Method for reducing metal impurities in poly(aryl ether ketone) polymer

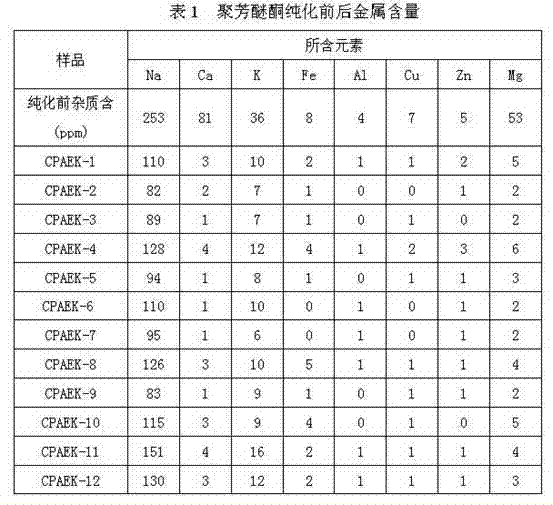

A polyaryletherketone and metal impurity technology is applied in the field of reducing metal impurities in polyaryletherketone, which can solve the problem of high metal impurity content and achieve the effects of reducing metal impurities, reducing content and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 2 g of hydroxyethylidene diphosphonic acid and add it to 400 ml of distilled water to prepare an aqueous solution of hydroxyethylidene diphosphonic acid (mass concentration: 0.5%). Take 130g of pre-crushed polyether ether ketone powder with a particle size of 0.05-0.2mm, put it into a 1000ml three-necked glass bottle, and add the prepared aqueous solution of hydroxyethylidene diphosphonic acid into the three-necked glass bottle. Put the three-neck glass bottle into the heating mantle, install the stirring device, start the stirrer, and start to heat up. When the temperature reached 60°C, the heating was stopped, and after stirring was continued for 1 hour, the aqueous solution was filtered off. Wash the treated material with 500ml of distilled water, wash 2 to 5 times, and check the conductivity of the washing water. When the conductivity is less than 20μS / cm, put the polyether ether ketone powder into the oven, set the temperature at 140°C, and dry After 4 hours,...

Embodiment 2

[0025] According to the method of Example 1, except that the polyether ether ketone was changed to 80 g, after the treatment, a polyarylether ether ketone sample CPAEK-2 with low metal impurity content was obtained.

Embodiment 3

[0027] According to the method of Example 1, except that hydroxyethylidene diphosphonic acid was changed to 3 g (mass concentration: 0.75%), after treatment, a polyaryletherketone sample CPAEK-3 with low metal impurity content was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com