Preparation of low-phosphorus solar-grade polysilicon

A solar-grade, polysilicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high power consumption, pollution, and high cost of chemical methods, and achieve low cost, simple process, and good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

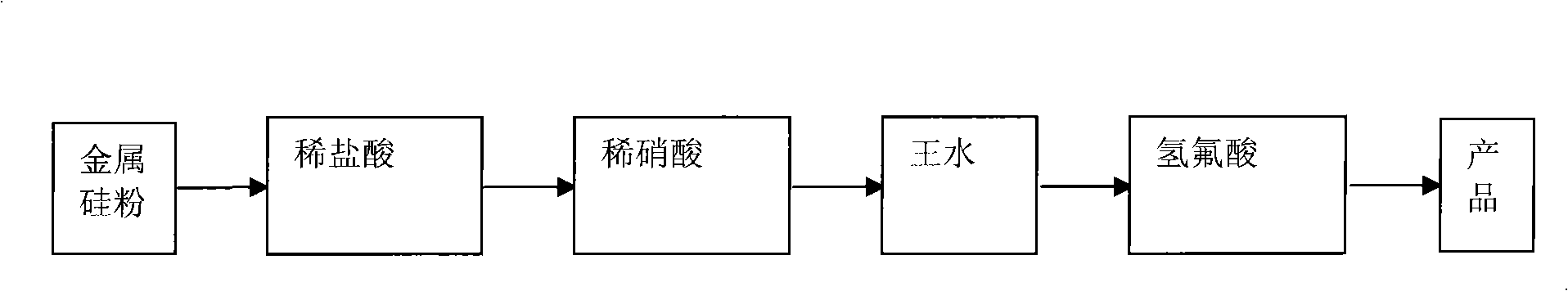

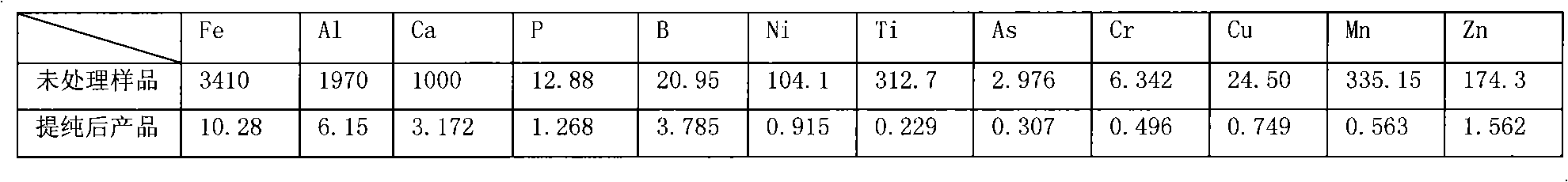

[0014] The preparation method of low-phosphorus solar-grade polysilicon of the present invention, its preferred embodiment is as follows figure 1 As shown, it includes the wet purification of metal silicon powder after phosphorus removal pretreatment and pulverization. The specific wet purification includes treating metal silicon powder with dilute hydrochloric acid, dilute nitric acid, aqua regia, and hydrofluoric acid for 7 to 9 hours respectively. 8 hours of processing time.

[0015] The temperature for wet purification may be 70-90°C, such as 80°C. The particle size of metal silicon powder can be 180-220 mesh, such as 200 mesh.

[0016] When performing wet purification, the concentration of hydrochloric acid can be 3.5-4.5 mol / L, the concentration of nitric acid can be 2.5-3.5 mol / L, and the concentration of hydrofluoric acid can be 0.3-0.4 mol / L. The preferred concentration is: hydrochloric acid 4.0mol / L, nitric acid 3.0mol / L, hydrofluoric acid 0.35mol / L.

[0017] Wet...

specific Embodiment

[0021] Including the high-temperature smelting stage and the wet purification stage, which are described below:

[0022] High temperature melting stage:

[0023] First, the 441# metal silicon block was crushed and ball milled, and the metal silicon powder with a particle size of 200 mesh (about 75 μm) was screened out with a sieve, and 5.000 g was weighed. Then weigh 0.250g of calcium metal, grind it into powder with an agate mortar, and then mix metal silicon powder and metal calcium powder according to m Si :m Ca =20:1 mass ratio fully mixed evenly.

[0024] After that, scoop the evenly mixed powder into an 87.0cm porcelain boat with a plastic medicine spoon, then put it into the middle part of a 21cm×17cm ceramic tube, and then insert the ceramic tube into a tube with a power of 2.5KVA and a furnace size of Φ18×180mm in the electric furnace. Connect the two ends of the ceramic tube with rubber plugs to form a closed environment, and then pass the protective gas high-pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com