Preparation method of liraglutide intermediate polypeptide

A technology for intermediates and inclusion bodies, applied in the field of polypeptide preparation, can solve the problems of long time for dissolution and renaturation of inclusion bodies, low intracellular soluble expression and expression, and is not suitable for large-scale production, and achieves less impurities and is conducive to industrialization. Amplify, reduce reagent cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The construction of embodiment 1 recombinant engineering bacterium

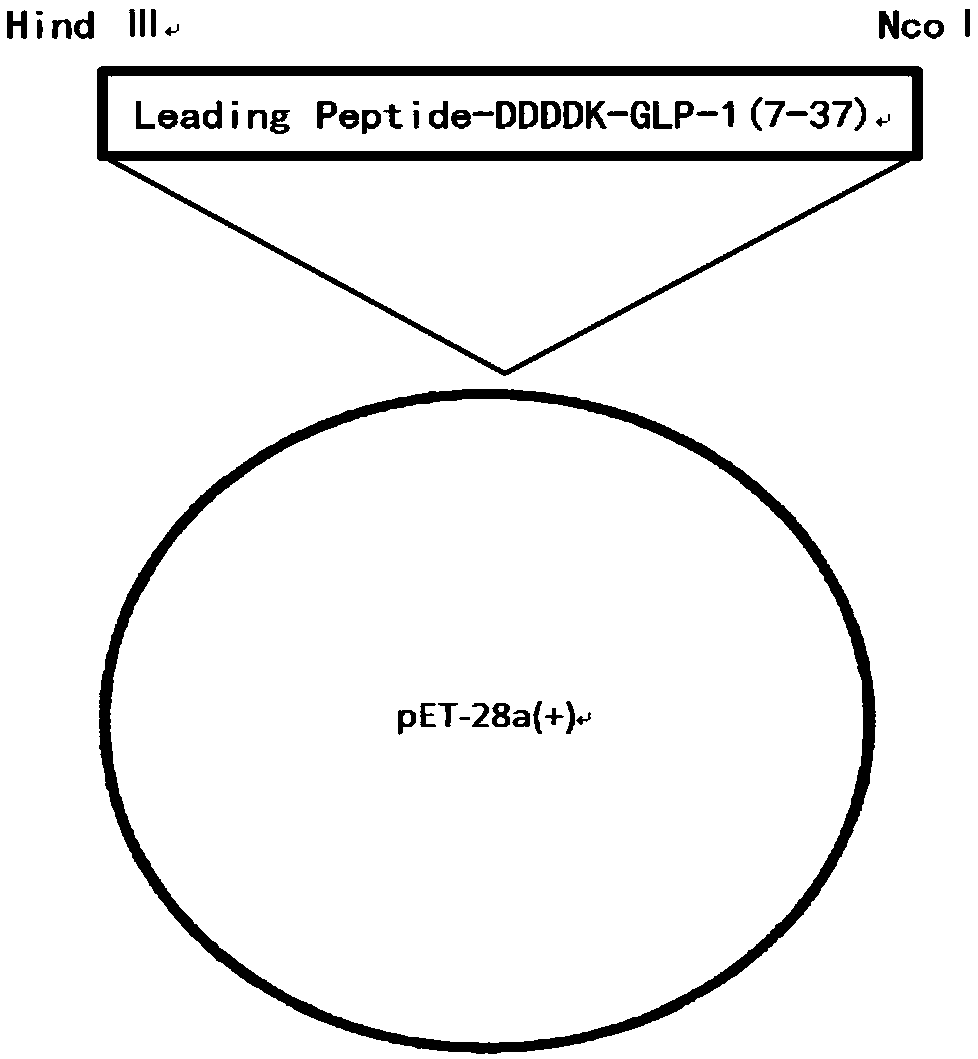

[0035] The gene of Leading Peptide-DDDDK-GLP-1(7-37) fusion protein was synthesized by conventional chemical synthesis method, and the obtained sequence cDNA was inserted into the corresponding plasmid pET-28a(+) through the Hind III / Nco I restriction site In the enzyme cutting site, the constructed recombinant plasmid is as figure 1 As shown, the recombinant plasmid inserted into the gene encoding the Leading Peptide-DDDDK-GLP-1(7-37) fusion protein was transformed into the host Escherichia coli by a conventional chemical transformation method.

