Method for preparing aluminum hypophosphite

A technology of aluminum hypophosphite and sodium hypophosphite, applied in the direction of hypophosphorous acid, phosphorus oxyacid, etc., to achieve the effect of high yield, good quality and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

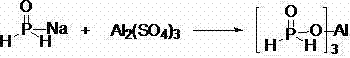

Method used

Image

Examples

Embodiment 1

[0028] Add 7.7 g of sodium hypophosphite and 110 mL of water into a 500 mL four-necked flask equipped with a serpentine reflux condenser, an electric stirrer and a thermometer, stir to dissolve, and add sulfuric acid dropwise to adjust the pH to 3.

[0029] Heat the sodium hypophosphite solution to 40°C, add 50 mL of a solution containing 8.3 g of aluminum sulfate octadecahydrate, and react for 2 h to obtain a white precipitate. Filter, wash, and dry to obtain a white powder product. The yield was 80.9%.

Embodiment 2

[0031] Add 7.7 g of sodium hypophosphite and 110 mL of water into a 500 mL four-neck flask equipped with a serpentine reflux condenser, an electric stirrer and a thermometer, stir to dissolve, and adjust the pH to 3.

[0032] Heat the sodium hypophosphite solution to 50°C, add dropwise 50 mL of a solution containing 8.3 g of aluminum sulfate octadecahydrate, and react for 2 h to obtain a white precipitate. Filter, wash, and dry to obtain a white powder product. The yield was 91.9%.

Embodiment 3

[0034] Add 7.7 g of sodium hypophosphite and 110 mL of water into a 500 mL four-necked flask equipped with a serpentine reflux condenser, an electric stirrer and a thermometer, stir to dissolve, and adjust the pH to 4.

[0035] Heat the sodium hypophosphite solution to 80°C, add dropwise 50 mL of a solution containing 8.3 g of aluminum sulfate octadecahydrate, and react for 2 h to obtain a white precipitate. Filter, wash, and dry to obtain a white powder product. The yield was 95.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com