Purification method of carbon nano pipe and its device

A technology of carbon nanotubes and purification methods, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of not too thick material layer, limited processing capacity, high energy consumption, etc., to achieve large processing capacity and good purification effect , The effect of high heat transfer/mass transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

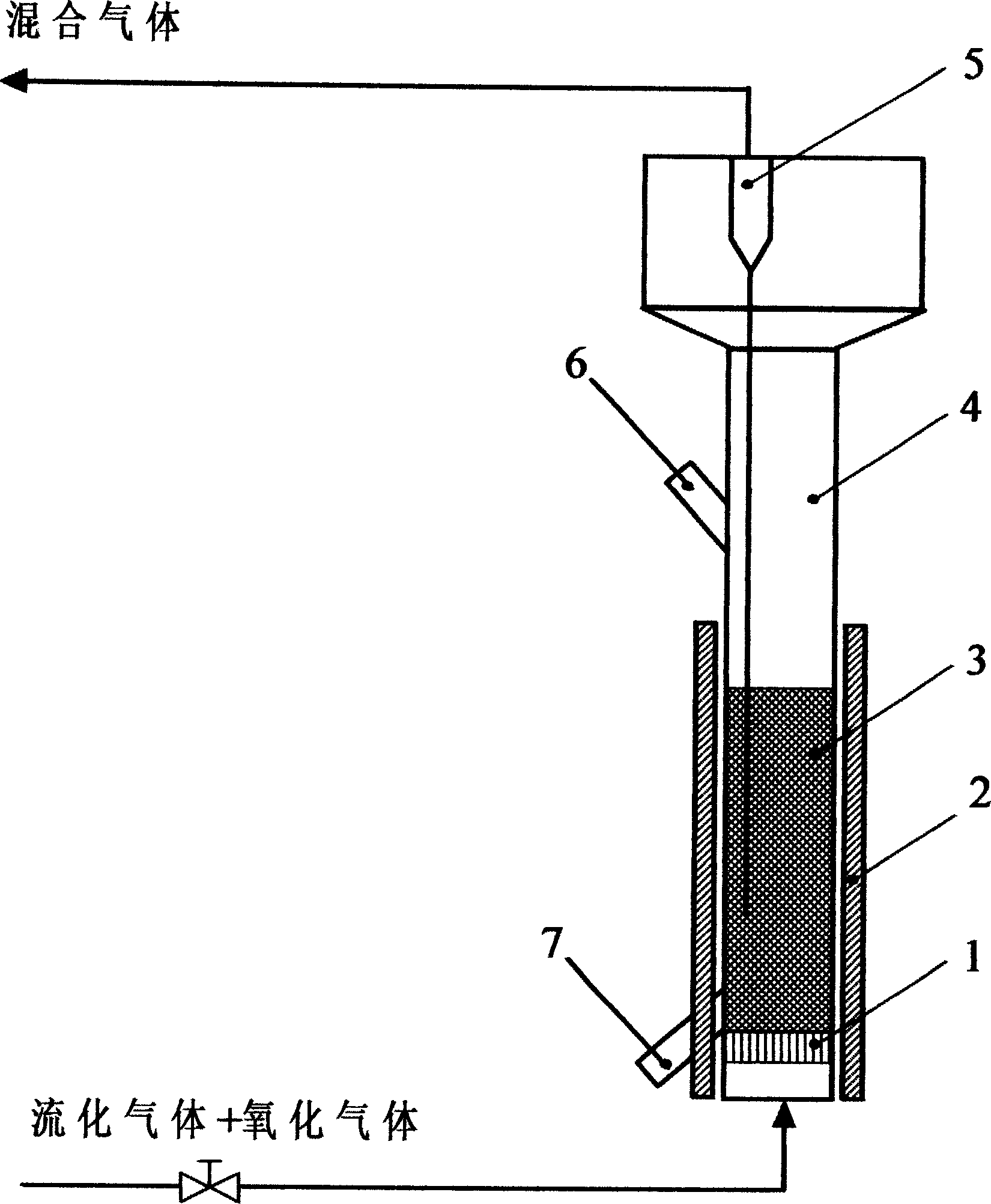

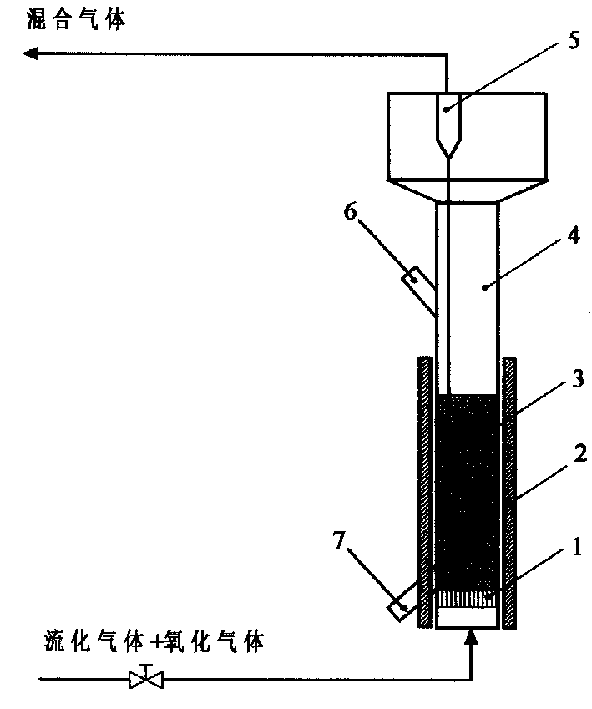

[0011] The invention relates to a method for purifying carbon nanotubes and a device thereof. The structure of its purification device is as follows figure 1 Schematic diagram of the structure of the nano-agglomerated fluidized bed reactor shown. A gas distributor 1 is installed at the bottom of the reactor bed 4, a heating / cooler jacket 2 is set outside the reactor bed 4, a gas-solid separator 5 is installed on the top of the reactor bed 4, and a charging port 6 and the discharge port 7 are installed on the upper and lower sides of the reactor bed 4 respectively.

[0012] The purification method of the above-mentioned carbon nanotubes is to use the impact force of the oxidizing gas and the fluidization gas introduced from the bottom of the nano-agglomeration fluidized bed reactor to stir the solid material 3 in the reactor to make it fully fluidized and selected. Sexual oxidation reaction, the amorphous carbon in the carbon nanotube crude product and the carbon layer coated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com