Polysilicon purification method and device by reverse induced solidification

A technology of reverse solidification and polycrystalline silicon, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of silicon purity reduction, increase of manufacturing cost, and influence on purification effect, etc., and achieve simple operation, strong controllability, Good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

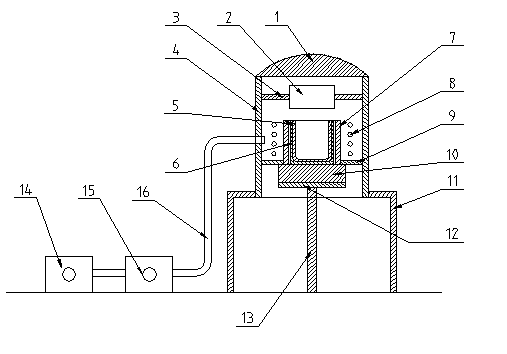

[0024] Such as figure 1 The equipment for purifying polysilicon by reverse induced solidification is shown as an external structure consisting of a furnace cover 1, a furnace body 4 and a support base 11. The purpose of the rod 13 is to drive the crucible to rotate during the purification process, so that the falling powder is evenly sprinkled on the surface of the melt, and at the same time, the crucible moves downward at a certain speed to pull the ingot. The water-cooled tray 12 plays the role of heat dissipation and support. The cooling plate 10 is fixedly installed above the water-cooling tray 12. Its main purpose is to accelerate the heat dissipation at the bottom of the crucible, so that a temperature gradient is formed between the top and the bottom of the crucible, which facilitates the solidification of the melt at the bottom of the crucible to form an ingot. The solidification and heat preservation device is placed on On the heat dissipation plate 10, the solidifica...

Embodiment 2

[0026] The equipment described in Example 1 is used to perform reverse induced solidification to purify polysilicon. First, the induction coil 8 is used to heat the silicon material in the quartz crucible 5 to 1450° C. to melt it to form a silicon melt, and then the power of the induction coil 8 is adjusted. Small, start the water-cooled rotating rod 13 to move downward to pull the ingot, so that the silicon melt is solidified from the bottom of the quartz crucible 5 to the top. When the solidification reaches 80%, rotate the quartz crucible 5 through the water-cooled rotating rod 13, and open the powder falling device at the same time 2. Scatter the high-purity silicon powder into the upper silicon melt with high impurity content. The high-purity silicon powder is used as a nucleating agent to rapidly reverse the solidification of the upper silicon melt. After the solidification is completed, cut off the part obtained by the reverse solidification of the upper layer , the obta...

Embodiment 3

[0032]The equipment described in Example 1 is used to perform reverse induced solidification to purify polysilicon. First, the induction coil 8 is used to heat the silicon material in the quartz crucible 5 to 1500° C. to melt it to form a silicon melt, and then the power of the induction coil 8 is adjusted. Small, start the water-cooled rotating rod 13 to move downward to pull the ingot, so that the silicon melt is solidified from the bottom of the quartz crucible 5 to the top. When the solidification reaches 85%, rotate the quartz crucible 5 through the water-cooled rotating rod 13, and open the powder falling device at the same time 2. Scatter high-purity silicon powder into the upper silicon melt with high impurity content. The high-purity silicon powder acts as a nucleating agent to rapidly reverse solidify the upper silicon melt. After the solidification is completed, cut off the upper layer and reverse solidify. Part, the obtained lower ingot is the high-purity silicon in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com