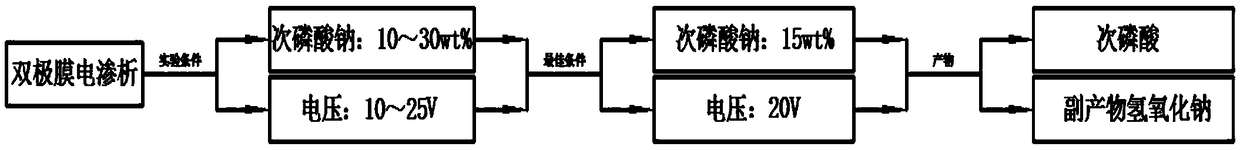

Bipolar membrane electrodialysis method for preparing hypophosphorous acid from sodium hypophosphite

A technology of bipolar membrane electrodialysis and sodium hypophosphite, applied in the direction of electrodialysis, hypophosphorous acid, phosphorus oxyacid, etc., can solve the problems of high energy consumption, complicated and cumbersome ion exchange process, low purity, etc., and achieve high yield efficient production, significant environmental and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

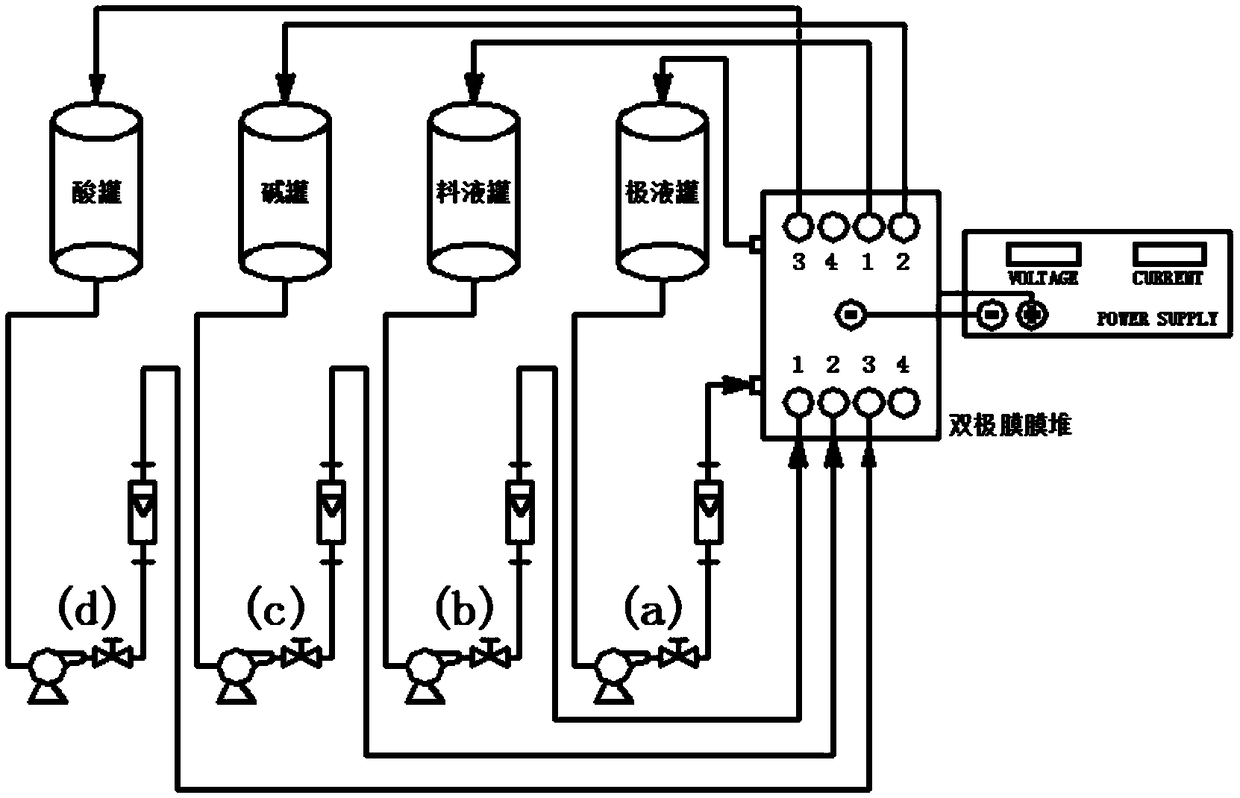

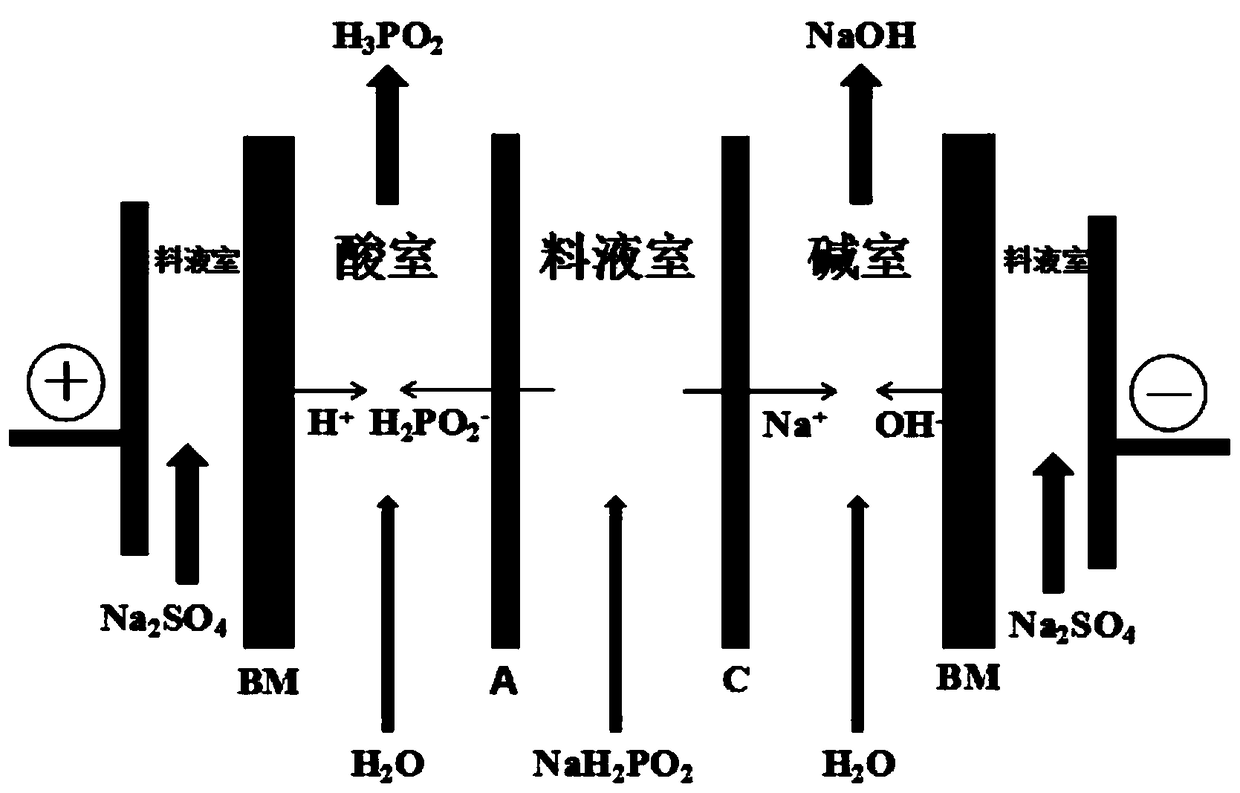

Method used

Image

Examples

Embodiment 1

[0039]Take the membrane stack composed of FBM / AHA / CMB / FBM, add 0.5L of 15wt% sodium hypophosphite feed liquid to the feed liquid tank, turn on the circulation pump and pump it into 5 groups of three-compartment chambers with a size of 9cm×21cm The feed liquid chamber of the bipolar membrane electrodialysis membrane stack, and adjust the flow rate to 20L / h; add 0.5L pure water to the alkali tank and acid tank respectively, turn on the circulation pump to pump it into the alkali chamber and acid tank of the membrane stack chamber, and adjust the flow to 20L / h; add 0.5L of 3wt% sodium sulfate solution to the anode liquid tank, turn on the circulation pump to pump it into the anode liquid chamber of the membrane stack, and run at a flow rate of 20L / h. Turn on the DC power supply and control the voltage to 10V. At this time, the reaction temperature in the compartment is 21.3°C. After 150 minutes of reaction, the acid compartment generates hypophosphorous acid with a yield of 63.34%...

Embodiment 2

[0041] Take a membrane stack composed of FBM / AHA / CMB / FBM, and adjust the voltage to 15V. At this time, the reaction temperature in the compartment is 22.6°C. Other conditions are the same as in Example 1. After 60 minutes of reaction, the acid compartment generates hypophosphorous acid with a yield of 69.58%. , the concentration chamber obtains 3.80% sodium hydroxide solution, the current efficiency is 57.09%, and the energy consumption is 5.09kWh / kg.

Embodiment 3

[0043] Take a membrane stack composed of FBM / AHA / CMB / FBM, adjust the voltage to 20V, the reaction temperature in the compartment is 23.3°C, other conditions are the same as in Example 1, react for 40 minutes, the acid compartment generates hypophosphorous acid, and the yield is 80.06% , the concentration chamber obtains 3.96% sodium hydroxide solution, the current efficiency is 58.41%, and the energy consumption is 4.99kWh / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com