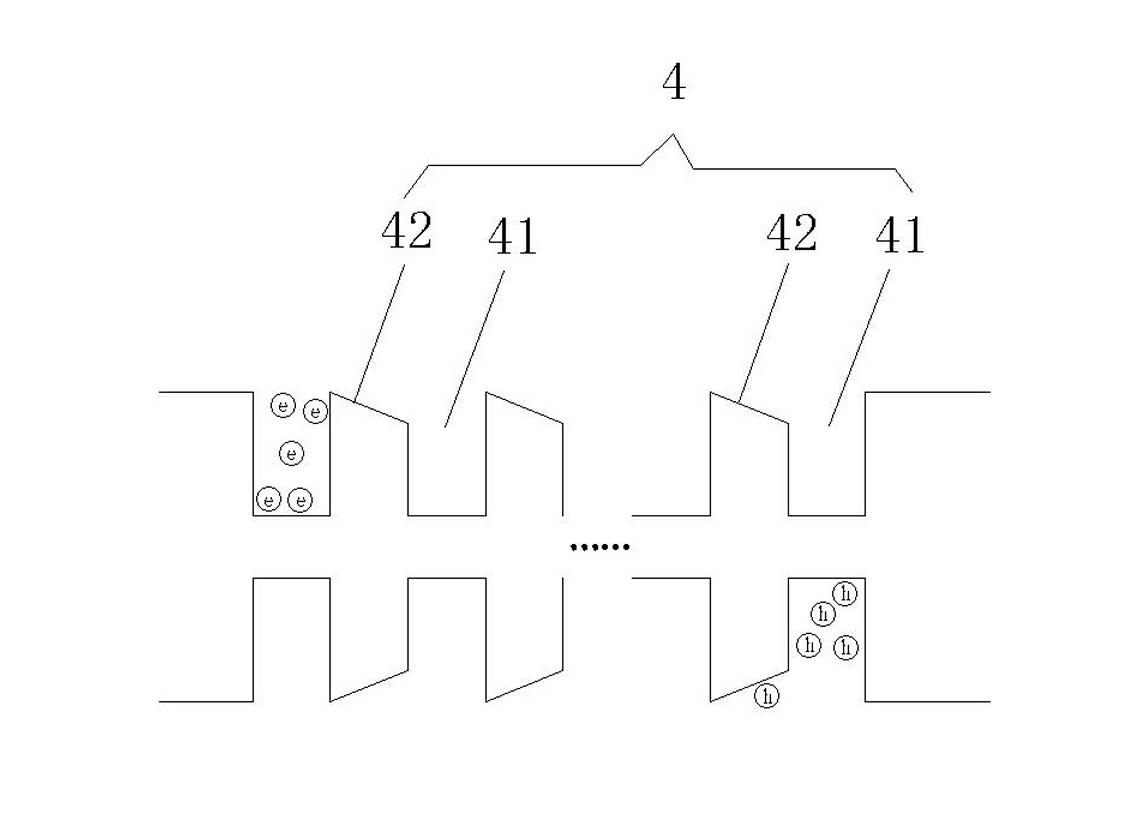

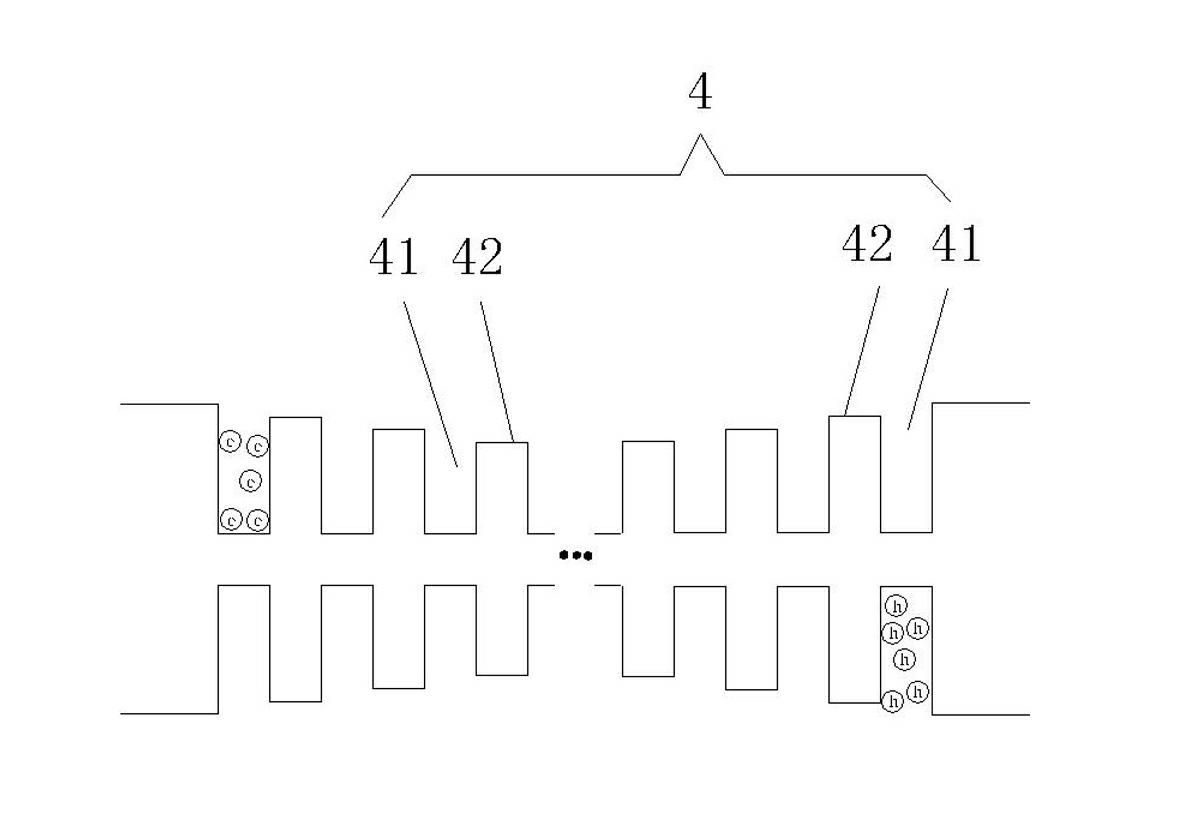

[0024] figure 1 As shown, an epitaxial structure of a light-emitting diode, on top of the GaAs substrate layer 1, there are Bragg reflection layer 2, first-type confinement layer 3, active layer 4, second-type confinement layer 5, and current spreading layer from bottom to top. Layer 6, the active layer 4 is composed of n groups of quantum wells 41 and quantum barriers 42 alternately, wherein the selection range of n is 100≥n≥2, so that the barrier height in the same quantum barrier 42 is a gradual change The distribution or the barrier heights between different quantum barriers 42 is a gradual distribution.

[0025] The above-mentioned epitaxial structure of the light-emitting diode can be manufactured through the following steps:

[0026] 1) Choose GaAs as the substrate layer;

[0027] 2) Growing a Bragg reflection layer on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com