Embodiment 2

[0036] Embodiment 2 high-density fermentation

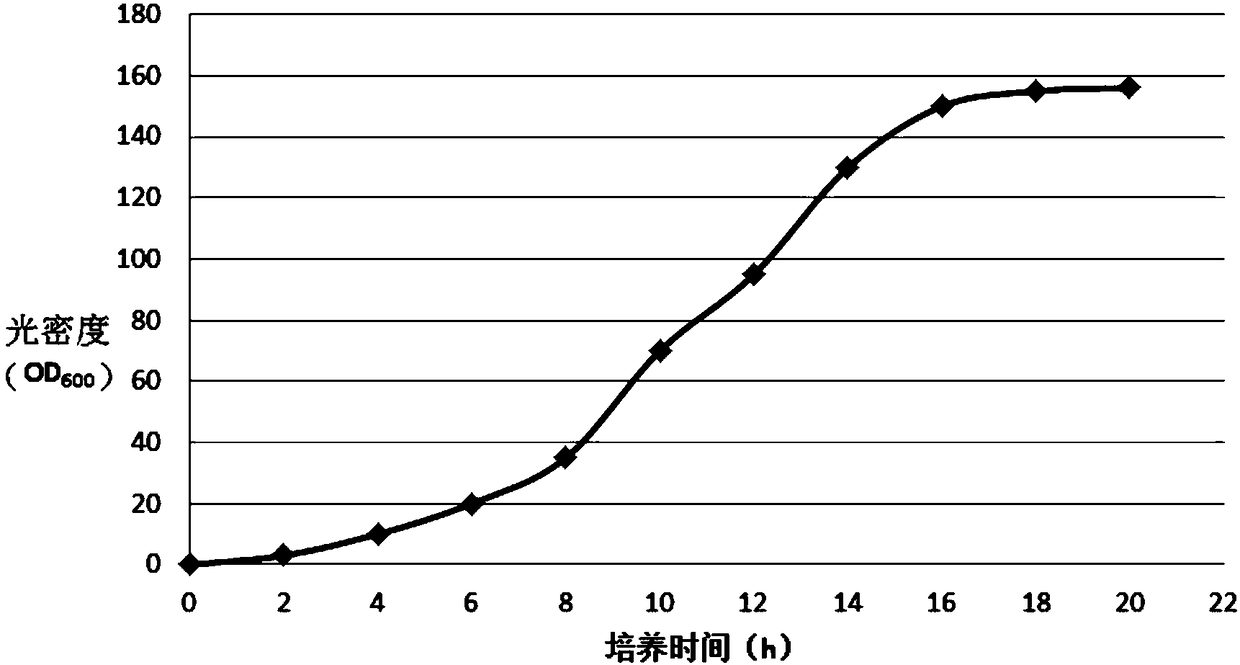

[0037] Inoculate the positive clone of recombinant engineering bacteria obtained in Example 1 in 100mL LB medium, 37 ° C, after 250rpm shaking overnight culture, inoculate in 200mL LB medium according to the ratio of 0.5%, shake culture to OD 600 When the value reaches 10, it is used as a seed solution, and is inserted into 6L of fermentation medium according to the inoculum amount of 1% for high-density cultivation. The initial fermentation temperature is 37°C, the stirring speed is 200rpm, the ventilation rate is 40L / min, and the pH is 6.5. After that, the stirring speed and the maximum ventilation rate are continuously increased to 1000rpm and 80L / min respectively to maintain the dissolved oxygen above 20%. Because of high-density fermentation A large amount of oxygen is needed. If the oxygen supply is insufficient, it will not only inhibit the respiration of the bacteria, limit the growth and reproduction of the bacteria, but...

Embodiment 3

[0044] Embodiment 3 high-density fermentation

[0045] Inoculate the positive clone of recombinant engineered bacteria obtained in Example 1 in 100mL LB medium, 37 ° C, after 250rpm shaking overnight culture, inoculate in 200mL LB medium according to the ratio of 2%, shake culture to OD 600 When the value reaches 4, it is used as a seed liquid, and is inserted into 6L fermentation medium according to 5% inoculum amount for high-density cultivation. The initial fermentation temperature is 37°C, the stirring speed is 200rpm, the ventilation rate is 40L / min, and the pH is 7.3. After that, the stirring speed and the maximum ventilation rate are continuously increased to 1000rpm and 80L / min respectively to maintain the dissolved oxygen above 20%. Because of high-density fermentation A large amount of oxygen is needed. If the oxygen supply is insufficient, it will not only inhibit the respiration of the bacteria, limit the growth and reproduction of the bacteria, but also accumulate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com