Fibroin-silver-nanoparticle composite material and preparation method thereof

A technology of silver nanoparticles and composite materials, applied in the field of silk protein-silver nanoparticle composite materials and their preparation, can solve the problems of complicated molding process, affecting the application of polymer-silver nanoparticle composite materials, and high cost, so as to expand the application. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

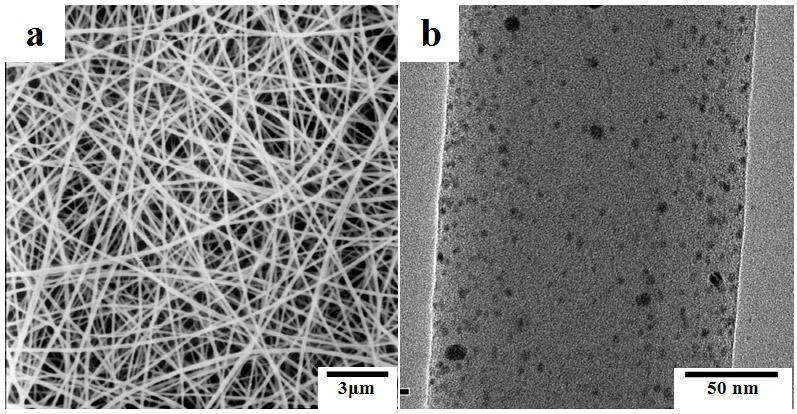

[0032] Example 1: 20 mg of degummed silk precursor was immersed in 5 mL of silver nitrate solution with a concentration of 80 mg / mL and allowed to stand for 30 min, and then the entire reaction system was exposed to a 60 W incandescent lamp for 24 h. The silk is taken out, washed three times with deionized water to remove unreacted silver nitrate, and then dried at room temperature to prepare the silk-silver nanoparticle composite fiber.

Embodiment 2

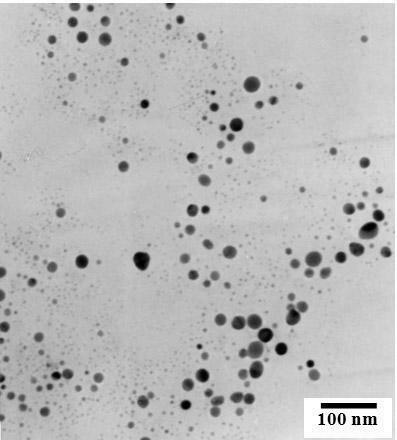

[0033] Example 2: Add 20 mg of silver nitrate to about 5 mL of silk protein aqueous solution with a mass concentration of 12% under stirring, so that the concentration of silver nitrate is 4 mg / mL. Stirring was continued for 10 min to fully dissolve the silver nitrate, and a clear silk protein-silver nitrate mixed solution was obtained. After exposing the mixed solution to sunlight for 3 hours, the mixed solution was cast into a film-forming container, and dried at room temperature to form a film. The prepared membrane was treated with 80% ethanol aqueous solution for 30min, and then the membrane was washed 5 times with deionized water to remove unreacted silver nitrate, and then dried at room temperature to obtain silk protein-silver nanoparticles. particle composite film.

Embodiment 3

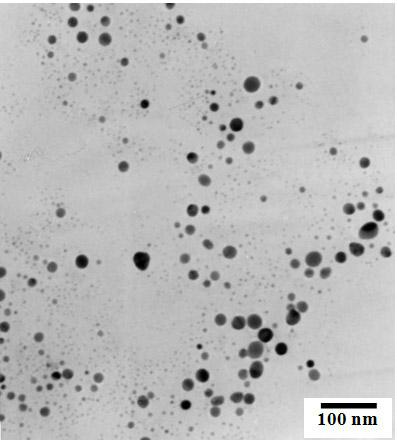

[0034] Example 3: Prepare an aqueous silk protein solution with a mass concentration of 15%, cast the aqueous silk protein solution into a film-forming container, and dry it at room temperature to form a film. The prepared film was treated with 80% ethanol aqueous solution for 30 min, and then dried at room temperature. The silk protein membrane was soaked in a silver nitrate solution with a concentration of 20 mg / mL and allowed to stand for 1 h, and then the entire reaction system was exposed to a 100 W incandescent lamp for 36 h. The membrane was taken out, washed four times with deionized water to remove unreacted silver nitrate, and then dried at room temperature to prepare a silk protein-silver nanoparticle composite membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com